Method for quickly separating polar components in frying oil on line

A polar component and frying oil technology, applied in the detection field, can solve the problems of sample loss, high cost, cumbersome steps, etc., and achieve the effect of high accuracy, low cost and fast separation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

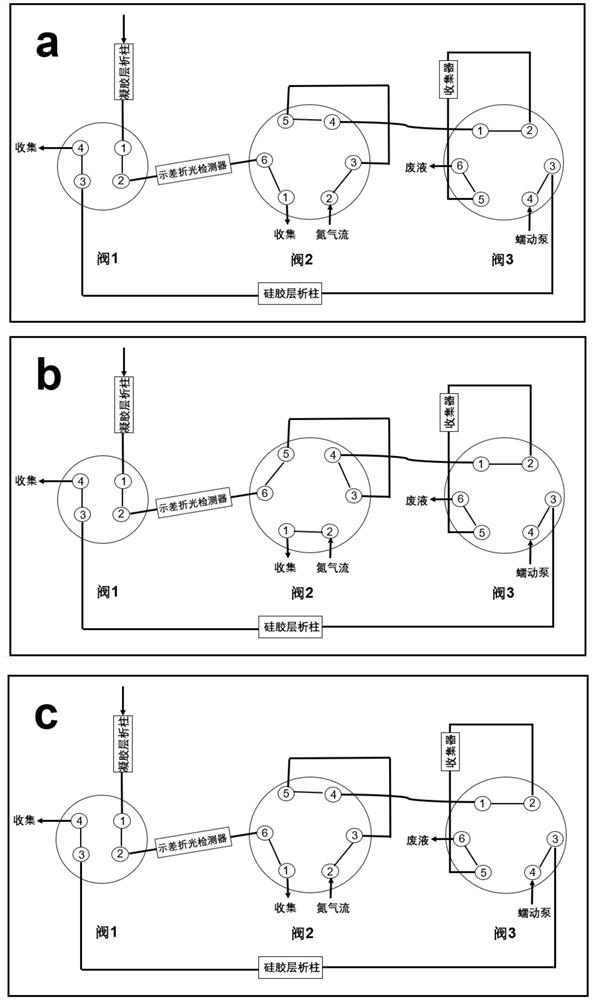

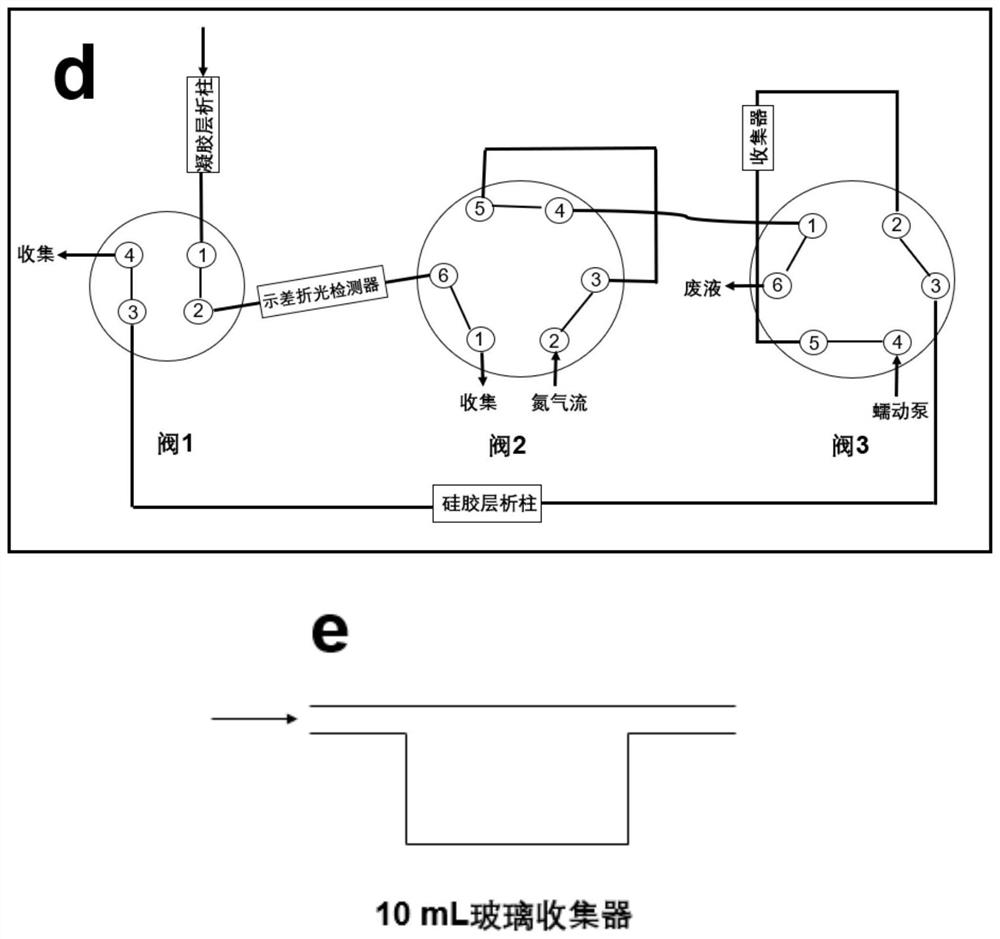

[0032] Example 1: A device for quickly separating polar components in frying oil online

[0033] Such as figure 1 Said, the device is composed of a gel chromatography column, a differential refraction detector and a silica gel chromatography column connected in series, the gel chromatography column, the differential refraction detector, The silica gel chromatography columns are connected in series, and the outlet of the gel chromatography column, the inlet of the differential refraction detector and the outlet of the silica gel chromatography column are connected to the same multi-way valve; the outlet of the differential refraction detector and the inlet of the silica gel chromatography column pass through at least two The multi-way valve is connected; the multi-way valve connected to the outlet of the differential refraction detector is connected with a nitrogen interface; the multi-way valve connected to the inlet of the silica gel chromatography column is connected with an...

Embodiment 2

[0035] Embodiment 2: A kind of method for rapidly separating polar components in frying oil

