A kind of island-shaped Al thin film with Cu foil as substrate and its preparation method and application

A substrate and film technology, which is applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve the problems such as failure to meet the requirements for the use of negative electrodes of Li-ion battery materials, Al metal powder, and performance failure, etc. Achieving multiple reactive active sites, slowing down the speed of surface pulverization, and solving pulverization problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The method for preparing an island-shaped Al thin film with Cu foil as a substrate of the present invention comprises the following steps:

[0029] 1) Ultrasonic cleaning of the Cu foil substrate;

[0030] 2) drying the cleaned Cu foil substrate;

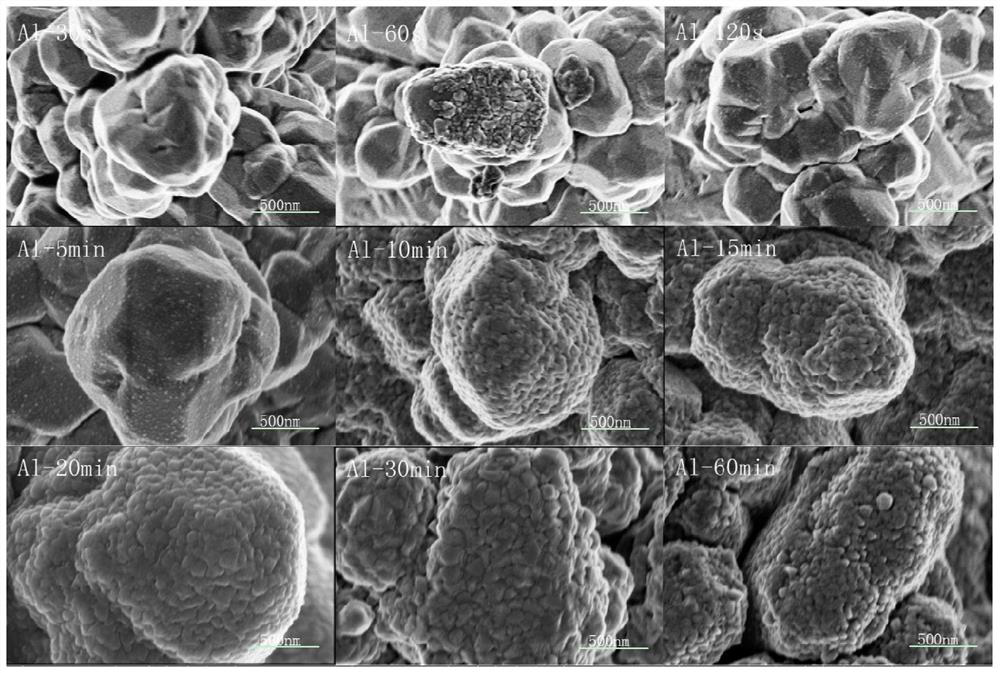

[0031] 3) Place the processed Cu foil substrate in the magnetron sputtering fixture, install the Al target on the target base, and adjust the target distance; the background vacuum is controlled at 10 -4 Pa, using argon to adjust the pressure of the sputtering chamber at 10 -3 ~10 -2 Within the range of Pa; adopt DC sputtering method to sputter to obtain Al monolayer film, and the sputtering time is 30s-5min, preferably 1-5min.

[0032] In step 1), the Cu foil substrate is ultrasonically cleaned for at least 10 min using absolute ethanol and deionized water in sequence.

[0033] In step 2), the cleaned Cu foil substrate is blown dry with high-purity argon to dry the solution on the surface.

[0034] In step 3), an Al tar...

Embodiment 1

[0038] The implementation process of the island-shaped Al thin film of the present invention comprises the following steps:

[0039] 1) Place the Cu foil substrate in anhydrous ethanol and deionized water in sequence to ultrasonically clean the substrate for 10 minutes;

[0040] 2) Drying the cleaned Cu foil substrate with high-purity nitrogen gas with a purity of 99.99%;

[0041] 3) Place the processed Cu foil substrate in the magnetron sputtering fixture, install the Al target on the target base, and adjust the target distance;

[0042] 4) The background vacuum of the sputtering chamber is at 10 -4 Pa, Cu foil substrate and Al target are first placed in the sampling chamber, and the sampling chamber is evacuated. When the pressure difference between the sputtering chamber and the sampling chamber is less than 10 times, the Cu foil substrate to be coated is fed into it; Adjust the gas pressure in the sputtering chamber at 10 -3 ~10 -2 Within the Pa range; adjust the rotat...

Embodiment 2

[0046] The implementation process of the island-shaped Al thin film of the present invention comprises the following steps:

[0047] 1) Place the Cu foil substrate in anhydrous ethanol and deionized water in sequence to ultrasonically clean the substrate for 10 minutes;

[0048] 2) Drying the cleaned Cu foil substrate with high-purity nitrogen gas with a purity of 99.99%;

[0049] 3) Place the processed Cu foil substrate in the magnetron sputtering fixture, install the Al target on the target base, and adjust the target distance;

[0050] 4) The background vacuum of the sputtering chamber is at 10 -4 Pa, Cu foil substrate and Al target are first placed in the sampling chamber, and the sampling chamber is evacuated. When the pressure difference between the sputtering chamber and the sampling chamber is less than 10 times, the Cu foil substrate to be coated is fed into it; Adjust the gas pressure in the sputtering chamber at 10 -3 ~10 -2 Within the Pa range; adjust the rotat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com