Ultrasonic-resistance hybrid welding method for resin-based composite material

A composite material and welding method technology, which is applied in the field of composite material connection, can solve problems such as the inability to achieve effective welding of resin-based composite materials, and achieve the effects of simple and fast implementation process, wide application prospects, and efficient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An ultrasonic-resistance hybrid welding method for resin-based composite materials, the specific operation steps are as follows:

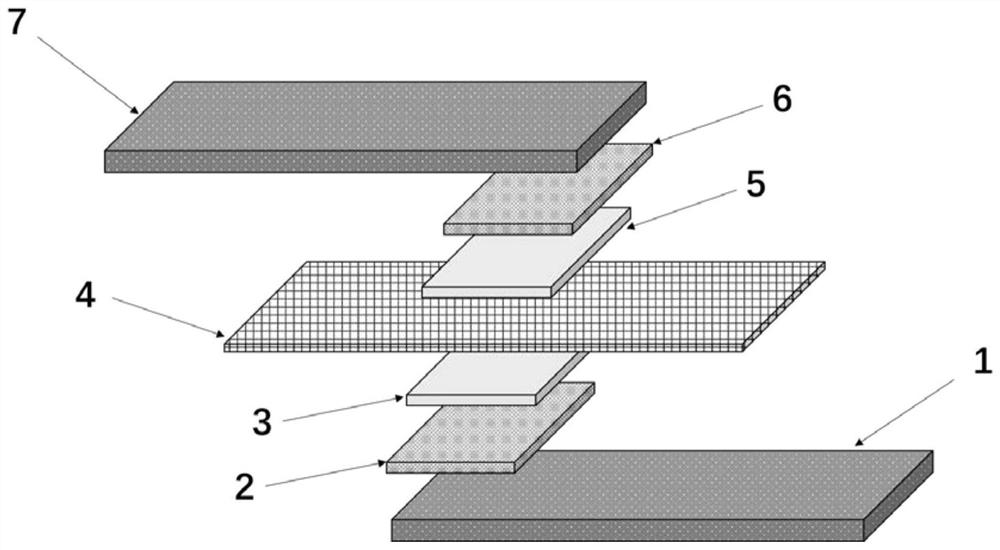

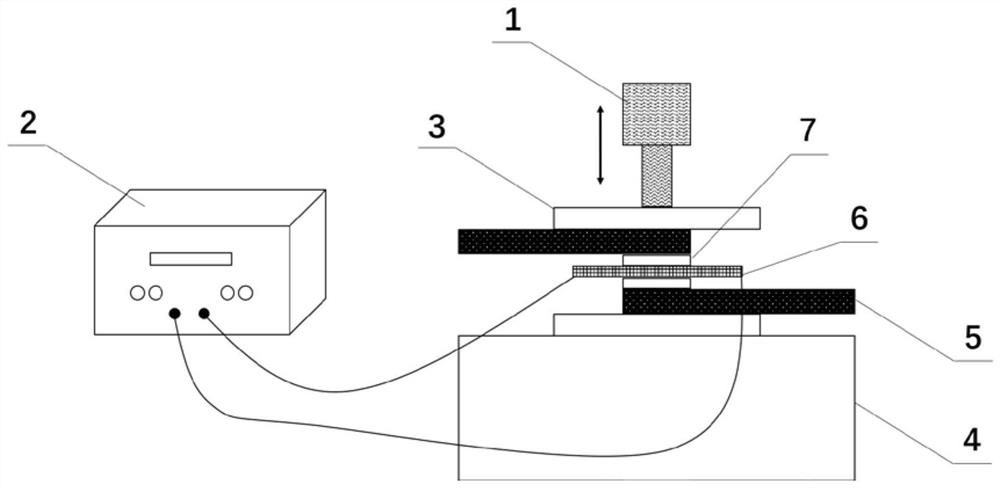

[0028] (1) Build the welding joint according to the internal structure of the welding interface of the resin-based composite material; place the heating element of the PEI film and the stainless steel mesh implant in sequence on the overlapping welding area of the GF-reinforced PEI thermoplastic resin-based (GF / PEI) composite material, See the order of placement figure 1 , to obtain the welded piece to be processed; place the welded piece to be processed in the welding device, the device diagram is shown in figure 2 ;The wire diameter of the selected stainless steel mesh implant heating element is 0.08mm, and the aperture is 0.4mm;

[0029] (2) Turn on the 2-power supply for welding, adjust the current or voltage so that the maximum temperature in the welding area reaches 400°C; the welding time is 90s; at the same time, the vibration fr...

Embodiment 2

[0033]An ultrasonic-resistance hybrid welding method for resin-based composite materials, the specific operation steps are as follows:

[0034] (1) Build the welding joint according to the internal structure of the welding interface of the resin-based composite material; place the heating element of the PEK film and the nickel-chromium alloy wire mesh implant in sequence on the lapping side of the CF-reinforced PEK thermoplastic resin-based (CF / PEK) composite material The welding area is obtained to obtain the welded piece to be processed; the welded piece to be processed is placed in the welding device; the selected nickel-chromium alloy wire mesh implant heating element has a wire diameter of 0.09mm and an aperture of 0.5mm;

[0035] (2) Turn on the power supply for welding, adjust the current or voltage so that the maximum temperature of the welding area reaches 420°C; the welding time is 90s; at the same time, ultrasonic energy with a vibration frequency of 20KHz and an amp...

Embodiment 3

[0039] An ultrasonic-resistance hybrid welding method for resin-based composite materials, the specific operation steps are as follows:

[0040] (1) Build the welding joint according to the internal structure of the welding interface of the resin-based composite material; place the heating element of the PPS film and the iron-chromium-aluminum alloy wire mesh implant in sequence on the joint of the CF-reinforced PPS thermoplastic resin-based (CF / PPS) composite material In the reception welding area, the welded parts to be processed are obtained; the welded parts to be processed are placed in the welding device; the selected iron-chromium-aluminum alloy wire mesh implant heating element has a wire diameter of 0.15mm and an aperture of 0.1mm;

[0041] (2) Turn on the power supply for welding, adjust the current or voltage to make the maximum temperature of the welding area reach 300°C; the welding time is 100s; at the same time, apply ultrasonic energy with a vibration frequency ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com