A kind of regeneration method of TSA tower in coke oven gas making lng device

A coke oven gas and tail gas technology, which is applied in the removal of gas pollutants, gas fuel, combustible gas purification, etc., can solve the problems of shortened life of adsorption packing, high power cost, accelerated deterioration, etc., and achieve efficient and harmless treatment , Improve the regeneration effect and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

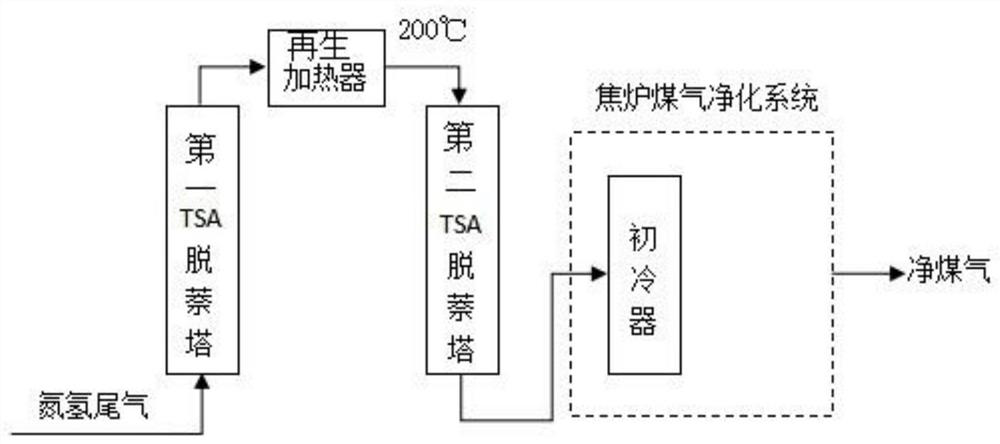

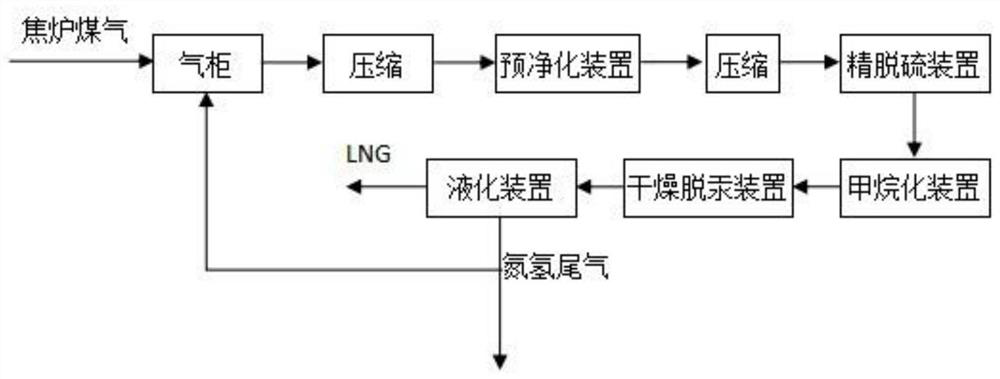

[0018] The present invention is described in further detail now in conjunction with accompanying drawing.

[0019] Such as Figure 1-2 , a regeneration method of a TSA tower in a coke oven gas LNG plant, comprising the following steps:

[0020] 1) Transport the coke oven gas to the gas holder for homogenization;

[0021] 2) Compressing the homogenized coke oven gas for the first time, and entering the pre-purification device for pretreatment, the pre-purification device includes a hydrogen sulfide removal unit and a temperature swing adsorption unit;

[0022] 3) The pretreated coke oven gas is compressed for the second time, and then enters the fine desulfurization device for fine desulfurization, in order to convert organic sulfur into hydrogen sulfide, and then desulfurize the hydrogen sulfide through a zinc oxide desulfurizer;

[0023] 4) transporting the finely stripped coke oven gas to a methanation unit, so that the coke oven gas is converted into a synthetic methane m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com