Recycled concrete with high compressive strength

A technology of recycled concrete and compressive strength, applied in the field of concrete, can solve the problems of reduced strength of recycled aggregates and reduced compressive strength of recycled concrete, and achieve the effects of improving stability, improving interface properties and promoting bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

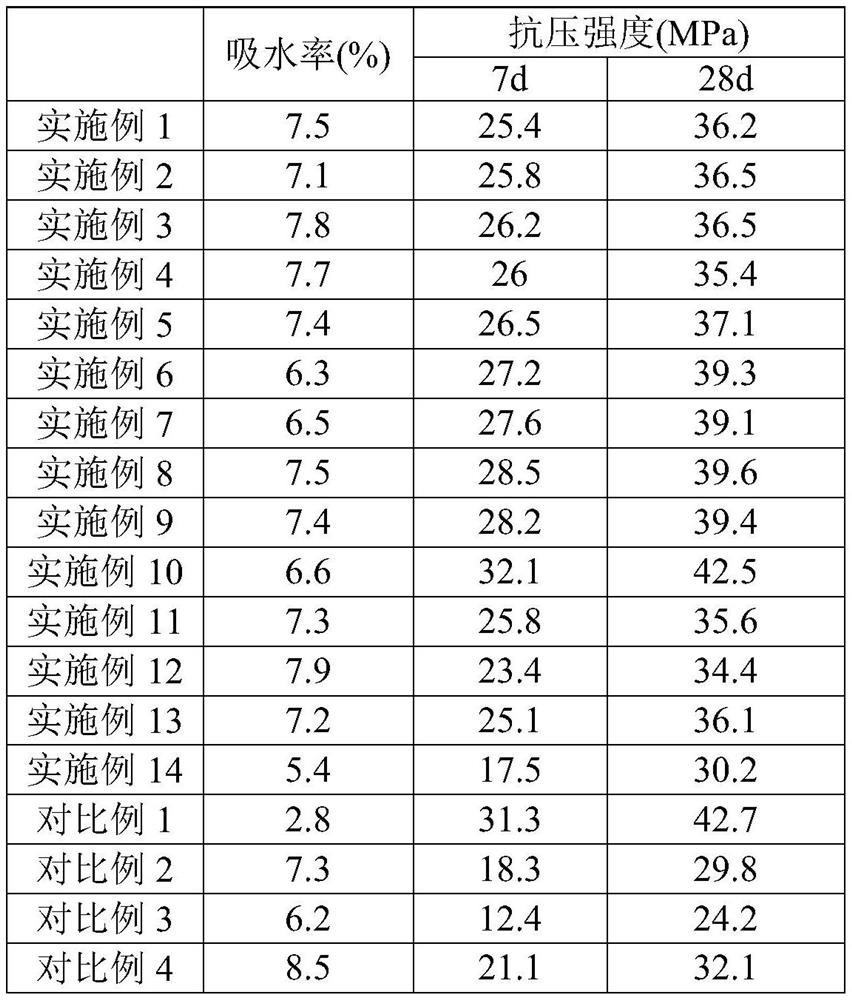

Examples

Embodiment 1

[0049] S1. Use a crusher to break the waste concrete into pieces, add the pieces to an ultrasonic cleaning machine, add water to immerse, ultrasonically clean for 1 hour, and sieve twice with a sieve to obtain recycled aggregates with a particle size of 5-9 mm.

[0050] S2. Add 100 kg of water, 85 kg of cement and 1 kg of green silicon carbide with a particle size of 400 mesh in the mixing tank, stir and disperse with a mixer for 15 minutes to obtain a cement slurry containing silicon carbide, add 50 kg of recycled aggregate to the cement slurry containing silicon carbide, Stir for 1 hour, then soak for 3 hours, then take out the recycled aggregate, filter out the cement slurry containing silicon carbide, dry the recycled aggregate in a 60°C oven for 1 hour, and use a sieve to remove the fallen solidified mortar to obtain silicon carbide strengthening treatment recycled aggregate.

[0051]S3. Add 15kg of silicon carbide reinforced recycled aggregate, 10kg of river sand, 0.05kg...

Embodiment 2 to Embodiment 5

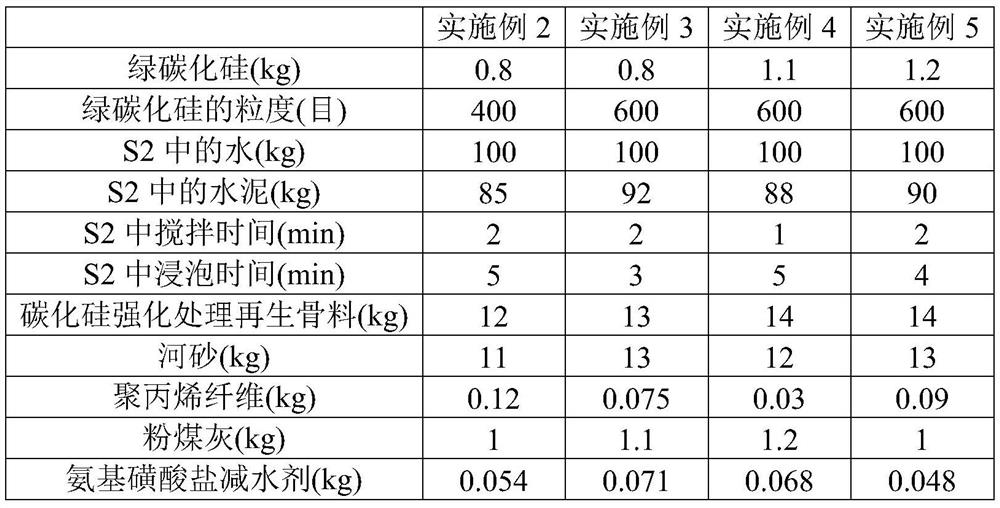

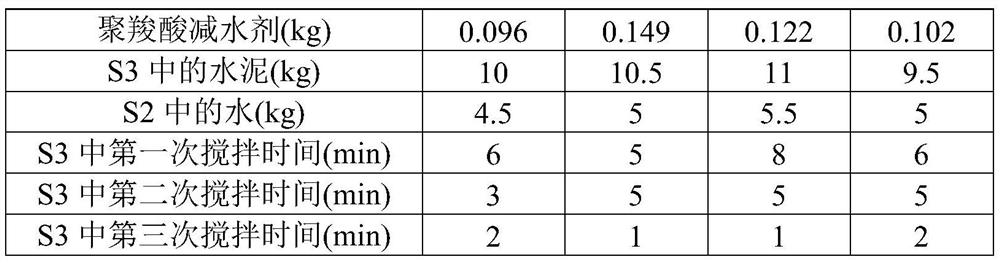

[0053] The difference between Example 2 to Example 5 and Example 1 lies in the differences in raw materials, raw material parameters and reaction time, as shown in Table 1.

[0054] Table 1

[0055]

[0056]

Embodiment 6

[0058] The only difference between this example and Example 5 is that in step S2, 0.15 kg of FN80 water-repellent agent is also added to the cement slurry containing silicon carbide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com