Method for producing a micromechanical device having inclined optical windows, and corresponding micromechanical device

A manufacturing method and technology of optical windows, applied in the manufacture of microstructure devices, processes for producing decorative surface effects, microelectronic microstructure devices, etc., can solve structural damage, lack of optical quality, and very expensive three-dimensional structures, etc. problem, to achieve cost-effective, damage-prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

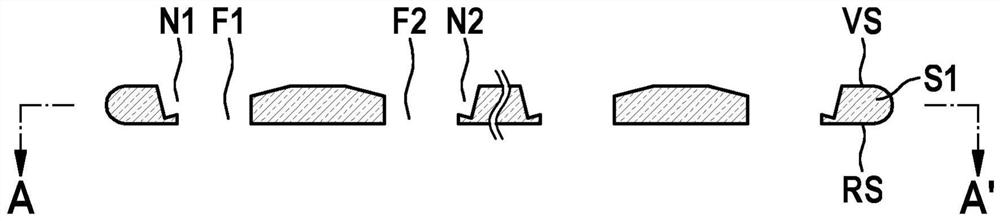

[0033] In the figures, identical reference numbers indicate identical or functionally identical elements.

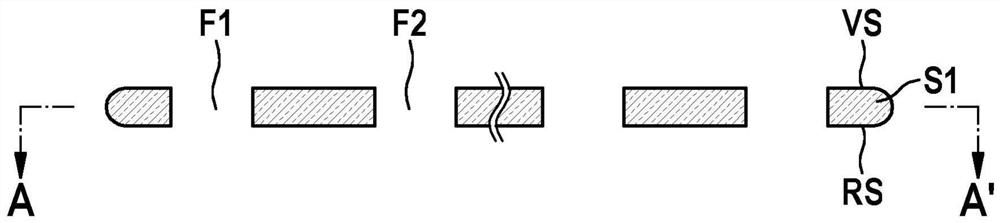

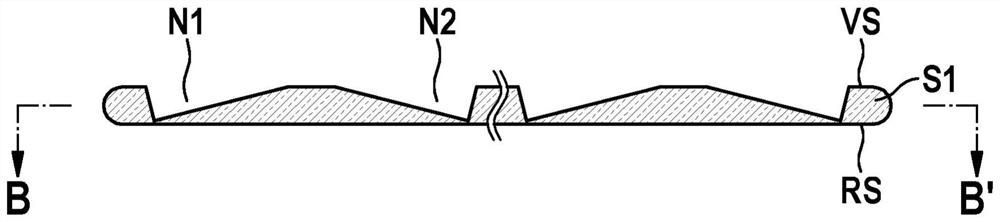

[0034] Figure 1a )-e) are schematic cross-sectional views for explaining the manufacturing method for a micromechanical device with a tilted optical window and the corresponding micromechanical device according to the first embodiment of the present invention, and figure 2 is a schematic top view of the micromechanical device according to the first embodiment of the present invention.

[0035] The micromechanical device with inclined optical windows according to the first embodiment can be used, for example, as a protective wafer device for a micromechanical micromirror scanner device.

[0036] The production of the micromechanical device takes place on a wafer plane, but the production is not restricted thereto and can also take place on another substrate plane. To simplify the illustration, only the production of two tilted optical windows is shown here, but a large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com