[0036](a) Accurately weigh 200 mg of frying oil stored at -20°C, dissolve it in a little dichloromethane and load it on a gel chromatography column (Sephadex LH-20 filler), add eluent (methanol: dichloromethane Methane=2:3) separation. Such as figure 1 As described in a, the gel chromatography column and the differential refractive index detector are connected in series through valve 1. The gel column chromatography first separates the components with large molecular weight differences, and then enters the differential refractive index detector through valve 1 for detection to obtain TGO. , TGD, the flow rate of the gel column is one drop per second. From the 10th minute, the polar substances will flow out separately. The first flow out is TGO (10-15min), followed by TGD (15-19.5min).

[0037] (b) if figure 1 As described in b, after TGD is collected, switch valve 2 so that TG and ...

Embodiment 3

[0040] Embodiment 3: A kind of method for detecting polar component content in frying oil

[0041] Adopt the method for embodiment 2 to separate the polar substance in the frying oil, obtain six kinds of components, detect its content through differential refraction detector, concrete steps are as follows:

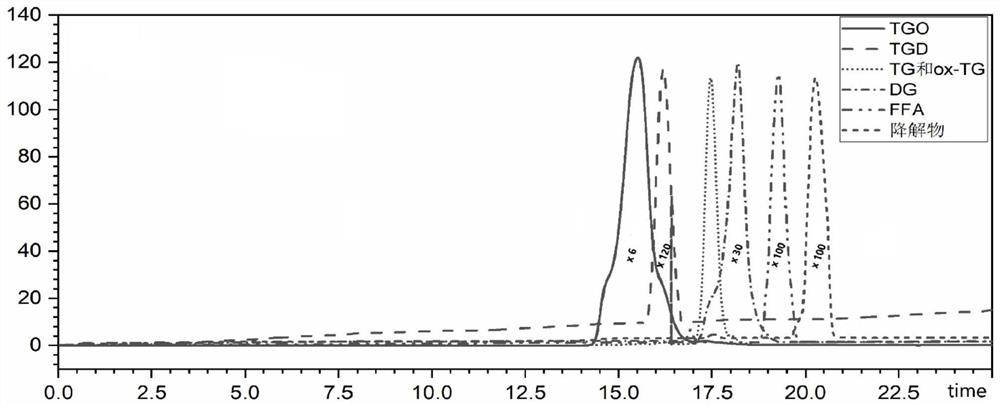

[0042] (a) Accurately weigh 0.0100 g of the six components obtained in Example 2 and dissolve them in 1.0 mL of tetrahydrofuran, and then configure them to have concentrations of 0.01 g / mL, 0.008 g / mL, 0.006 g / mL, and 0.004 g / mL. mL, 0.002g / mL, 0g / mL standard solution (or 0.01g / mL, 0.0075g / mL, 0.005g / mL, 0.0025g / mL, 0g / mL), each component can be obtained by differential refractive index detector The standard curve as Figure 5 As shown, R 2 All are greater than 0.99; the differential refractive index detector is in the standard mode; the allowable value of drift is 5000nRIU / h; the allowable value of noise is 500nRIU; the temperature is 35°C; the flow rate is 2.4mL / min. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com