A microscopic pore model with variable surface wettability and methods for making and using the same

A microscopic model and microscopic pore technology, applied in the field of multiphase seepage, can solve the problems of narrow application range, high cost, complicated operation, etc., and achieve the effect of low cost, quick assembly and disassembly, and simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

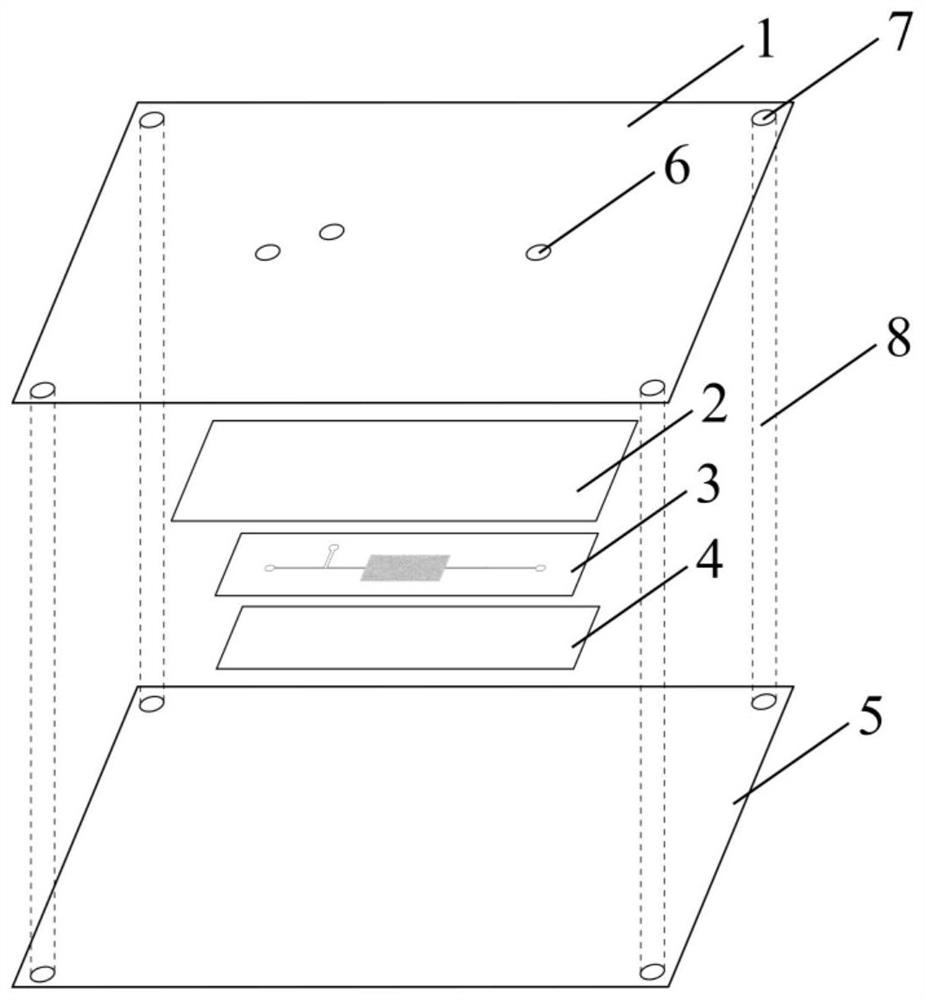

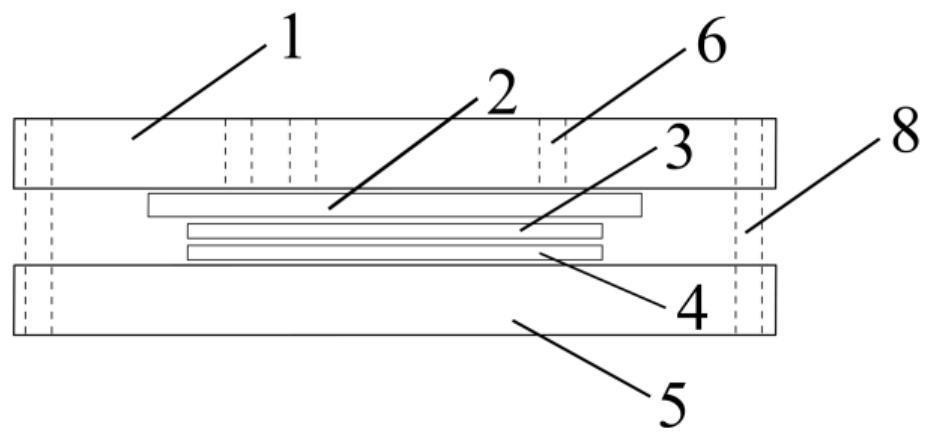

[0029] The present invention provides a microscopic pore model with variable surface wettability. The main structure is as follows: figure 1 As shown, it includes: an upper cover plate 1 , an upper cushion layer 2 , an upper pattern layer 3 of the microscopic model, a lower horizontal layer 4 of the microscopic model and a lower cover plate 5 .

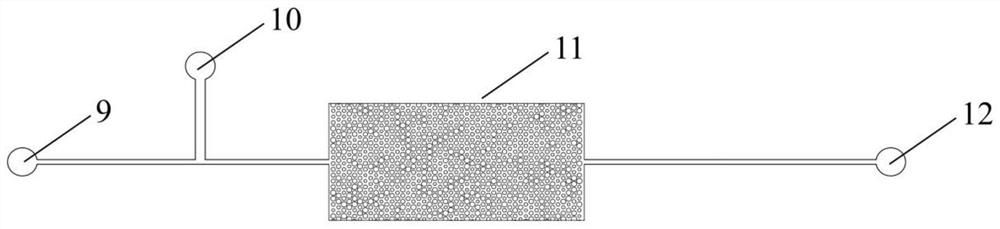

[0030] Among them, the shape of the upper cover plate 1 and the bottom cover plate 5 are both rectangular, the size is 85mm×60mm, the thickness is 4mm, the material is transparent plexiglass, the four corners are chiseled with a through hole 7 with a diameter of 3mm, and the screw 8 passes through it. The through hole 7 is used to fix the microscopic model as a whole; the upper cover plate 1 is engraved with three injection holes 6 with a diameter of 3mm, and the positions of the three injection holes 6 are respectively connected with the water phase injection hole 9 of the pattern layer 3 on the upper part of the microscopic model. T...

Embodiment 2

[0034] A method for making a microscopic pore model with variable surface wettability provided by the present invention specifically comprises the following steps:

