A kind of cyan silicon nitride ceramics and preparation method thereof

A technology of silicon nitride ceramics and silicon nitride powder, which is applied in the field of cyan silicon nitride ceramics and its preparation, and ceramic preparation, can solve the problems of monotonous color of silicon nitride ceramics and darkening of the color of silicon nitride ceramics, and achieve cost reduction. Low, non-destructive performance, easy to manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

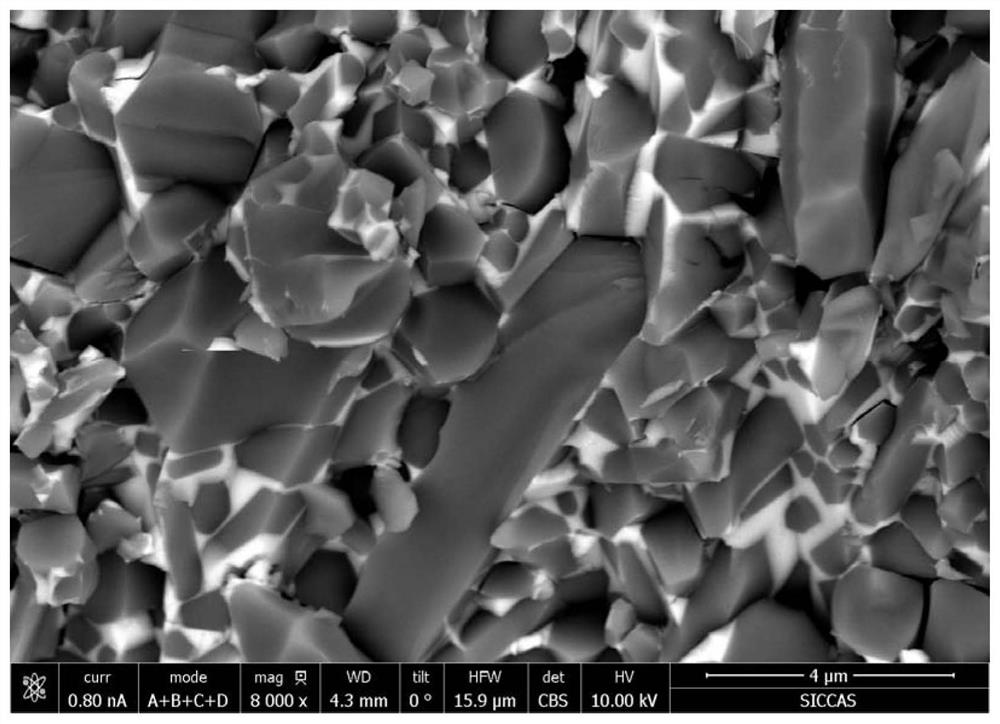

[0040] Add 61.52g of silicon nitride powder, 3.23g of neodymium oxide colorant, 0.7g of PVB binder and 5.26g of sintering aid magnesium oxide-YAG powder in 140g of absolute ethanol, and the weight ratio of magnesium oxide and YAG phosphor is 1:6. After ball milling on a planetary ball mill at a speed of 380r / min for 3 hours, the suspension was poured out, and after drying to remove alcohol, the ceramic powder was ground and passed through a 100-mesh sieve, and prepared into 50×50×5mm by isostatic pressing. Ceramic bodies. Under vacuum, heat up to 900°C at a rate of 3°C / min and hold for 1 hour to complete debonding. After slow debonding, in a carbon tube furnace, heat at a rate of 5°C / min to 1800°C, and hold in a nitrogen atmosphere for 2 hours to achieve sintering . Can get dense, uniform color cyan silicon nitride ceramic sheet;

[0041] The density of the sintered cyan silicon nitride ceramic sheet measured by the Archimedes drainage method is 97.71%. The thermal conduct...

