Cellulose/calcium alginate blend fibers with skin-core structure and preparation method of cellulose/calcium alginate blend fibers

A technology of calcium alginate and skin-core structure, applied in cellulose/protein conjugated artificial filament, fiber treatment, filament/thread forming, etc. Problems such as cellulose burning, to achieve the effect of good flame retardant effect and good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

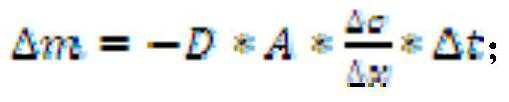

Method used

Image

Examples

Embodiment 1

[0056] A preparation method of a cellulose / alginic acid blended fiber, wherein the cellulose solution I is used as a skin layer component, and the cellulose / alginic acid blended solution is used as a core layer component, and after the skin-core composite spinning method is used for spinning, Enter the air section, the first coagulation bath (the ionic liquid aqueous solution with a mass concentration of 5%) and the second coagulation bath (the calcium chloride aqueous solution with a mass fraction of 1%), and then wash and dry to obtain cellulose / alginic acid blended fibers;

[0057] Wherein, the cellulose solution I is made by the cellulose that the degree of polymerization is 400 dissolved in the ionic liquid, and the cellulose / alginic acid blend solution is that the cellulose solution is mixed with the alginic acid solution to make, and the cellulose solution is made of the cellulose solution with a degree of polymerization of 300. Cellulose is dissolved in ionic liquid an...

Embodiment 2

[0065] A kind of preparation method of cellulose / alginic acid blended fiber, take cellulose solution I as skin layer component, cellulose / alginic acid blended solution as core layer component, after adopting sheath-core composite spinning method to carry out spinning, Enter the air section, the first coagulation bath (water) and the second coagulation bath (calcium chloride aqueous solution with a mass fraction of 1%) in sequence, and then wash and dry to obtain cellulose / alginic acid blended fibers;

[0066] Among them, the cellulose solution I is prepared by dissolving cellulose with a degree of polymerization of 500 in an ionic liquid, the cellulose / alginic acid blend solution is prepared by mixing a cellulose solution and an alginic acid solution, and the cellulose solution is prepared by Cellulose is dissolved in ionic liquid and made, and alginic acid solution is made by dissolving alginic acid in ionic liquid, and the viscosity ratio of cellulose solution and alginic aci...

Embodiment 3

[0069] A kind of preparation method of cellulose / alginic acid blended fiber, take cellulose solution I as skin layer component, cellulose / alginic acid blended solution as core layer component, after adopting sheath-core composite spinning method to carry out spinning, Enter the air section, the first coagulation bath (an ionic liquid aqueous solution with a mass concentration of 6%) and the second coagulation bath (a calcium chloride aqueous solution with a mass fraction of 2%) in sequence, and then wash and dry to obtain cellulose / alginic acid blended fibers;

[0070] Among them, the cellulose solution I is prepared by dissolving cellulose with a degree of polymerization of 600 in an ionic liquid, the cellulose / alginic acid blend solution is prepared by mixing a cellulose solution and an alginic acid solution, and the cellulose solution is prepared by Cellulose is dissolved in ionic liquid and made, and alginic acid solution is made by dissolving alginic acid in ionic liquid,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com