Device and method for measuring surface contours of micro-nano devices based on optical frequency comb

A device surface and measurement device technology, applied in the direction of measurement devices, optical devices, instruments, etc., can solve the problems that cannot meet the measurement requirements of micro-nano devices, cannot cope with the characteristic size of micro-nano devices, and take a long time to measure. The effect of flux measurement requirements, fast measurement speed, and reduced requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

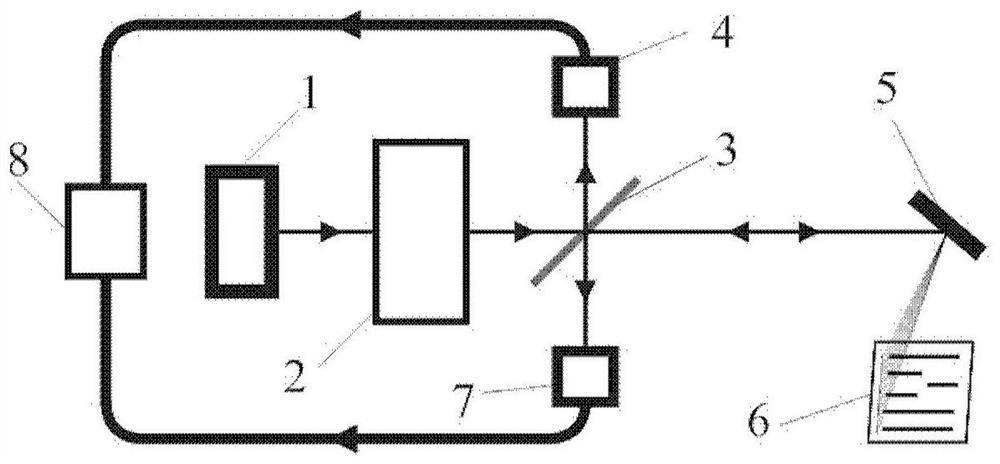

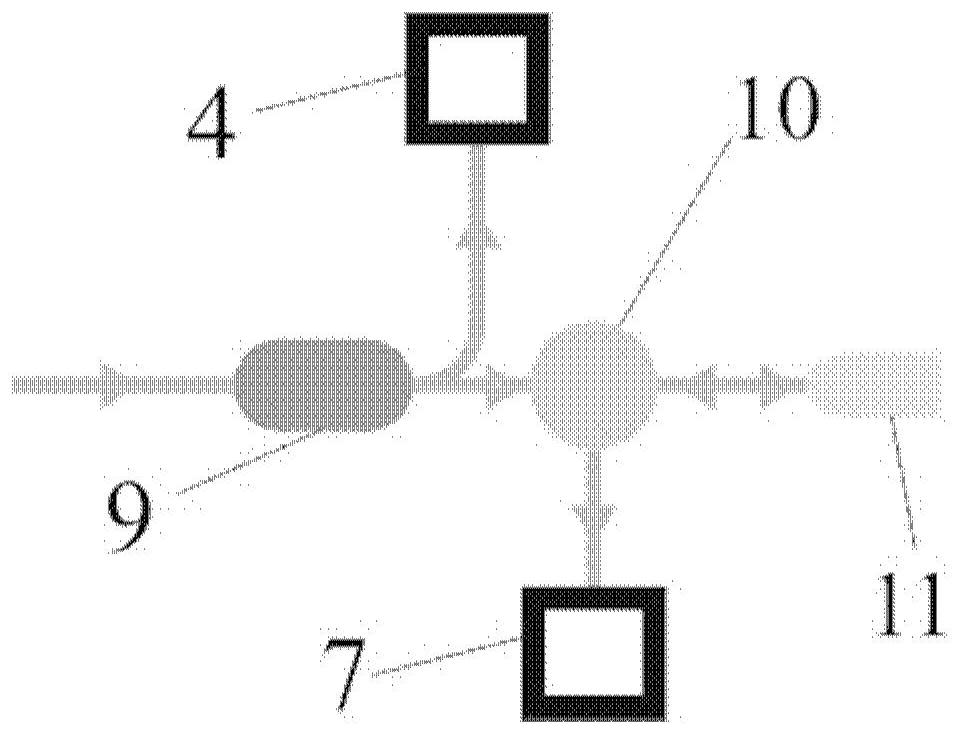

[0037] The invention uses a wide-spectrum optical frequency comb as a measurement light source, and divides a wide-spectrum pulse into a series of narrow-spectrum sub-pulses through processing. The series of sub-pulses have different spectral segments and are arranged at equal intervals in the time domain according to spectral components. Use the diffraction element to convert the spectral distribution into a spatial distribution. The sub-pulses at different spatial positions are reflected by the sample to be tested and return to the detector at different times. Using a single-pixel detector can complete multi-point measurement. According to the sub-pulse time-of-flight data can be Obtain 3D profile information. The device can be used to measure the surface contour of micro-nano devices, and is expected to provide a new detection method for the semiconductor field.

[0038] Specifically, the present invention discloses a device for measuring the surface contour of a micro-nano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com