Nitrogen-containing two-dimensional polymer film as well as preparation method and application thereof

A polymer film and general formula technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, chemical/physical processes, etc., can solve problems such as separation, difficult materials, and difficult cleaning. Achieve the effect of large horizontal scale and thin thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1. In container A, dissolve 92.3mg of cyanuric chloride (CAS number: 108-77-0, Aladdin’s reagent) in 100mL-16°C toluene to obtain an organic solution;

[0050] 2. In container B, dissolve 81.1mg of p-phenylenediamine (CAS No.: 106-50-3, Aladdin’s reagent) and 200mg of potassium hydroxide in 100mL of water to obtain an alkaline solution. Put the alkaline solution at -16°C Under rapid freezing;

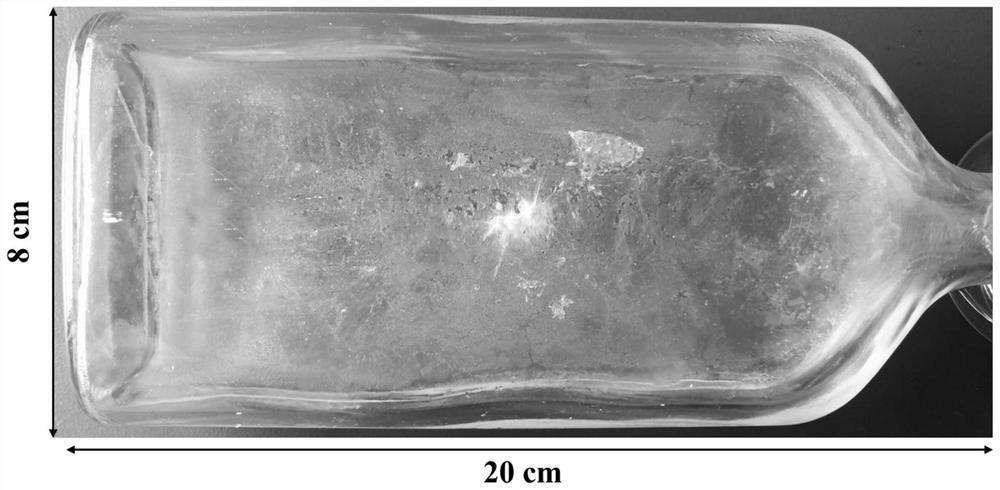

[0051] 3. Pour the organic solution in container A into container B, and place container B at -16°C for 30 days. After standing, pour out the solution above the ice in container B, and use 50mL-16°C Gently wash the ice surface in container B with toluene three times, and melt the ice in container B to obtain a nitrogen-containing two-dimensional polymer film suspended on the water surface.

[0052] 4. Make multiple parallel samples at a time according to the above method, which is convenient for a series of tests later.

