Anti-mosquito thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and anti-mosquito technology, applied in the field of polymer materials, can solve the problems of user injury, short mosquito repellent time, toxic and side effects, etc., and achieve the effect of improving the use effect, enhancing the volatilization effect, and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

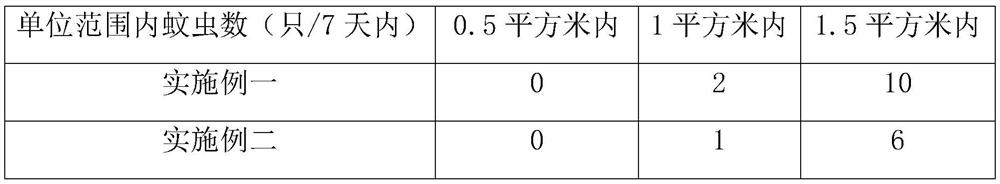

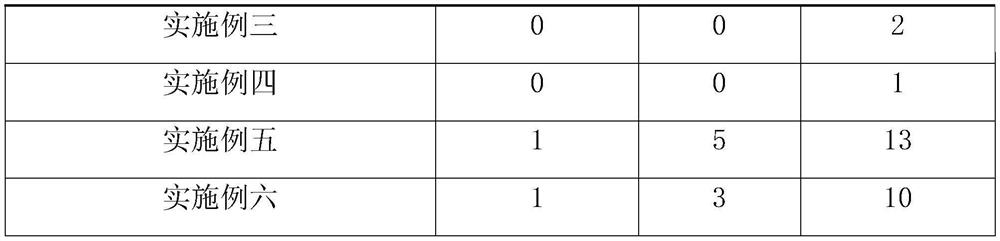

Examples

Embodiment 1

[0038] A kind of anti-mosquito thermoplastic elastomer, comprises following composition by weight ratio:

[0039] SEBS: 70 copies;

[0040] PE: 40 parts;

[0041] Methyl vinyl ether-maleic anhydride copolymer: 20 parts;

[0042] White wax oil: 15 parts;

[0043] Natural zeolite powder: 40 parts;

[0044] Mosquito repellent essential oil: 10 parts;

[0045] Antioxidant: 3 parts;

[0046] The mosquito repellent essential oil comprises the following components by weight:

[0047]Lemongrass essential oil, neem essential oil, lemon eucalyptus essential oil, white calamus essential oil, peppermint essential oil, 95% food grade ethanol with a mass ratio of 3:5:2:1:1:6: 9 parts;

[0048] Sodium alginate: 1 part;

[0049] Step 1: Weigh SEBS, PE, methyl vinyl ether-maleic anhydride copolymer, maleic anhydride-phthalic anhydride-diethylene glycol polymer and other additives and stir them fully in the mixer , the stirring time is 10 minutes, the temperature is raised to 50°C, and ...

Embodiment 2

[0054] A kind of anti-mosquito thermoplastic elastomer, comprises following composition by weight ratio:

[0055] SEBS: 70 copies;

[0056] PE: 40 copies;

[0057] Methyl vinyl ether-maleic anhydride copolymer: 20 parts;

[0058] White wax oil: 15 parts;

[0059] Natural zeolite powder: 40 parts;

[0060] Mosquito repellent essential oil: 15 parts;

[0061] Antioxidant: 3 parts;

[0062] The mosquito repellent essential oil comprises the following components by weight:

[0063] Lemongrass essential oil, neem essential oil, lemon eucalyptus essential oil, white calamus essential oil, peppermint essential oil, 95% food grade ethanol with a mass ratio of 3:5:2:1:1:6: 14 parts;

[0064] Sodium alginate: 1 part;

[0065] Step 1: Weigh SEBS, PE, methyl vinyl ether-maleic anhydride copolymer, maleic anhydride-phthalic anhydride-diethylene glycol polymer and other additives and stir them fully in the mixer , the stirring time is 10 minutes, the temperature is raised to 50°C, a...

Embodiment 3

[0070] A kind of anti-mosquito thermoplastic elastomer, comprises following composition by weight ratio:

[0071] SEBS: 70 copies;

[0072] PE: 40 copies;

[0073] Methyl vinyl ether-maleic anhydride copolymer: 20 parts;

[0074] White wax oil: 15 parts;

[0075] Natural zeolite powder: 40 parts;

[0076] Mosquito repellent essential oil: 20 parts;

[0077] Antioxidant: 3 parts;

[0078] The mosquito repellent essential oil comprises the following components by weight:

[0079] Lemongrass essential oil, neem essential oil, lemon eucalyptus essential oil, white calamus essential oil, peppermint essential oil, 95% food grade ethanol with a mass ratio of 3:5:2:1:1:6: 19 parts;

[0080] Sodium alginate: 1 part;

[0081] Step 1: Weigh SEBS, PE, methyl vinyl ether-maleic anhydride copolymer, maleic anhydride-phthalic anhydride-diethylene glycol polymer and other additives and stir them fully in the mixer , the stirring time is 10 minutes, the temperature is raised to 50°C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com