Manufacturing process of TPU-based high-performance automobile instrument panel

A technology of instrument panel and manufacturing process, which is applied in the field of manufacturing process of TPU-based high-performance automotive instrument panel, can solve the problems of large environmental pollution, low environmental protection, complicated operation, etc., and achieve flexible operation, high production efficiency and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

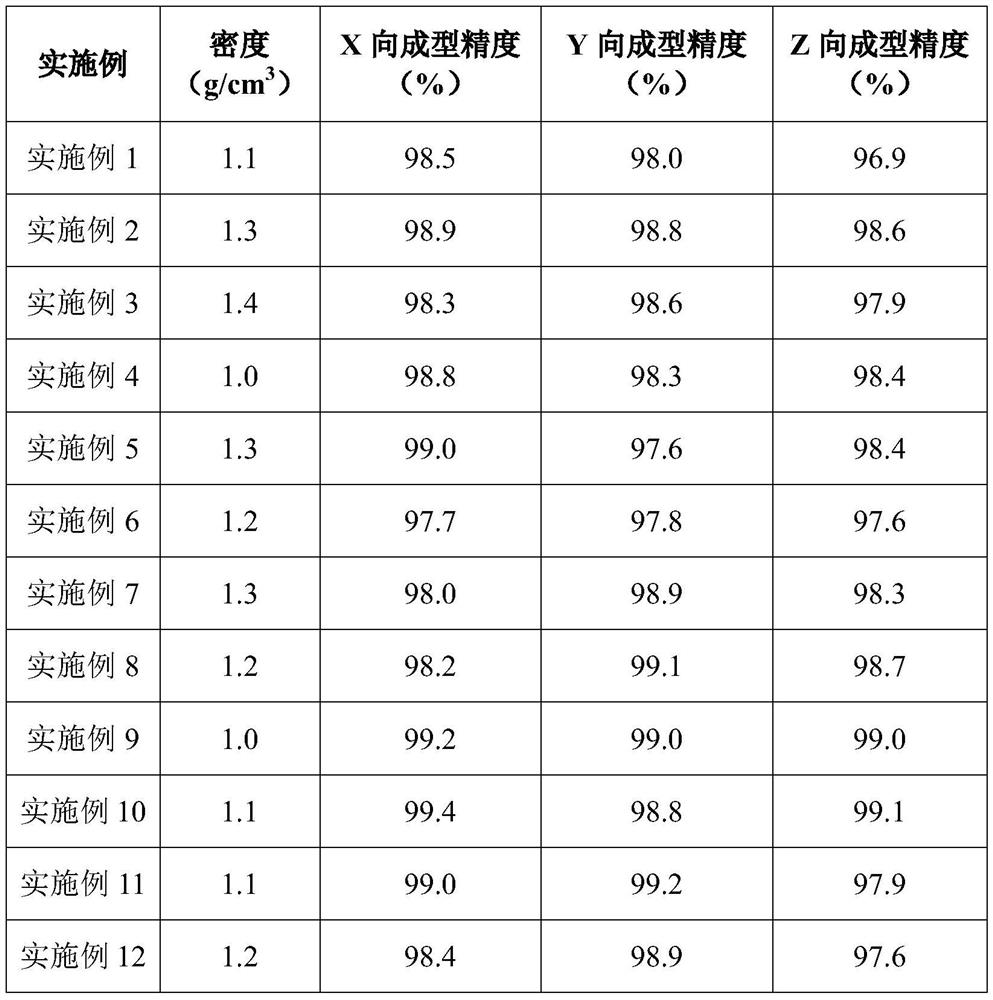

Examples

Embodiment 1

[0068] (1) 100 parts by mass of TPU powder, 10 parts by mass of impact-resistant filler, 10 parts by mass of anti-exposure filler, 5 parts by mass of nano-silica, 2 parts by mass of antioxidant, 1 part by mass of stabilizer, 10 parts by mass of talcum powder parts, 2 parts by mass of coupling agent, and 1 part by mass of weathering agent, put them into a high-speed mixer at 1200r / min, and mix for 15min.

[0069] (2) SLS molding standard splines, the molding process parameters are: printing temperature is set to 110°C, scanning speed is 6000mm / s, laser power is 25W, powder coating thickness is 0.10mm, and scanning distance is 0.08mm.

[0070] (3) Perform a performance test on the standard spline formed by SLS. Including mechanical performance test (impact strength test according to GB / T1043-93, spline tensile test according to GB / T1040-92), density test and precision test.

[0071] (4) SLS molding automobile instrument panel split, the molding process parameters are: printing ...

Embodiment 2

[0075] (1) 100 parts by mass of TPU powder, 10 parts by mass of impact-resistant filler, 10 parts by mass of anti-exposure filler, 5 parts by mass of nano-silica, 2 parts by mass of antioxidant, 1 part by mass of stabilizer, 10 parts by mass of talcum powder parts, 2 parts by mass of coupling agent, and 1 part by mass of weathering agent, put them into a high-speed mixer at 1200r / min, and mix for 15min.

[0076] (2) SLS molding standard spline, the molding process parameters are: printing temperature is set to 110°C, scanning speed is 7000mm / s, laser power is 25W, powder coating thickness is 0.10mm, and scanning distance is 0.10mm.

[0077] (3) Perform a performance test on the standard spline formed by SLS. Including mechanical performance test (impact strength test according to GB / T1043-93, spline tensile test according to GB / T1040-92), density test and precision test.

[0078] (4) SLS molding automobile instrument panel split, the molding process parameters are: printing t...

Embodiment 3

[0082] (1) 100 parts by mass of TPU powder, 10 parts by mass of impact-resistant filler, 10 parts by mass of anti-exposure filler, 5 parts by mass of nano-silica, 2 parts by mass of antioxidant, 1 part by mass of stabilizer, 10 parts by mass of talcum powder parts, 2 parts by mass of coupling agent, and 1 part by mass of weathering agent, put them into a high-speed mixer at 1200r / min, and mix for 15min.

[0083] (2) SLS molding standard splines, the molding process parameters are: printing temperature is set to 120°C, scanning speed is 7000mm / s, laser power is 35W, powder coating thickness is 0.15mm, and scanning distance is 0.30mm.

[0084] (3) Perform a performance test on the standard spline formed by SLS. Including mechanical performance test (impact strength test according to GB / T1043-93, spline tensile test according to GB / T1040-92), density test and precision test.

[0085] (4) SLS molding automobile instrument panel split, the molding process parameters are: printing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com