Plastic casing and preparation method

A plastic shell and transparent plastic technology, applied in polyurea/polyurethane coatings, other household appliances, household appliances, etc., to achieve the effects of improving life expectancy, improving product pass-through rate, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0033] Such as image 3 , 4 The shown plastic shell 6 includes a light-shielding layer 5, a reflective layer 4, a shell layer 1, a texture layer 2 and a hardened layer 3 in sequence. Layer 3 is located outside the shell layer 1 of the plastic shell. The thickness of the shell layer 1 is 0.3-5.0mm, and the thickness of the hardened layer 3 is 5-35um. Of course, the thickness of the shell layer and the hardened layer can also be set according to actual needs.

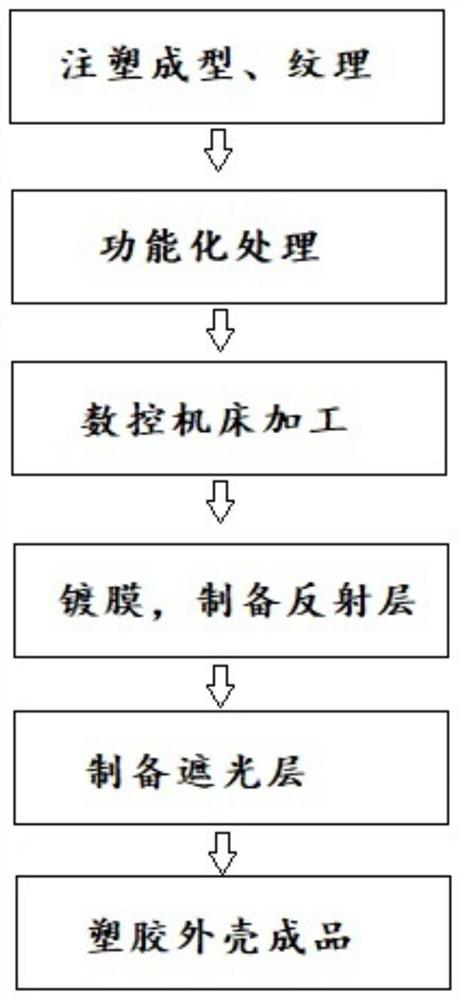

[0034] Such as figure 1 As shown in the flow chart, the specific steps of the above-mentioned method for preparing a plastic shell are as follows:

[0035] Step 1: Injection molding, according to different actual needs, use optical-grade transparent plastic, and use textured metal mold cores for injection molding. The injection molding process is filled with injection molding. The injection molding conditions are: temperature 100-350 ° C The pressure is 10-190Mpa, the pressure of the pressure-holding molding is 10-98MP...

specific Embodiment approach 2

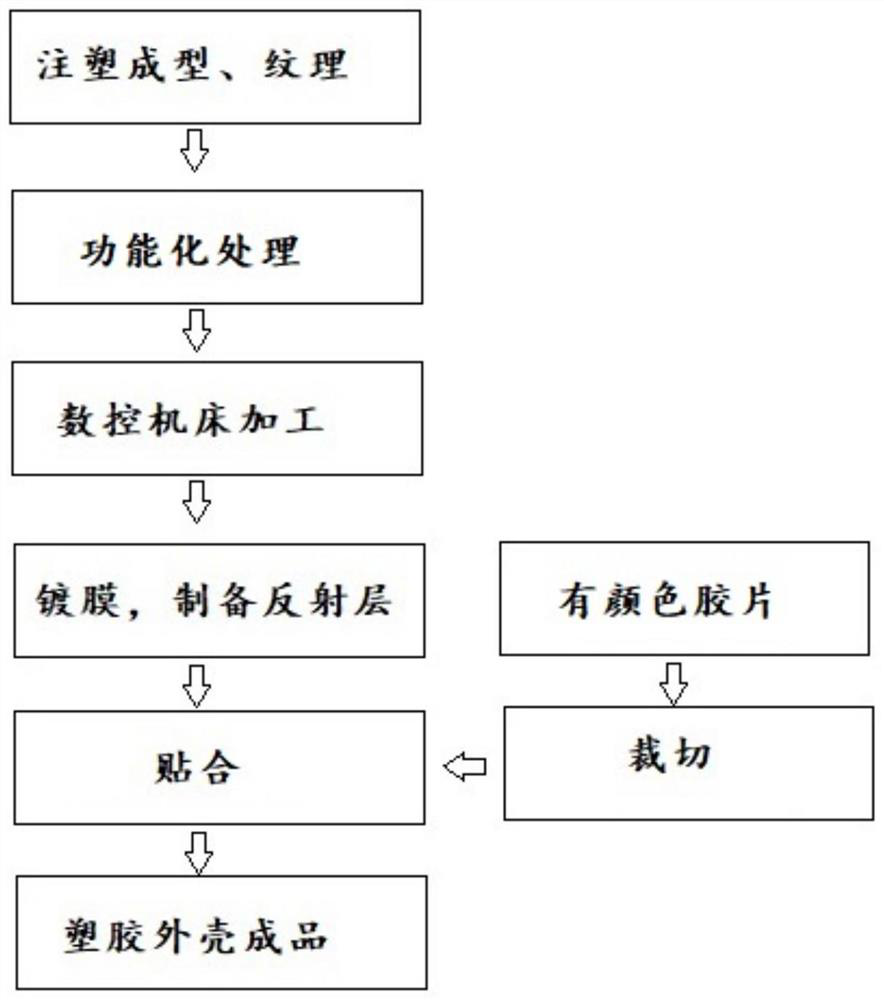

[0042] The setting conditions of specific implementation mode 2 and specific implementation mode 1 are basically the same, the main difference is that: if figure 2 As shown, when preparing the light-shielding layer in step five, the colored film with light-shielding effect is cut and attached to the plastic shell to form the light-shielding layer. Among them, the colored film is a viscous glue layer and colored plastic film or an explosion-proof film with silk screen colored ink. When the colored film is bonded to the plastic shell, it is vacuum bonded, and the bonding temperature is 10-190 ° C. . In this embodiment, the viscous glue layer and colored plastic film are high-temperature-resistant glue and black PET plastic film, and the bonding temperature is 100°C. Of course, other equivalent materials can also be used as the colored film.

specific Embodiment approach 3

[0044] The setting conditions of the third embodiment are basically the same as those of the first embodiment, the main difference is that in the first step, the texture is formed on the outer surface of the plastic casing and the middle frame. At the same time, the injection molding conditions in this example are as follows: temperature is 350°C, injection pressure is 190Mpa, pressure-holding molding pressure is 98MPa, pressure-holding molding time is 180s, and the thickness of the plastic shell after injection molding is 5.0mm. The conditions for forming a functional coating on the surface of the plastic shell in step 2 are set as follows: baking by infrared rays at a baking temperature of 145° C. for 120 minutes to form a 40um functional coating on the surface of the plastic shell. During the CNC machine tool processing in step 3, the spindle speed of the CNC machine tool is 90000 rpm, and the feed rate is 3500 mm / min. In step 4, a mask is set, and a reflective layer is pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com