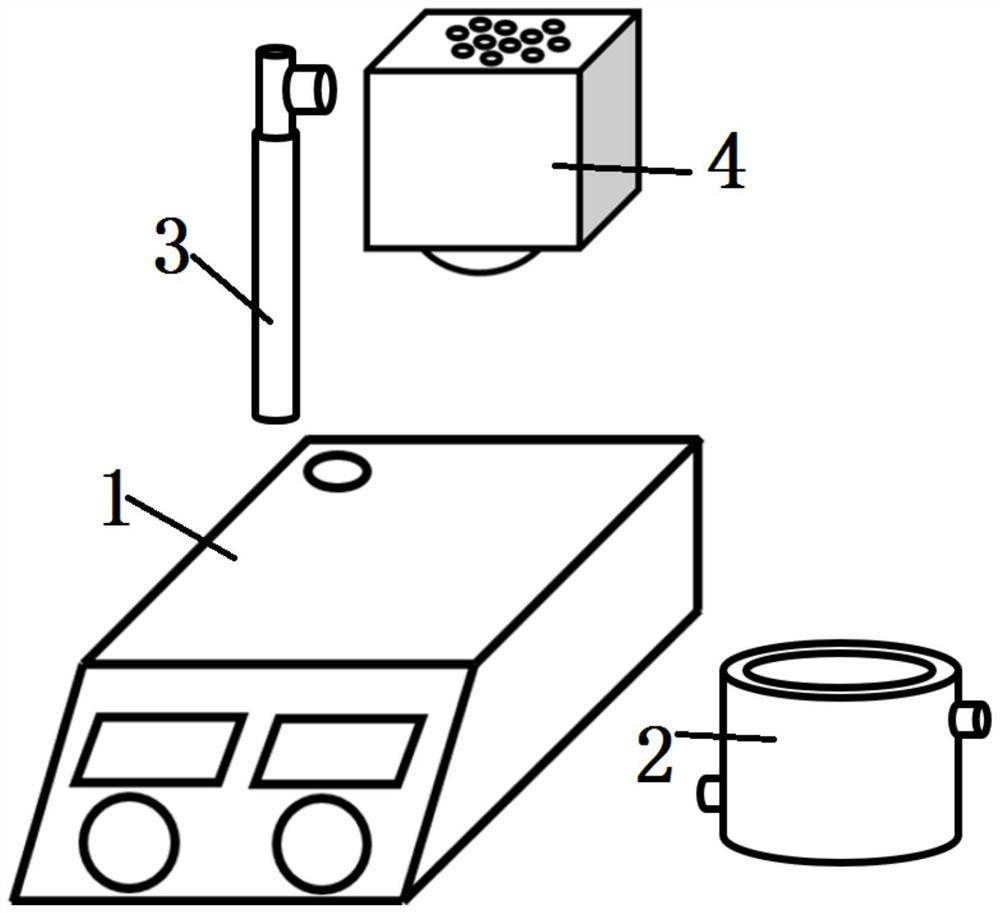

Integrated multifunctional photocatalysis experiment system

A technology of multifunctional catalysis and experimental system, applied in the field of integrated multifunctional photocatalytic experimental system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

