A kind of preparation method of TPU expanded beads and product thereof

A technology for foaming beads and particles, applied in the field of thermoplastic polyurethane elastomer foam materials, can solve the problems of unstable density of TPU foam beads, uneven cell size, low production efficiency, etc. Achieve the effect of reducing equipment investment, improving performance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

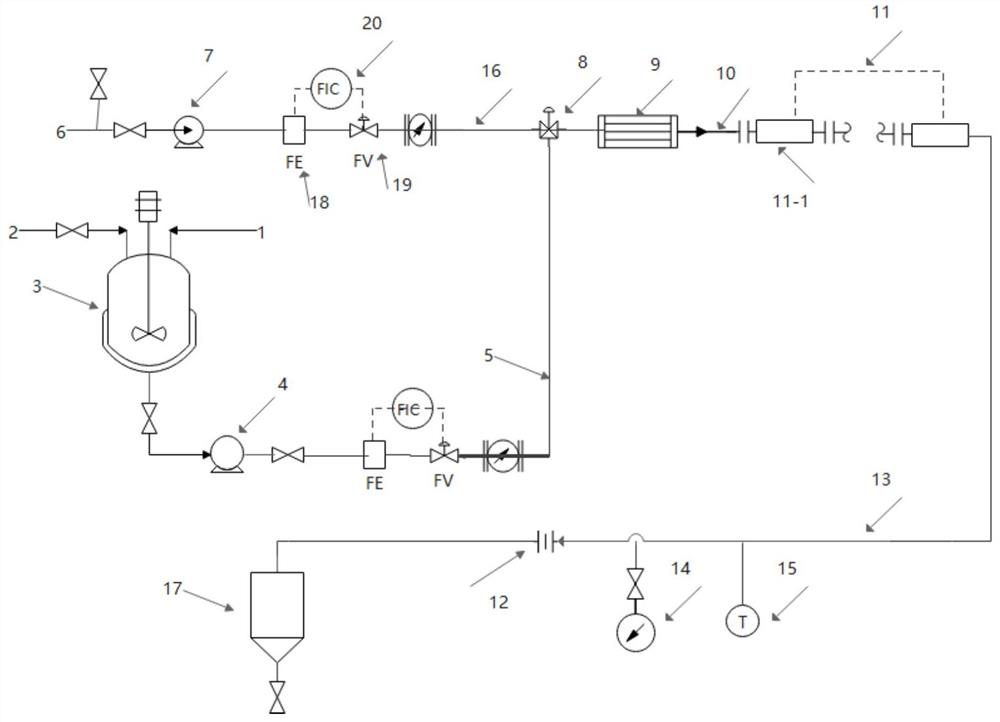

[0054] The technological process and system of the preparation method of TPU expanded beads of the present invention are as figure 1 shown, including steps:

[0055] (1) Continuously add the TPU particles 1 and water 2 into the reaction kettle 3 after metering respectively, and stir to form a uniform suspension;

[0056] (2) Measure above-mentioned suspension and foaming agent 6 respectively, and transport to three-way mixing valve 8 to form mixture in pipeline 5,16 by pump 4,7 respectively; , flow valve 19, flow indicator controller 20 for metering control;

[0057] (3) above-mentioned mixture is delivered in the heat exchanger 9, be warmed up to foaming temperature;

[0058] (4) The mixture that reaches the foaming temperature is transported to the multi-stage impregnation container 11 through the pipeline 10, and the foaming agent is gradually impregnated into the inside of the TPU particles, and finally reaches the dissolution balance;

[0059] The multi-stage immersion...

