Negative pole piece and lithium ion battery comprising negative pole piece

A negative electrode, lithium ion technology, applied in the direction of negative electrode, secondary battery, battery electrode, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

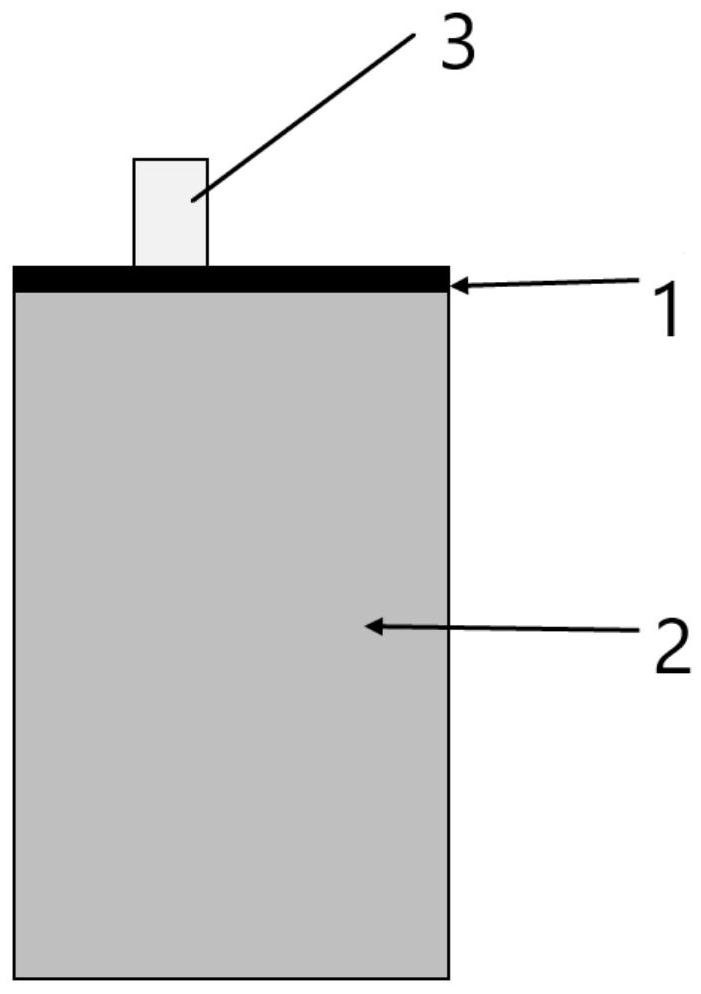

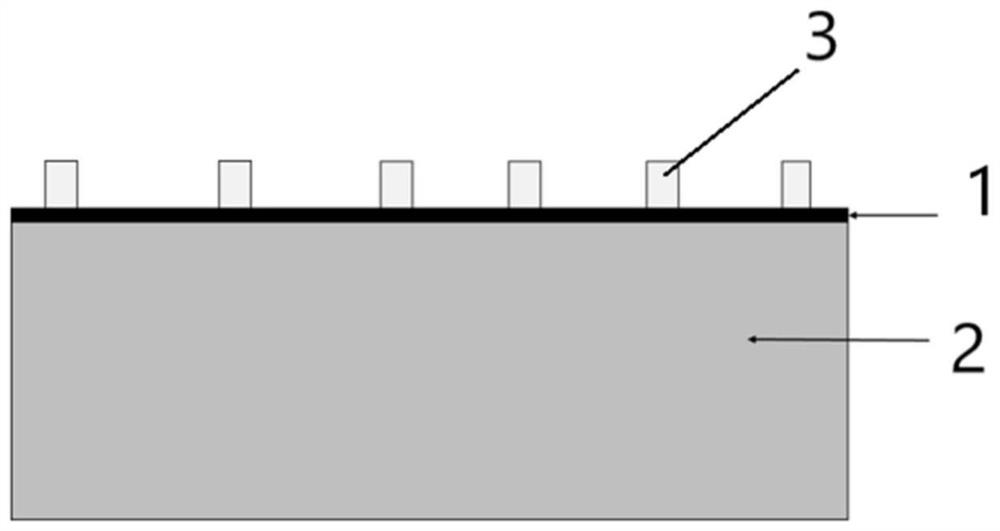

Image

Examples

Embodiment 1

[0066] (1) Preparation of the first coating area and the third coating area slurry

[0067] 76g of hard carbon, 19g of silicon oxide, 2g of styrene-butadiene rubber, 1.5g of sodium carboxymethylcellulose and 1.5g of conductive carbon black were mixed and dispersed in deionized water to obtain the slurry for the first coating area, which was designated as T1.

[0068] (2) Preparation of the second coating area and the fourth coating area slurry

[0069] Mix and disperse 95g of graphite, 2g of styrene-butadiene rubber, 1.5g of sodium carboxymethyl cellulose and 1.5g of conductive carbon black in deionized water to obtain the slurry for the second coating area, which is denoted as B1.

[0070] (3) Preparation of negative electrode sheet

[0071] The above-mentioned slurry T1 and slurry B1 are coated on the first surface of the negative electrode current collector at the same time, wherein the slurry T1 is coated on the first coating area of the negative electrode current colle...

Embodiment 2

[0077] Embodiment 2 differs from Embodiment 1 in that:

[0078] In step (1), 47.5 g of hard carbon and 47.5 g of silicon oxide were used to prepare lithium ion battery C2.

Embodiment 3

[0080] Embodiment 3 differs from Embodiment 1 in that:

[0081] In step (1), 57g of hard carbon and 38g of silicon oxide were used to prepare lithium ion battery C3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com