A kind of high-quality steel for forging bucket teeth and its preparation method

A high-quality technology for forging, used in manufacturing tools, metal rolling, metal rolling, etc., can solve problems such as difficulty in cutting raw materials, reduce the number and level, improve composition segregation, and shorten service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

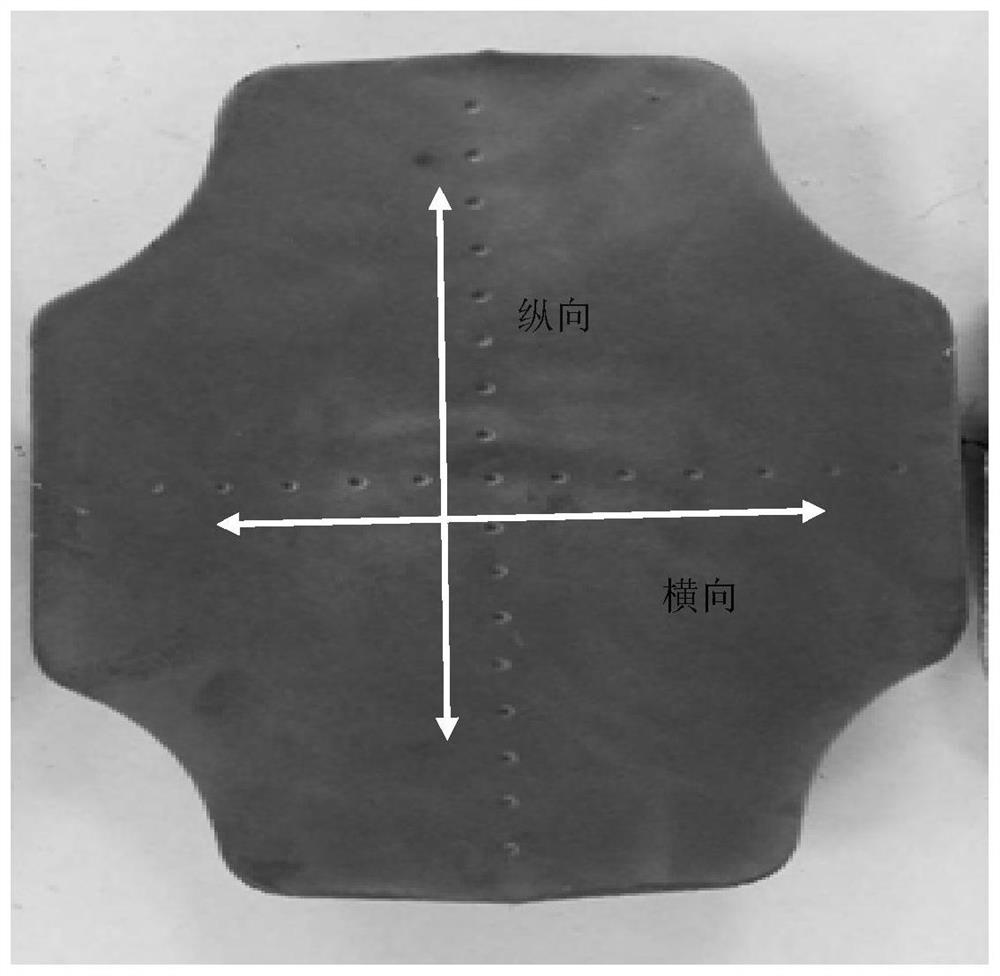

Image

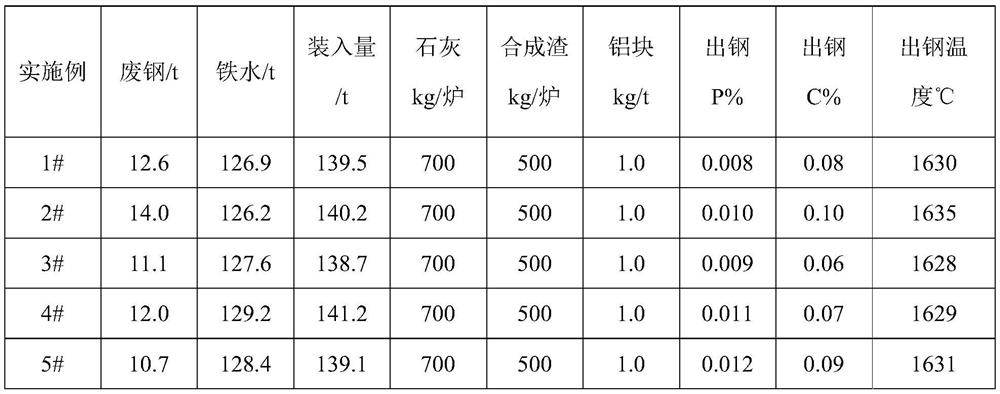

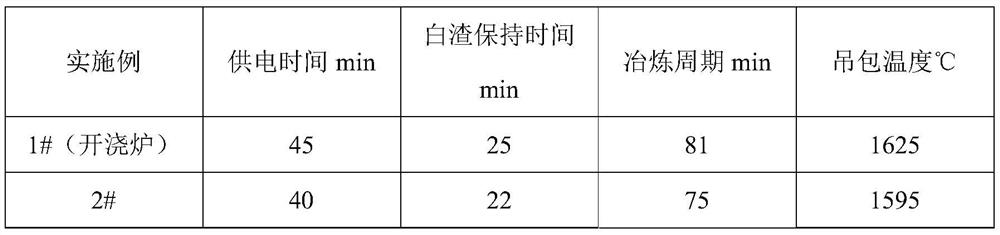

Examples

Embodiment 1

[0087] The surface hardness of the hot-rolled materials produced in Examples 1# to 5# is 280 to 330HBW. The hot-rolled materials within the hardness range can not only ensure the mechanical properties, but also solve the difficulty of blanking, serious wear of the saw blade, and poor sawing. Practical issues such as moving steel.

[0088] Processing the above-mentioned rolled material into a short ratio Standard sample blank, after heat treatment, the sample is prepared to measure the longitudinal mechanical properties of steel, heat treatment system: 900±15°C quenching (oil), holding time 50min, 200±10°C tempering (water, air), holding time 4 Hour.

[0089] The mechanical property of table 10 embodiment of the present invention

[0090]

[0091]

[0092]The optimized design of the components ensures better strength and toughness. Since the bucket teeth are in contact with high-hardness objects during the excavation process, the requirements for the impact toughness a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Charpy impact | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com