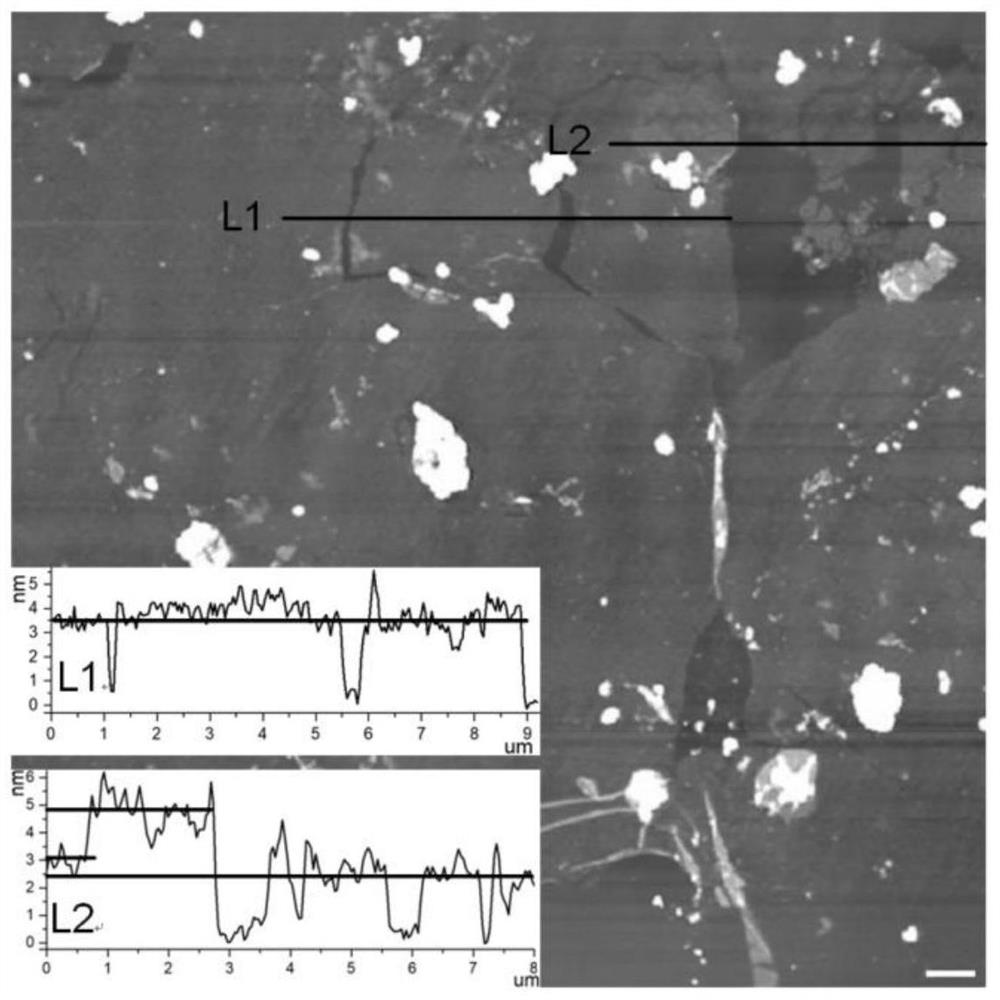

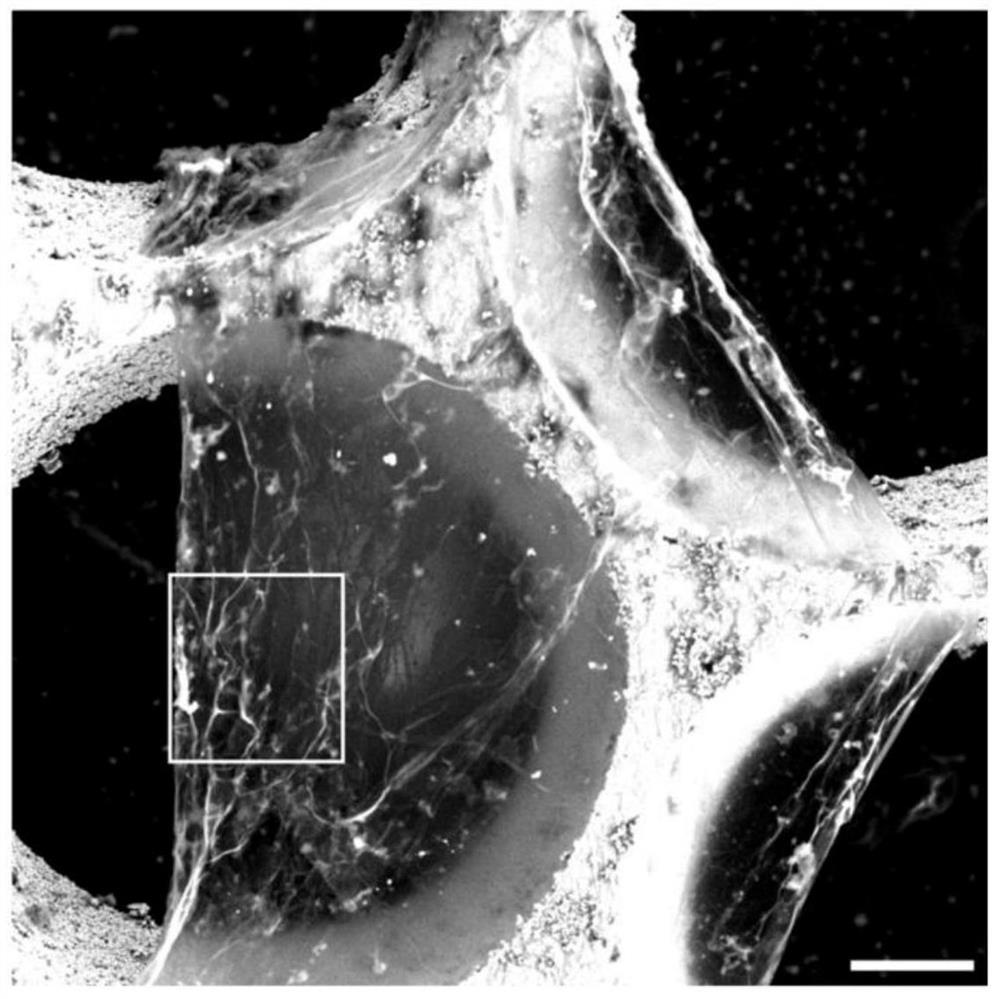

[0053] The nitrogen-containing two-dimensional polymer f...

Embodiment 2

[0068] 1. In container A, dissolve 92.3mg of cyanuric chloride (CAS number: 108-77-0, Aladdin’s reagent) in 100mL-16°C toluene to obtain an organic solution;

[0069] 2. In container B, dissolve 116.3mg of 1,3,5-triaminobenzene trihydrochloride (CAS No.: 638-09-5, Aladdin’s reagent) and 200mg of potassium hydroxide in 100mL of water to obtain alkaline Solution, quickly freeze the alkaline solution at -16°C;

[0070] 3. Pour the organic solution in container A into container B, and place container B at -16°C for 30 days. After standing, pour out the solution above the ice in container B, and use 50mL-16°C Gently wash the ice surface in container B with toluene three times, and melt the ice in container B to obtain a nitrogen-containing two-dimensional polymer film suspended on the water surface.

[0071] 4. Make multiple parallel samples at a time according to the above method, which is convenient for a series of tests later.

[0072] The nitrogen-containing two-dimensional p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com