A method for preparing high-temperature and high-pressure gas and its application

A high-temperature and high-pressure gas and high-pressure technology, which is applied in chemical instruments and methods, chemical/physical/physical-chemical processes, chemical/physical processes, etc., can solve the problems of low operating cost, pure gas preparation, long-term gas supply and low cost, etc. problem, to achieve the effect of low price, easy handling and transportation, and improvement of spatial uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

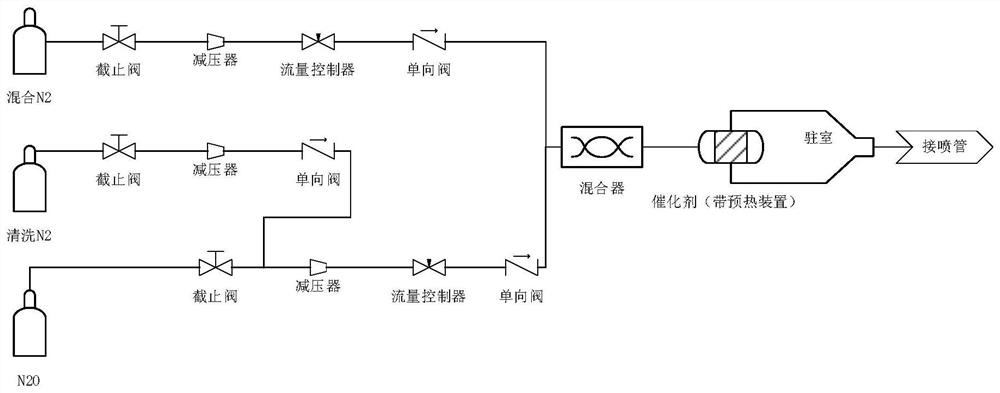

[0041] figure 1 It shows a system that adopts the catalytic decomposition of nitrous oxide to generate high-temperature and high-pressure gas for aerodynamic tests, and its main components are as follows figure 1 As shown in , including mixed nitrogen branch, cleaning nitrogen branch, nitrous oxide branch, mixer, catalytic reaction heating chamber and resident chamber; nitrogen branch includes nitrogen storage bottle, shut-off valve, pressure reducing valve, flow control and one-way valve; cleaning nitrogen branch includes nitrogen storage bottle, stop valve, pressure reducing valve and one-way valve; nitrous oxide branch includes nitrous oxide storage bottle, stop valve, pressure reducing valve and flow controller and check valve. The cleaning nitrogen branch and the nitrous oxide branch converge after the cut-off valve of the nitrous oxide branch, and the three branches converge at the mixer in front of the catalytic reaction heating chamber.

[0042] All valves are closed...

Embodiment 2

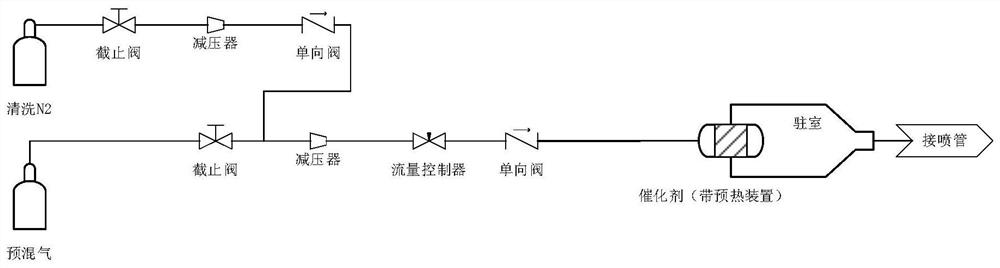

[0046] figure 2 It shows a system that uses nitrous oxide and nitrogen premixed gas to produce high-temperature and high-pressure gas for aerodynamic tests through catalytic decomposition. Its main components are as follows figure 2 As shown, including nitrous oxide and nitrogen premixed gas branch, purge nitrogen gas branch, catalytic reaction heating chamber and resident chamber; nitrous oxide and nitrogen premixed gas branch includes nitrous oxide and nitrogen premixed gas Storage bottle, shut-off valve, pressure reducing valve, flow controller and one-way valve; cleaning nitrogen branch includes nitrogen storage bottle, shut-off valve, pressure reducing valve and one-way valve. The purge nitrogen branch and the nitrous oxide and nitrogen premix branch converge after the shut-off valve of the nitrous oxide and nitrogen premix branch.

[0047] The ratio of nitrous oxide to nitrogen premixed gas is about 1:0.88 by molar ratio, order according to the ratio.

[0048] All va...

Embodiment 3

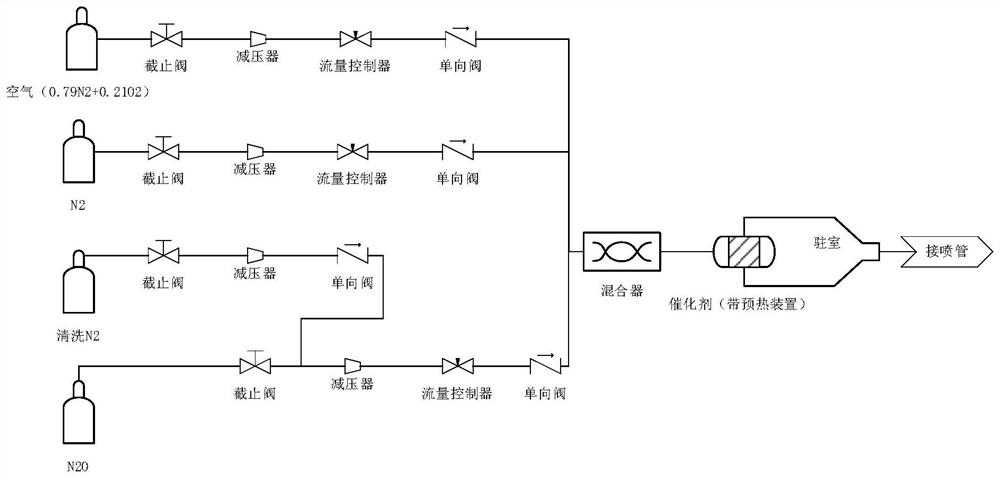

[0052] image 3 It shows a system that uses nitrous oxide, nitrogen and air mixed to produce high-temperature and high-pressure gas for aerodynamic tests through catalytic decomposition. Its main components are as follows image 3 As shown, it includes nitrous oxide branch circuit, nitrogen gas branch circuit, air branch circuit, cleaning nitrogen gas branch circuit, mixer, catalytic reaction heating chamber and resident chamber; the nitrous oxide branch circuit includes nitrous oxide storage bottle, cut-off valve, pressure reducing valve, flow controller and one-way valve; nitrogen branch includes nitrogen storage bottle, stop valve, pressure reducing valve, flow controller and one-way valve; air branch includes air storage bottle, stop valve, pressure reducing valves, flow controllers and check valves; the purge nitrogen branch includes nitrogen storage cylinders, shut-off valves, pressure reducing valves and check valves. The cleaning nitrogen branch and the nitrous oxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com