[0035] (1) Mold making: use MATLAB software to generate CAD drawings of the required patterns, and process the mask plate according to the CAD drawings; select a 4-inch single-crystal silicon wafer with a flat and clean surface, and spin coat a layer of thickness on the surface of the silicon wafer with a coating machine 40μm SU8-2035 photoresist, the rotation speed is 3300 rpm; after the coating is finished, place the silicon wafer coated with photoresist on the hot stage and bake it at 65°C for 3 minutes, then bake it at 95°C for 6 minutes Take it off; after the baking is completed, use a mask plate to perform UV exposure under the photolithography machine for 16s. Next; then soak the silicon wafer in the SU8-2035 photoresist developer for 5 minutes, take it out and rinse it repeatedly with isopropanol and alcoh...

Embodiment 3

[0040] The invention provides a method for using a microscopic pore model with variable surface wettability, which specifically includes the following steps:

[0041] (1) Connect the injection holes (9, 10, 12) of the microscopic model with the pipeline, the pipeline of the buffer hole 10 is connected with the waste liquid container, and the pipelines of the injection holes (9, 12) at both ends are connected with the micro syringe, and the microscopic Place the syringe on the high-precision syringe pump; inhale appropriate amount of silicone oil and deionized water into the high-precision syringe pump, and inject high-viscosity silicone oil (viscosity 1000cs) from the oil phase injection hole 12 at a relatively low rate (such as 0.01μL / min) , close the syringe pump when the silicone oil flows out from the buffer hole 10;

[0042] (2) Inject dyed deionized water from the water phase injection hole 9 according to the experimental setting rate (such as 0.5 μ L / min), and stop inje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com