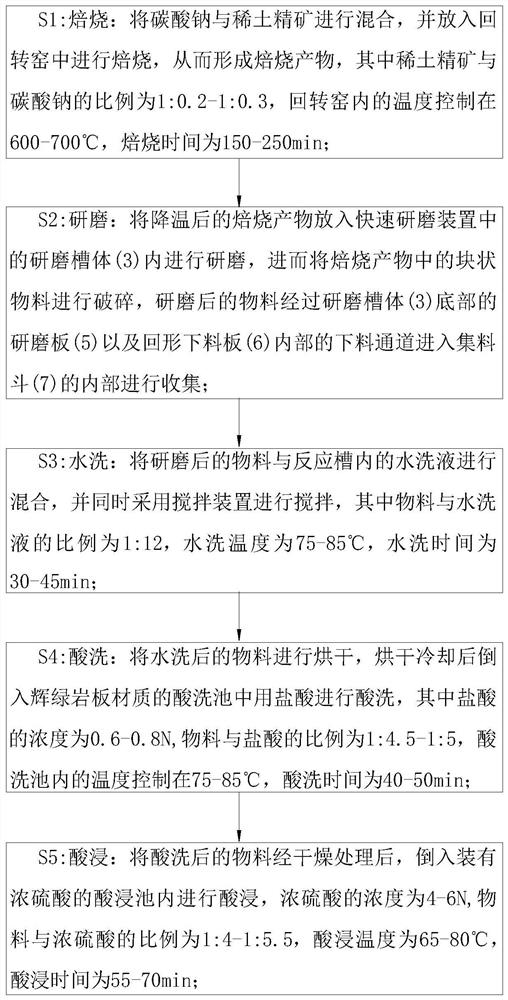

Rare earth concentrate treatment method

The invention relates to a technology of rare earth concentrate and a processing method, which is applied in the field of rare earth concentrate processing and can solve the problems of reducing the processing efficiency of rare earth concentrate, unreasonable sintering temperature and sintering time, and loss of rare earth concentrate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

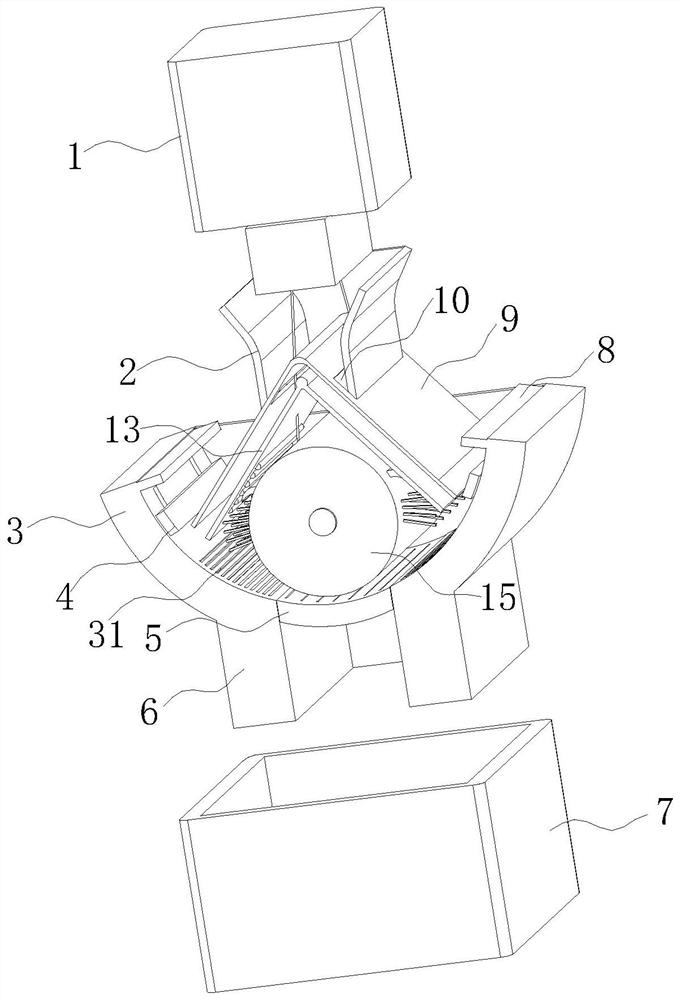

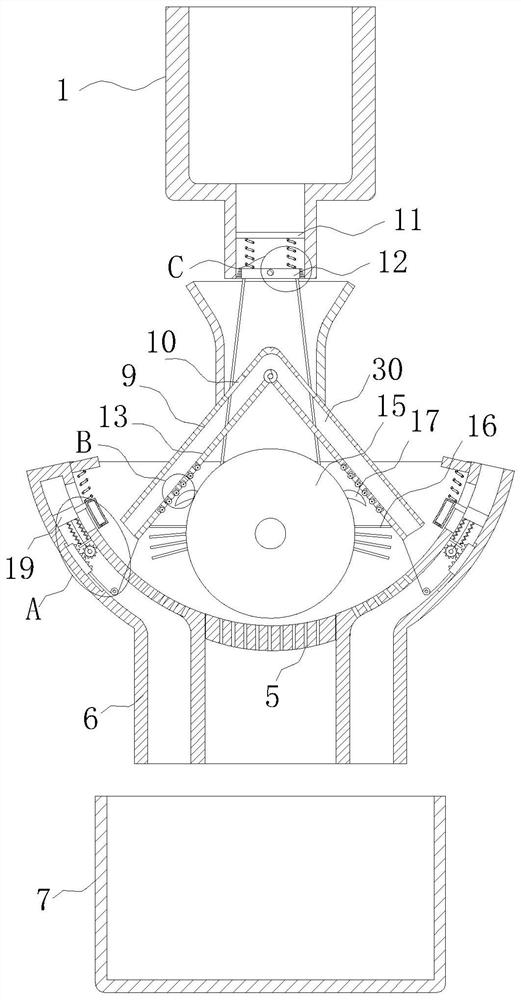

[0043] As an embodiment of the present invention, the top of the blanking plate 13 is articulated through a pin; the front and rear sides of the loading plate 9 and the blanking plate 13 are sealed and connected by an elastic rubber diaphragm 30; The two groups of inclined plates of the material plate 13 can rotate around the pin shaft; the edge of the grinding roller 15 is provided with an extruding rod 17 for moving the blanking plate 13 to the upper material plate 9; during work, the grinding roller 15 swings back and forth and While grinding the material on the grinding plate 5, the extrusion rod 17 positioned at the edge of the grinding roller 15 will intermittently beat the inner wall of the blanking plate 13, and then push the blanking plate 13 to the upper material plate 9, then the The large-grained material between the material plate 9 and the material plate 13 will be squeezed during the downward movement to achieve the effect of pre-crushing, thereby shortening the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com