Low-concentration dimethylformamide wastewater recovery system and method

A technology for recycling dimethylformamide and wastewater, which is applied in the separation/purification of carboxylic acid amide, sustainable manufacturing/processing, chemical industry, etc., and can solve the secondary pollution of water phase, high investment and energy consumption, and recycled water Can not be reused and other problems, to achieve the effect of no secondary pollution, less investment in equipment, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

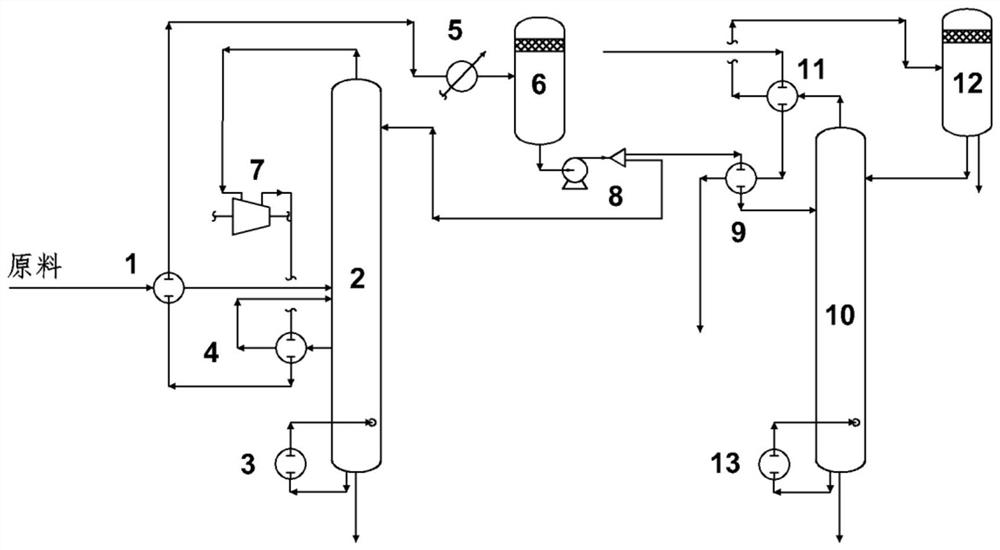

[0053] A low-concentration dimethylformamide wastewater recovery system, such as figure 1 as shown,

[0054] include:

[0055] Refining tower 2, impurity removing tower 10, raw material preheater 1 and feed preheater 9; refining tower 2 is provided with medium boiler 4, refining tower reboiler 3, compressor 7, refining tower condenser 5, refining Tower reflux tank 6 and reflux pump 8; the impurity removal tower 10 is provided with a reboiler 13 of the impurity removal tower, a condenser 11 of the impurity removal tower and a reflux tank 12 of the impurity removal tower;

[0056] The raw material inlet pipeline is connected to the refining tower 2 after the raw material preheater 1, and the outlet pipeline of the refining tower 2 is divided into two routes, one of which is connected to the refining tower reboiler 3 and then returns to the bottom of the refining tower 2, and the other part extracts the DMF product (DMF product mining The outgoing line is set in the refining to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com