Method for repairing performance of oxidative damage protein gel based on PP-TGase

A technology of oxidative damage and protein gel, applied in the direction of peptide preparation methods, chemical instruments and methods, fibrinogen, etc., to achieve the effect of reducing the content of α-helix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

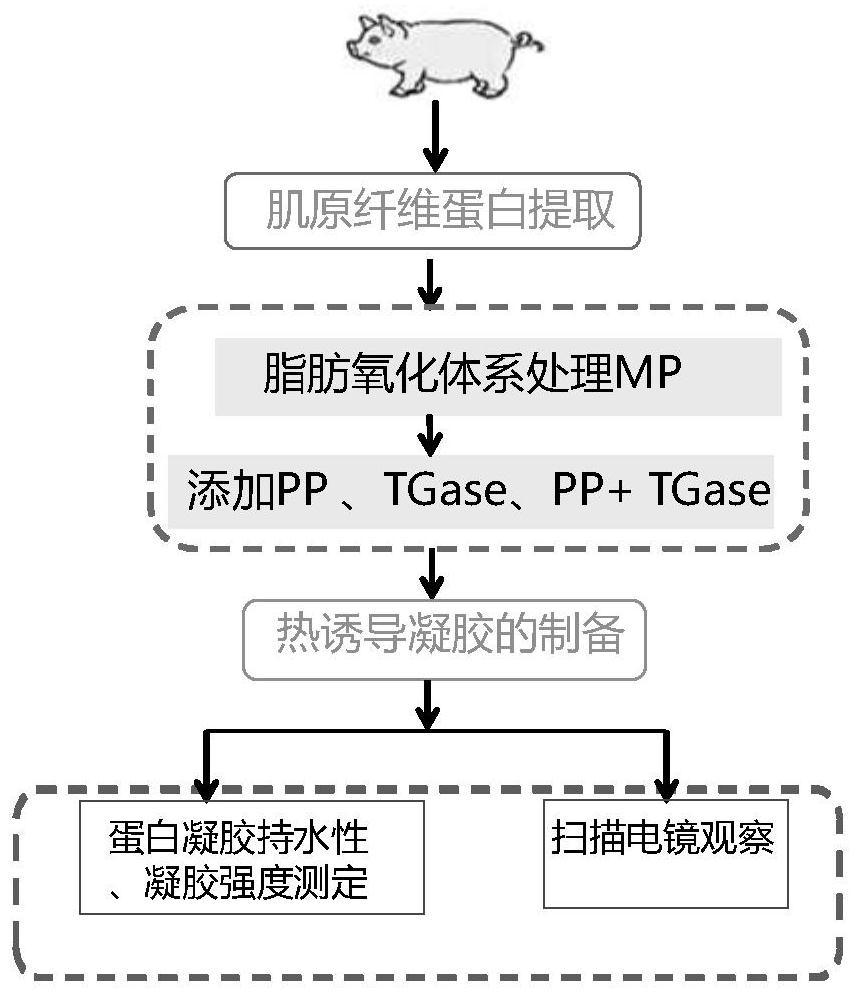

Method used

Image

Examples

Embodiment 1

[0077] This embodiment 1 provides a method for repairing the gel properties of oxidatively damaged proteins based on PP, comprising the following steps:

[0078] Step 1. Extract pork myofibrillar protein at 0-4°C to prepare myofibrillar protein paste; the preparation process specifically includes the following steps:

[0079] Step 11, cut into strips; remove fat and connective tissue from the pork tenderloin, cut into strips and weigh them for later use.

[0080] Step 12. Separation; place the processed strips of tenderloin in a tissue masher, add four times the volume of stiff liquid, homogenate and mash, and then centrifuge to obtain the primary sediment; add four times the volume to the primary sediment volume of stiff liquid, repeated homogenization and crushing, and centrifuged 3-4 times to obtain a precipitate; wherein, the concentration of NaCl in the stiff liquid was 0.1-0.15mol / L, MgCl 2 The concentration is 2-3mmol / L, Na 2 HPO 4The concentration of EGTA is 10-11mm...

Embodiment 2

[0092] This embodiment 2 provides a method for repairing the gel properties of oxidatively damaged proteins based on TGase, comprising the following steps:

[0093] Step 1. Extract pork myofibrillar protein at 0-4°C to prepare myofibrillar protein paste; the preparation process specifically includes the following steps:

[0094] Step 11, cut into strips; remove fat and connective tissue from the pork tenderloin, cut into strips and weigh them for later use.

[0095] Step 12. Separation; place the processed strips of tenderloin in a tissue masher, add four times the volume of stiff liquid, homogenate and mash, and then centrifuge to obtain the primary sediment; add four times the volume to the primary sediment volume of stiff liquid, repeated homogenization and crushing, and centrifuged 3-4 times to obtain a precipitate; wherein, the concentration of NaCl in the stiff liquid was 0.1-0.15mol / L, MgCl 2 The concentration is 2-3mmol / L, Na 2 HPO 4 The concentration of EGTA is 10-...

Embodiment 3

[0107] This embodiment 3 provides a method for repairing the gel performance of oxidatively damaged proteins based on PP-TGase, comprising the following steps:

[0108] Step 1. Extract pork myofibrillar protein at 0-4°C to prepare myofibrillar protein paste; the preparation process specifically includes the following steps:

[0109] Step 11, cut into strips; remove fat and connective tissue from the pork tenderloin, cut into strips and weigh them for later use.

[0110] Step 12. Separation; place the processed strips of tenderloin in a tissue masher, add four times the volume of stiff liquid, homogenate and mash, and then centrifuge to obtain the primary sediment; add four times the volume to the primary sediment volume of stiff liquid, repeated homogenization and crushing, and centrifuged 3-4 times to obtain a precipitate; wherein, the concentration of NaCl in the stiff liquid was 0.1-0.15mol / L, MgCl 2 The concentration is 2-3mmol / L, Na 2 HPO 4 The concentration of EGTA is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com