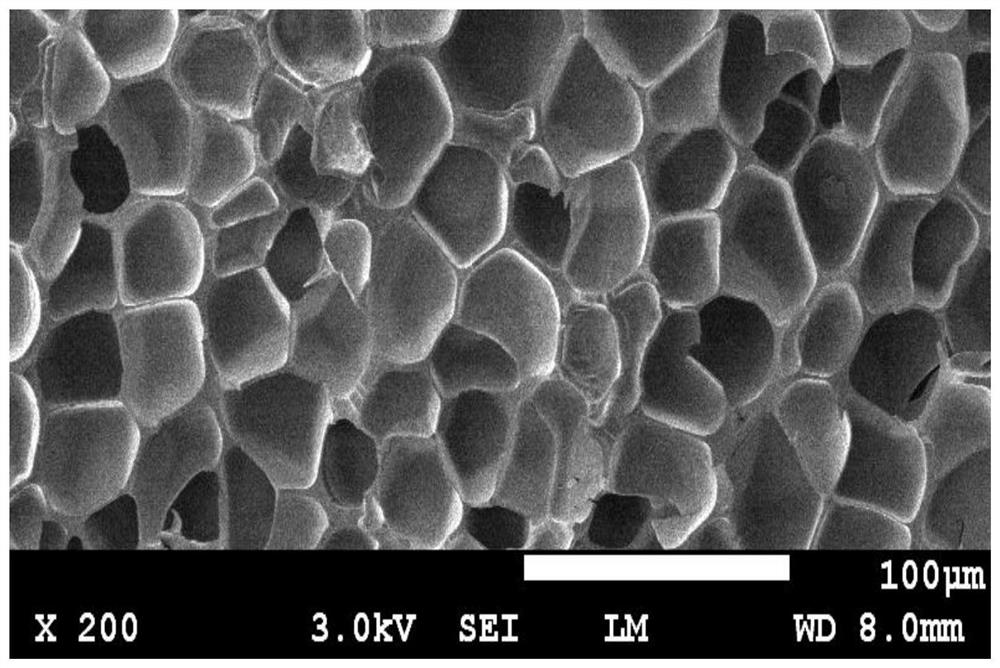

Embodiment 1

[0065] A preparation method of TPU foam beads, comprising the steps of:

[0066] (1) Measure the polyether-type TPU particles 1 and water 2 with a Shore hardness of 75A and a Tm of 160°C through a weight-loss feeding system and a liquid flow meter, respectively, and control the mass ratio of polyether-type TPU particles 1 and water 2 to 1:1, and then continuously added to the 200L reactor 3, and set the stirring speed of the reactor to 45Hz, so that the above TPU particles and water form a uniform suspension;

[0067] (2) The above-mentioned suspension is transported to the three-way mixing valve 8 through the pipeline 5 according to the mass flow rate of 150g / s by the pump 4, and the foaming agent carbon dioxide 6 is transported to the three-way mixing valve by the pump 7 according to the mass flow rate of 15g / s. Pass the mixing valve 8 and mix with the suspension to form a mixture;

[0068] (3) Transport the above-mentioned mixture to the heat exchanger 9 to raise the tempe...

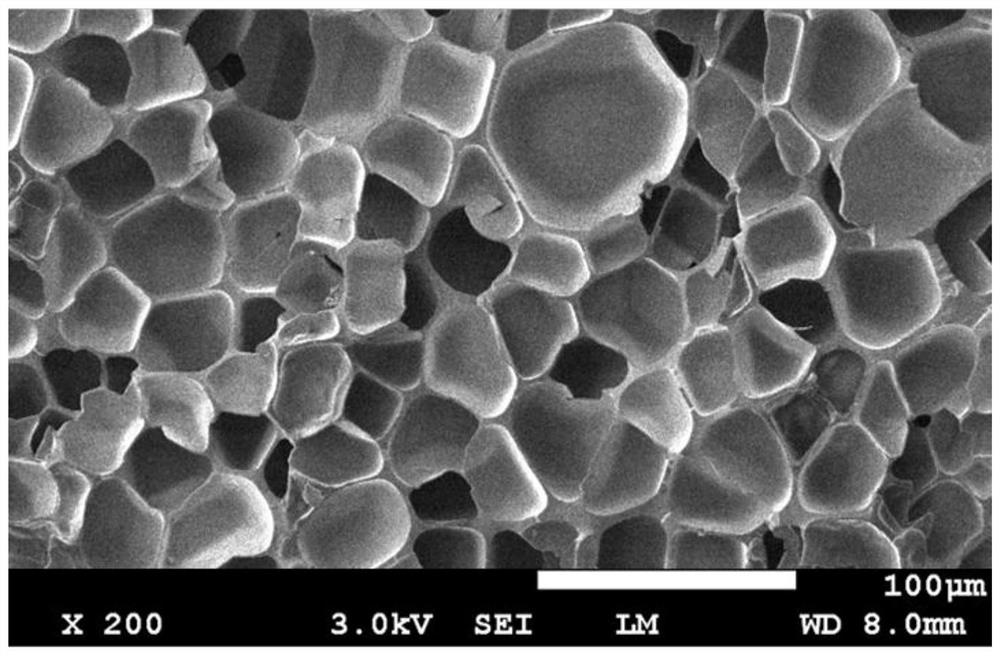

Embodiment 2

[0073] A preparation method of TPU foam beads, comprising the steps of:

[0074] (1) Measure the polyester TPU particles 1 and water 2 with a Shore hardness of 95A and a Tm of 200°C through a weight-loss feeding system and a liquid flow meter, respectively, and control the mass ratio of polyester TPU particles 1 and water 2 to 1:5, and then continuously added to the 200L reactor 3, and set the stirring speed of the reactor to 45Hz, so that the above-mentioned TPU particles and water form a uniform suspension;

[0075] (2) The above-mentioned suspension is transported to the three-way mixing valve 8 through the pipeline 5 according to the mass flow rate of 1500g / s by the pump 4, and the blowing agent nitrogen 6 is transported to the three-way mixing valve by the pump 7 according to the mass flow rate of 125g / s. Pass the mixing valve 8 and mix with the suspension to form a mixture;

[0076] (3) Transport the above-mentioned mixture to the heat exchanger 9 to raise the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com