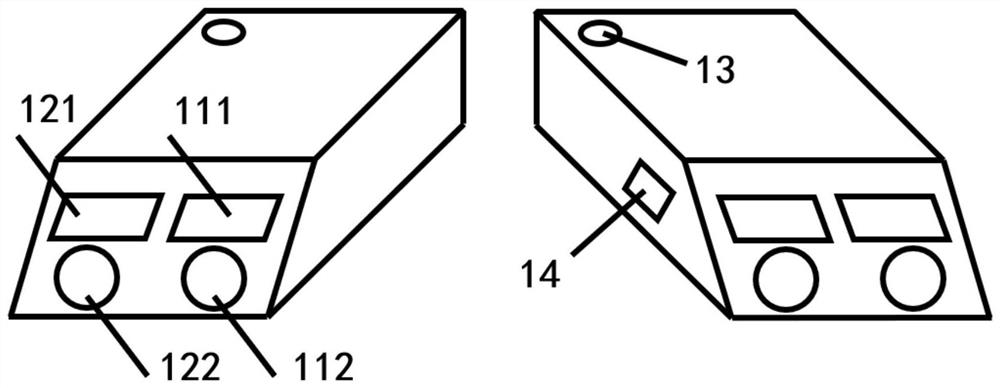

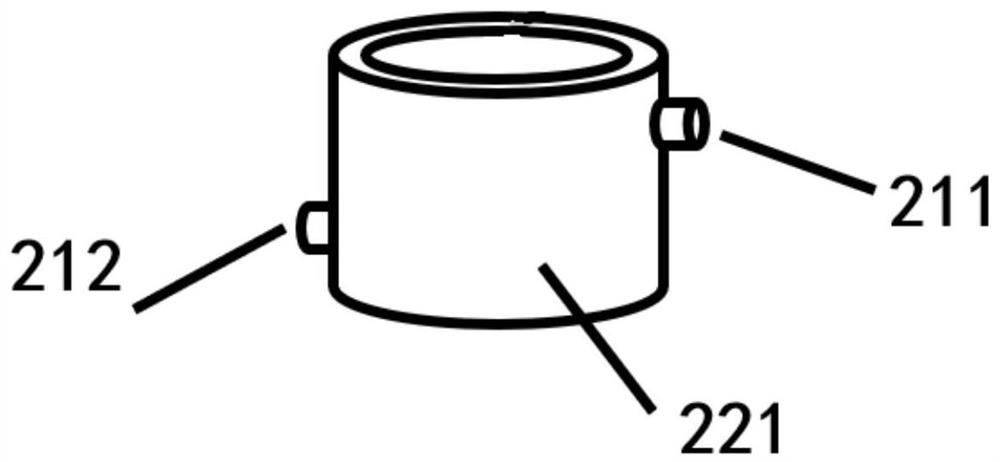

Method used

Image

Examples

Embodiment 1

[0062] Using UV-light, namely ultraviolet light:

[0063] In the experiment, put 50mg of bismuth oxychloride into the photocatalytic degradation reactor, then add 100mL rhodamine B simulated pollutant solution with a concentration of 20mg / L, and place it in a multifunctional integrated photocatalytic experiment designed by the present invention. On the magnetic stirrer of the system, stir at a speed of 500r / min for 2h, including dark reaction for 1h, using a 50W 365-370nm LED light source. During the reaction, the dark reaction is sampled every 30min, and the light reaction is sampled every 10min. 1.0 mL was sampled each time. After sampling, use a UV spectrophotometer to detect the degradation effect of Rhodamine B. For the specific effect, refer to Image 6 .

Embodiment 2

[0065] Using IR-light, namely infrared light:

[0066] In the experiment, put 50mg of chlorine oxidation into the photocatalytic degradation reactor, then add 100mL rhodamine B simulated pollutant solution with a concentration of 20mg / L, and place it in a multifunctional integrated photocatalytic experimental system designed by the present invention On a magnetic stirrer, stir at a speed of 500r / min for 2 hours, including dark reaction for 1 hour, using a 50W 850nm LED light source. During the reaction, the dark reaction is sampled every 30 minutes, and the light reaction is sampled every 10 minutes. 1.0mL. After sampling, use a UV spectrophotometer to detect the degradation effect of Rhodamine B. For the specific effect, refer to Image 6 .

Embodiment 3

[0068] Using Vis-light, both visible light

[0069] In the experiment, put 50mg of chlorine oxidation into the photocatalytic degradation reactor, then add 100mL rhodamine B simulated pollutant solution with a concentration of 20mg / L, and place it in a multifunctional integrated photocatalytic experimental system designed by the present invention On a magnetic stirrer, at a speed of 500r / min, stir for 2h, and dark reaction for 1h, choose 50W 410-420nm LED light source, during the reaction process, dark reaction is sampled every 30min, and light reaction is sampled every 10min. Sampling 1.0mL. After sampling, use a UV spectrophotometer to detect the degradation effect of Rhodamine B. For the specific effect, refer to Image 6 with Figure 7 In The new Device curve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com