Method for preparing organic fertilizer for rice from kitchen waste and sawdust through combined composting

A technology of kitchen waste and organic fertilizer, which is applied in the direction of organic fertilizer, fertilizer mixture, phosphate fertilizer, etc., can solve the problems of increasing fertilizer quality, shortening composting time, and difficulty in heating up the process, so as to increase organic matter content, shorten fermentation time, and improve Effects on Yield and Taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

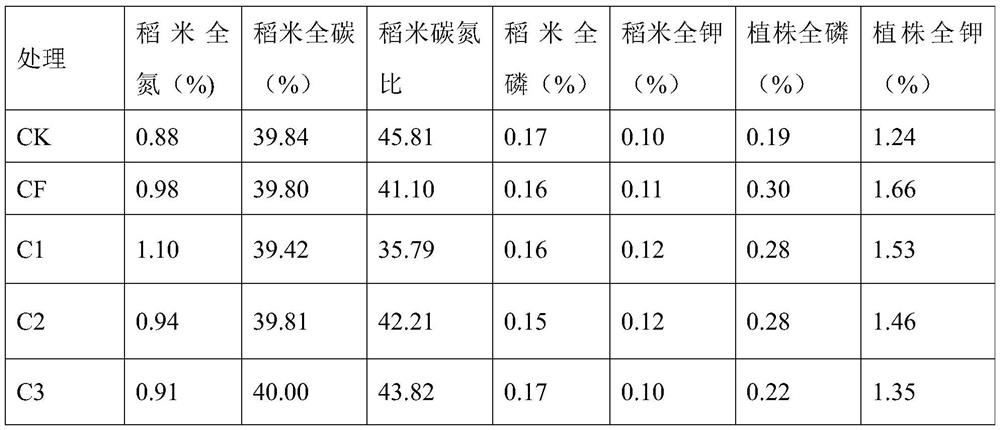

Examples

Embodiment 1

[0023] Step 1: The original kitchen materials are sorted, rinsed and crushed into a slurry, and then enter the Hanbo drying and chemical all-in-one machine (2 tons of volume), the mixing system starts to stir the materials, and the heating system starts to heat up. When the temperature of the material rises to 55°C, the heating system stops working, and the residual heat and the microorganisms in it work to generate heat to make the temperature of the material continue to rise. When the temperature of the material rises to about 60°C, the material outlet door of the all-in-one machine can be opened to allow The mixing system works to push the material from the middle to the door and then into the belt conveyor. The belt conveyor continues to convey the materials to the aging room, and the discharge time is 40-50 minutes. The material coming out enters the aging room, the aging room is 1.5 meters high, 2 meters wide, and 5 meters long. At this time, the temperature of the mater...

Embodiment 2

[0028] Step 1: The original kitchen materials are sorted, rinsed and crushed into a slurry, and then enter the Hanbo drying and chemical all-in-one machine (2 tons of volume), the mixing system starts to stir the materials, and the heating system starts to heat up. When the temperature of the material rises to 55°C, the heating system stops working, and the residual heat and the microorganisms in it work to generate heat to make the temperature of the material continue to rise. When the temperature of the material rises to about 60°C, the material outlet door of the all-in-one machine can be opened to allow The mixing system works to push the material from the middle to the door and then into the belt conveyor. The belt conveyor continues to convey the materials to the aging room, and the discharge time is 40-50 minutes. The material coming out enters the aging room, the aging room is 1.5 meters high, 2 meters wide, and 5 meters long. At this time, the temperature of the mater...

Embodiment 3

[0033]Step 1: The original kitchen materials are sorted, rinsed and crushed into a slurry, and then enter the Hanbo drying and chemical all-in-one machine (2 tons of volume), the mixing system starts to stir the materials, and the heating system starts to heat up. When the temperature of the material rises to 55°C, the heating system stops working, and the residual heat and the microorganisms in it work to generate heat to make the temperature of the material continue to rise. When the temperature of the material rises to about 60°C, the material outlet door of the all-in-one machine can be opened to allow The mixing system works to push the material from the middle to the door and then into the belt conveyor. The belt conveyor continues to convey the materials to the aging room, and the discharge time is 40-50 minutes. The material coming out enters the aging room, the aging room is 1.5 meters high, 2 meters wide, and 5 meters long. At this time, the temperature of the materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com