Embodiment 2

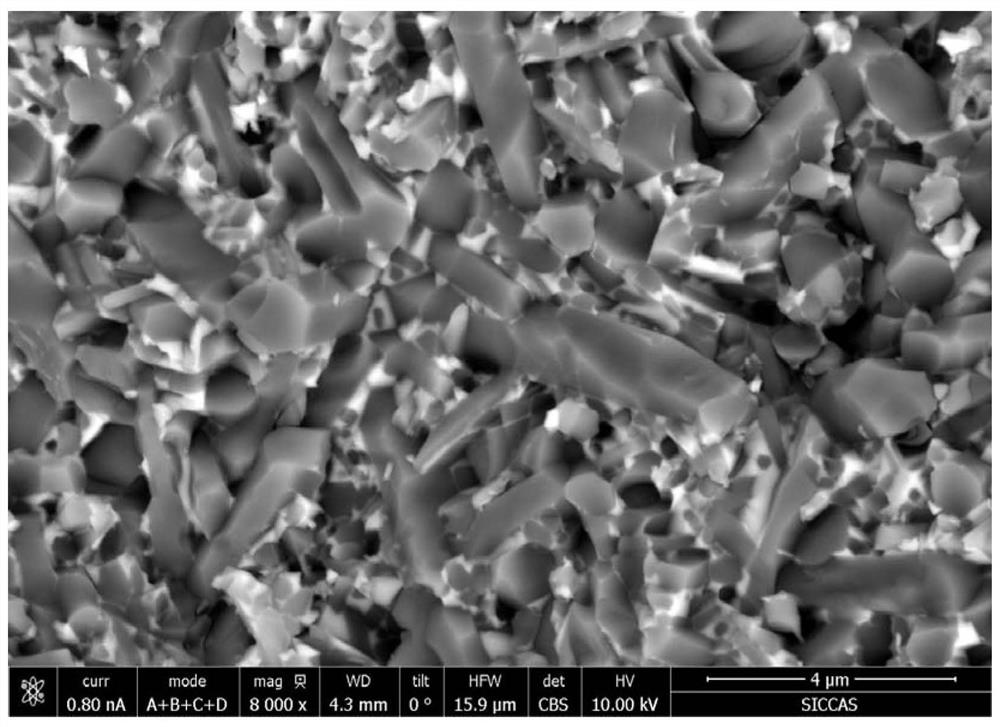

[0043] Add 60.99g of silicon nitride powder, 3.11g of neodymium oxide colorant, 0.7g of PVB binder and 5.89g of sintering aid magnesium oxide-YAG powder in 140g of absolute ethanol, and the weight ratio of magnesium oxide and YAG powder is 1 :8. After ball milling on a planetary ball mill at a speed of 380r / min for 3 hours, the suspension was poured out, and after drying to remove alcohol, the ceramic powder was ground and passed through a 100-mesh sieve, and prepared into 50×50×5mm by isostatic pressing. Ceramic bodies. Under vacuum, heat up to 900°C at a rate of 3°C / min and hold for 1 hour to complete debonding. After slow debonding, in a carbon tube furnace, heat at a rate of 5°C / min to 1800°C. In a nitrogen atmosphere, hold for 2 hours. sintering. Can get dense, uniform color cyan silicon nitride ceramic sheet;

[0044] The density of the sintered cyan silicon nitride ceramic sheet measured by the Archimedes drainage method is 97.15%. The thermal conductivity of silico...

Embodiment 3

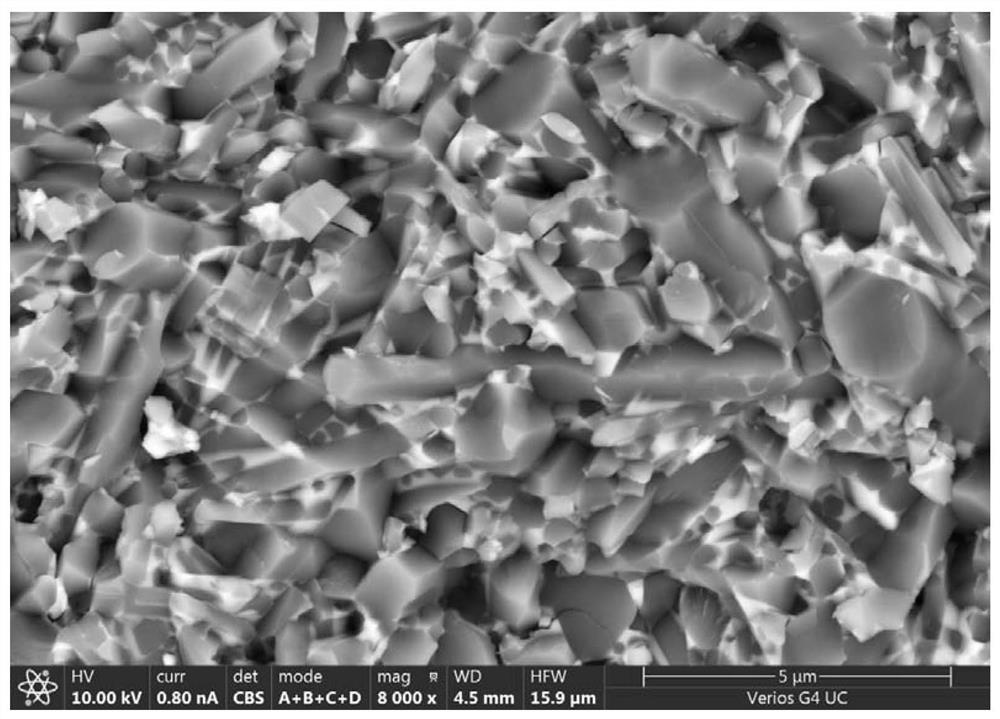

[0046] Add 65.60g of silicon nitride powder, 3.38g of neodymium oxide colorant, 0.7g of PVB binder and 1.01g of sintering aid magnesium oxide into 140g of absolute ethanol. After ball milling on a planetary ball mill at a speed of 380r / min for 3 hours, the suspension was poured out, and after drying to remove alcohol, the ceramic powder was ground and passed through a 100-mesh sieve, and prepared into 50×50×5mm by isostatic pressing. Ceramic bodies. Under vacuum, heat up to 900°C at a rate of 3°C / min and hold for 1 hour to complete debonding. After slow debonding, in a carbon tube furnace, heat at a rate of 5°C / min to 1800°C, and hold in a nitrogen atmosphere for 2 hours to achieve sintering . Can get dense, uniform color cyan silicon nitride ceramic sheet;

[0047] The density of the sintered cyan silicon nitride ceramic sheet measured by the Archimedes drainage method is 98.12%. The thermal conductivity of silicon nitride ceramics measured by laser thermal conductivity me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com