Photocurable propellant and preparation method thereof

A propellant and light-curing technology, which is used in offensive equipment, explosives processing equipment, non-explosive/non-thermal agent components, etc., can solve the problems of low mechanical properties of solid propellant samples at room temperature, avoid mechanical contact friction, High safety and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Put the metered photocurable resin, active diluent, photoinitiator, metal combustion agent, functional additive and other raw materials into the container of the acoustic resonance mixing equipment, and mix at an acceleration of 60G~70G for 5min~10min; Add metered oxidant to the mixing container for mixing, the acceleration is 55G ~ 65G, and the mixing time is 10min ~ 15min to obtain photocurable propellant slurry; transport the propellant slurry to a 3D printing cylinder with vacuum function, and process it Vacuum degassing; and then adopt the 3D printing process of pneumatic extrusion, ultraviolet lamp curing, and layer-by-layer superimposition to prepare light-curing propellant samples.

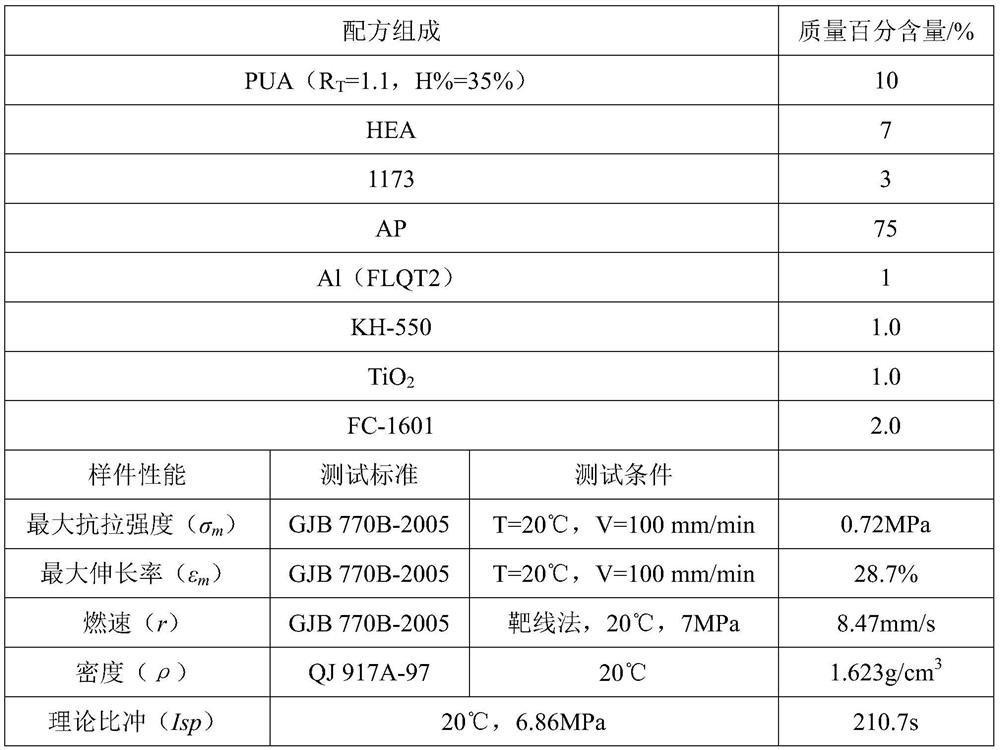

[0029] The specific formulation and performance of the photocurable propellant are shown in Table 1 below.

[0030] Table 1

[0031]

Embodiment 2

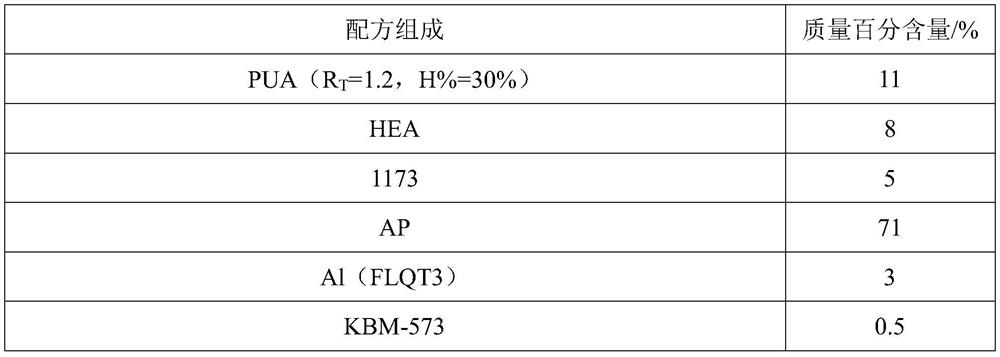

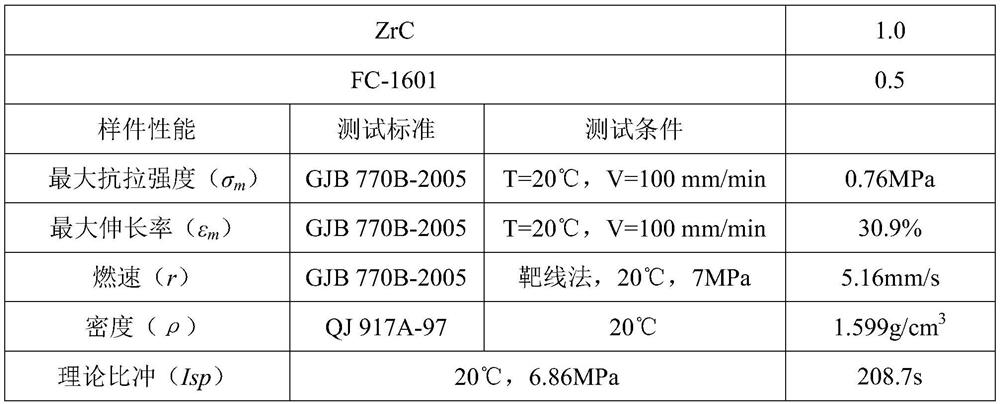

[0033] The specific formulation and performance of the photocurable propellant are shown in Table 2 below. Concrete preparation method is with embodiment 1.

[0034] Table 2

[0035]

[0036]

Embodiment 3

[0038] The specific formula and performance of the photocurable propellant are shown in Table 3 below. Concrete preparation method is with embodiment 1.

[0039] table 3

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com