Wormwood plant antibacterial and antiviral fiber and preparation method thereof

A plant antibacterial and antiviral technology, applied in the direction of artificial filaments made of viscose, can solve the problems of high cost, low utilization rate of active ingredients, affecting the physical and mechanical properties of fibers, etc., to achieve acid and alkali stability, fiber Long-lasting antibacterial effect and good washing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

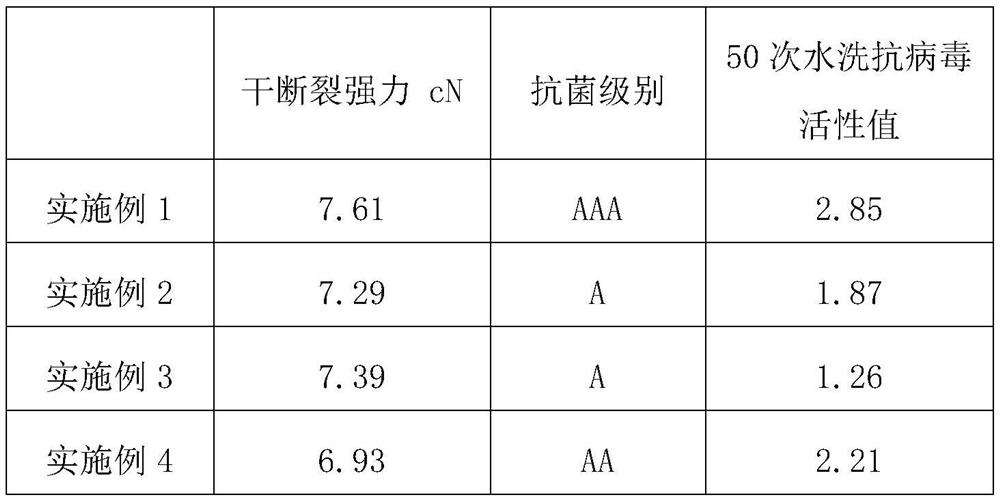

Examples

Embodiment 1

[0056] (1) After dissolving 40g of cucurbit [7] urea, add 120g of wormwood essential oil into a 250ml volumetric flask, shake at 25°C for 20min, then adjust the pH value to 2 with 1mol / L sulfuric acid, add twice distilled water to volume , preparing the clathrate of wormwood essential oil;

[0057] (2) The prepared wormwood essential oil clathrate is added in the acid bath, the addition is 12% of the quality of methyl cellulose in the viscose spinning stock solution, and mixed uniformly; the acid bath is composed of sulfuric acid 100g / L, sodium sulfate 300g / L, zinc sulfate 10g / L composition;

[0058] (3) urea is added in the viscose spinning stock solution, the addition amount is 2% of the methyl fiber content in the viscose spinning stock solution, after stirring evenly, spray into the acid bath and carry out spinning, make the wormwood plant antibacterial antibacterial viral fiber.

Embodiment 2

[0060] (1) After dissolving 40g cup of pyrrole, add 150g mugwort essential oil into a 250ml volumetric flask, shake at 25°C for 20min, then adjust the pH value to 1 with 1mol / L sulfuric acid, add double distilled water to make up the volume, and prepare mugwort Grass essential oil inclusion compound;

[0061] (2) The clathrate of wormwood essential oil prepared is added in the acid bath, the add-on is 5% of the methyl cellulose quality in the viscose spinning stock solution, mixes uniformly; The acid bath consists of sulfuric acid 100g / L, sodium sulfate 280g / L, composed of zinc sulfate 12g / L;

[0062] (3) KH-550 silane crosslinking agent is added in the viscose spinning stock solution, the addition amount is 5% of the methyl fiber content in the viscose spinning stock solution, after stirring evenly, spray into the acid bath and carry out spinning, make Get the antibacterial and antiviral fiber of wormwood plant.

Embodiment 3

[0064] (1) After dissolving 40g cup of carbazole, add 120g wormwood essential oil into a 250ml volumetric flask, shake at 25°C for 20min, then adjust the pH value to 4 with 1mol / L sulfuric acid, add twice distilled water to volume, and prepare Inclusion compound of wormwood essential oil;

[0065] (2) The clathrate of wormwood essential oil prepared is added in the acid bath, and the addition is 1% of the methyl cellulose quality in the viscose spinning stock solution, mixes uniformly; The acid bath is made of sulfuric acid 80g / L, sodium sulfate 330g / L, composed of zinc sulfate 9g / L;

[0066] (3) KH-792 silane cross-linking agent is added in the viscose spinning stock solution, the addition amount is 5% of the methyl fiber content in the viscose spinning stock solution, after stirring evenly, spray into the acid bath and carry out spinning, make Get the antibacterial and antiviral fiber of wormwood plant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com