Hot continuous rolling production control method in constant-gap organizing mode

A production control method, hot continuous rolling technology, applied in the direction of rolling mill control device, metal rolling, metal rolling, etc., can solve the problems of increased running time, no rolling line rhythm control, etc., to avoid scrap steel and accidents, production high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

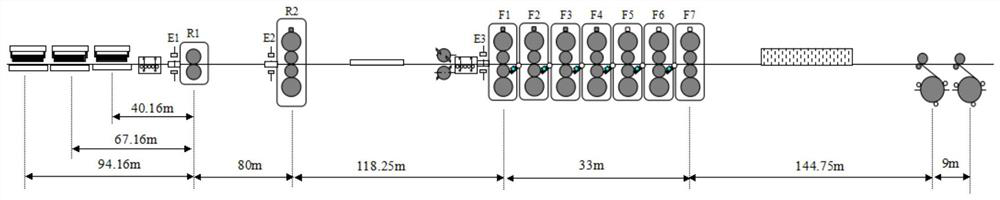

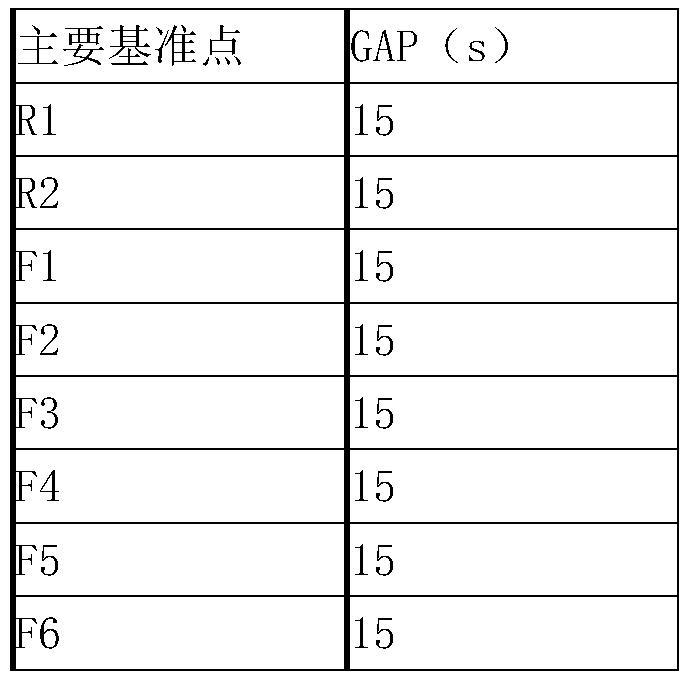

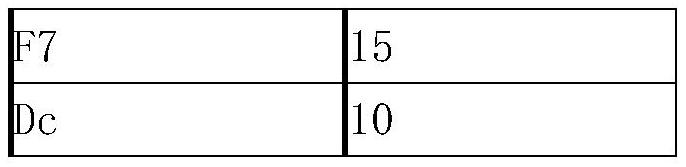

[0031] Example 1: 2 roughing mills in the 1780 production line, 3 passes each in R1 and R2, 7 finishing mills, and 2 coilers. The main equipment distance is as figure 1 Shown:

[0032] At a certain moment, this piece of steel is in the 1# furnace with a rolling specification of 3.45*1265, and the next piece of steel is in the 2# furnace with a rolling specification of 5.01*1300. The production method of constant gap tissue is as follows:

[0033]1) Determine the reference points of the main process equipment, heating furnace, R1 rolling mill, R2 rolling mill, F1, F2, F3, F4, F5, F6, F7 rolling mill, DC1 coiler pinch roll, the distance between the heating furnace and the R1 rolling mill, R1 Rolling mill to R2 rolling mill, R2 rolling mill to R3 rolling mill---Rb rolling mill to F1 rolling mill, F1 rolling mill to 1# coiler pinch roll spacing are 401600 / 671600 / 941600 (corresponding to 1# furnace, 2# furnace and 3 #furnace), 80000, 1182500, 5500, 5500, 5500, 5500, 5500, 5500, ...

Embodiment 2

[0059] Example 2: The 1780 production line has 2 roughing mills, R1 and R2 each rolled for 3 passes, 7 finishing mills, and 2 coilers. The main equipment distance is as figure 1 Shown:

[0060] At a certain moment, this piece of steel is in the 2# furnace with a rolling specification of 5.01*1300, and the next piece of steel is in the 3# furnace with a rolling specification of 7.07*1040. The production method of constant gap tissue is as follows:

[0061] 1) Determine the reference points of the main process equipment, heating furnace, R1 rolling mill, R2 rolling mill, F1, F2, F3, F4, F5, F6, F7 rolling mill, DC1 coiler pinch roll, the distance between the heating furnace and the R1 rolling mill, R1 Rolling mill to R2 rolling mill, R2 rolling mill to R3 rolling mill---Rb rolling mill to F1 rolling mill, F1 rolling mill to 1# coiler pinch roll spacing are 401600 / 671600 / 941600 (corresponding to 1# furnace, 2# furnace and 3 #furnace), 80000, 1182500, 5500, 5500, 5500, 5500, 55...

Embodiment 3

[0087] Example 3: 2 roughing mills in the 1780 production line, 3 passes each in R1 and R2, 7 finishing mills, and 2 coilers. The main equipment distance is as figure 1 Shown:

[0088] At a certain moment, this piece of steel is in the 3# furnace with a rolling specification of 7.07*1040, and the next piece of steel is in the 1# furnace with a rolling specification of 2.0*1214. The production method of constant gap tissue is as follows:

[0089] 1) Determine the reference points of the main process equipment, heating furnace, R1 rolling mill, R2 rolling mill, F1, F2, F3, F4, F5, F6, F7 rolling mill, DC1 coiler pinch roll, the distance between the heating furnace and the R1 rolling mill, R1 Rolling mill to R2 rolling mill, R2 rolling mill to R3 rolling mill---Rb rolling mill to F1 rolling mill, F1 rolling mill to 1# coiler pinch roll spacing are 401600 / 671600 / 941600 (corresponding to 1# furnace, 2# furnace and 3 #furnace), 80000, 1182500, 5500, 5500, 5500, 5500, 5500, 5500, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com