Wave-edge rough milling cutter for machining cast iron scroll plate

A technology of scroll disk and rough milling cutter, which is applied in the direction of milling cutter, milling cutting blade, metal processing equipment, etc. It can solve the problems of chipping and damage of the cutting edge, affecting the life of the tool, and insufficient tool life, etc., to achieve light cutting, The effect of prolonging the service life and not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

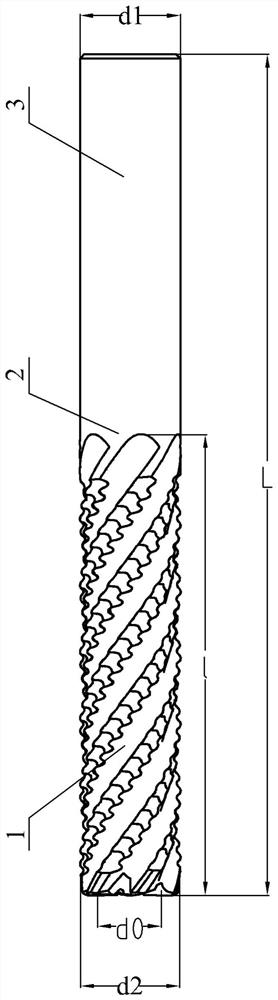

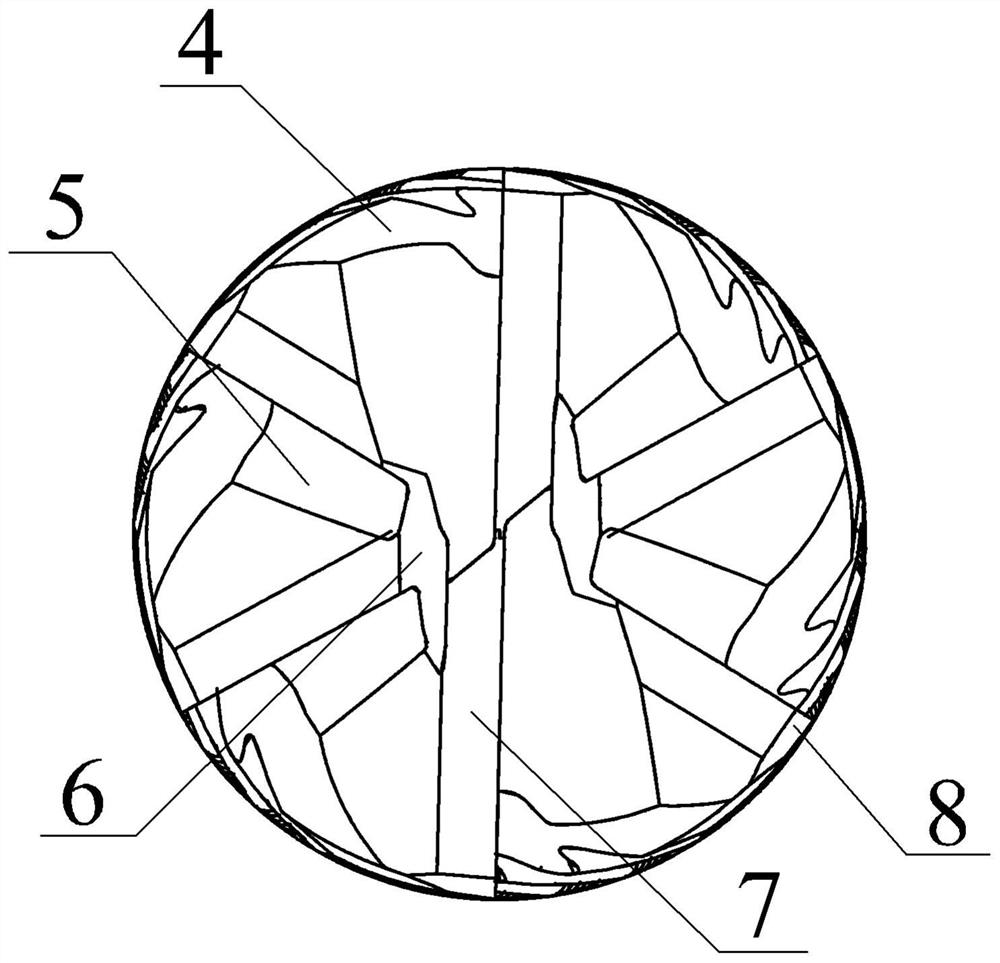

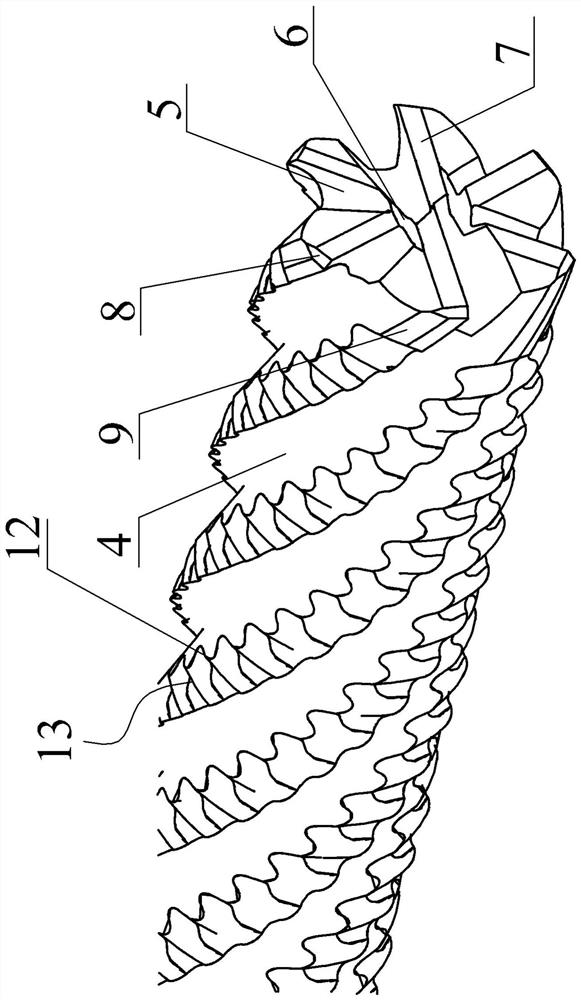

[0028] A wave edge rough milling cutter for machining cast iron scroll, see Figure 1-Figure 5 : including a tool holding handle 3, a cutting edge 1 and a transition neck 2, the transition neck 2 is used to connect the tool holding handle 3 and the cutting edge 1; the tool holding handle 3 is a cylindrical straight shank; the cutting The cutting edge 1 includes a number of cutting edges 13 and chip flutes 4 arranged in a spiral. In the cross-sectional state, N cutting edges 13 are arranged around the outer circumference of the cutting tool part 1, wherein N is a natural number greater than or equal to 3, and the arrangement The chip flute 4 is located in the corresponding interval area of the circumferential surface formed by the combination of adjacent cutting edges 13. The chip flute 4 includes a chip breaker 6 and a chip flute 5. The chip flute 5 is provided with a groove bottom surface and an outlet. On the knife face, each cutting edge 13 is composed of an end edge 7, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com