Electric variable-pitch turboprop engine

A turboprop and engine technology, applied in the direction of motor-driven engines, propellers, machines/engines, etc., can solve the problems that affect the acceleration and deceleration performance of propeller aircraft, the load inertia cannot be changed quickly, and the hydraulic pitch variable mechanism is bulky, etc., to achieve Quickly adjust the blade angle, simple structure, and less system parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

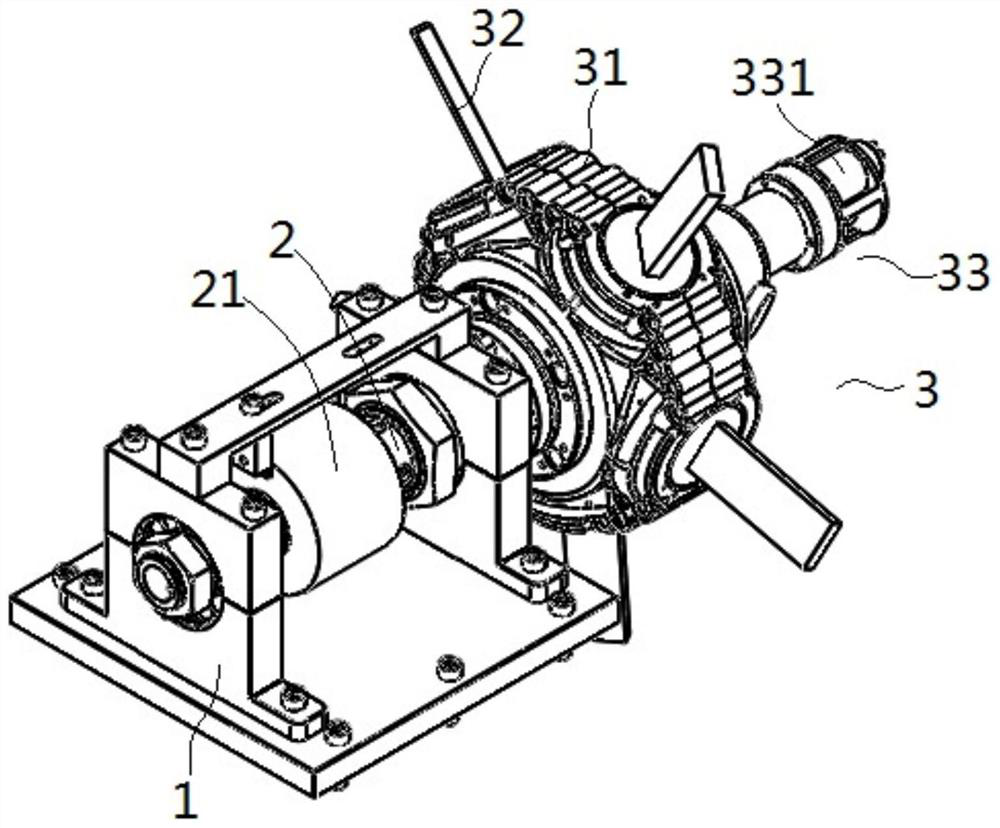

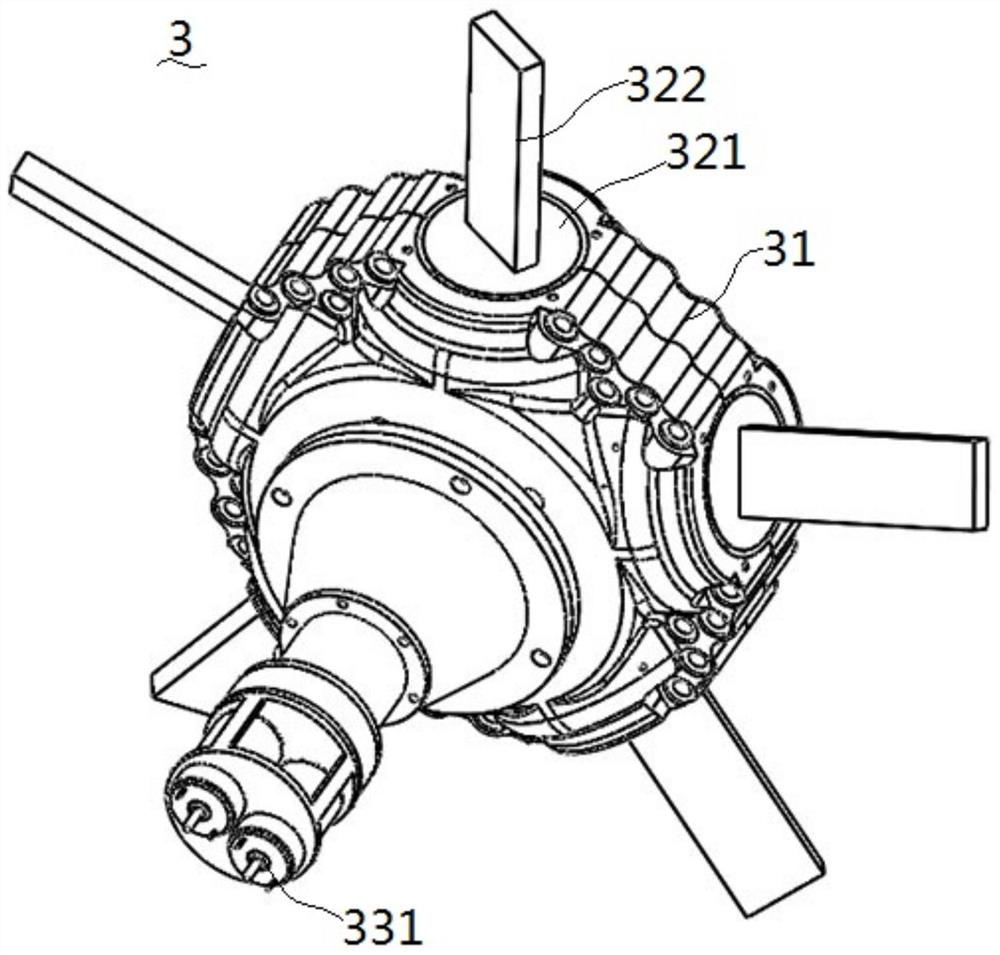

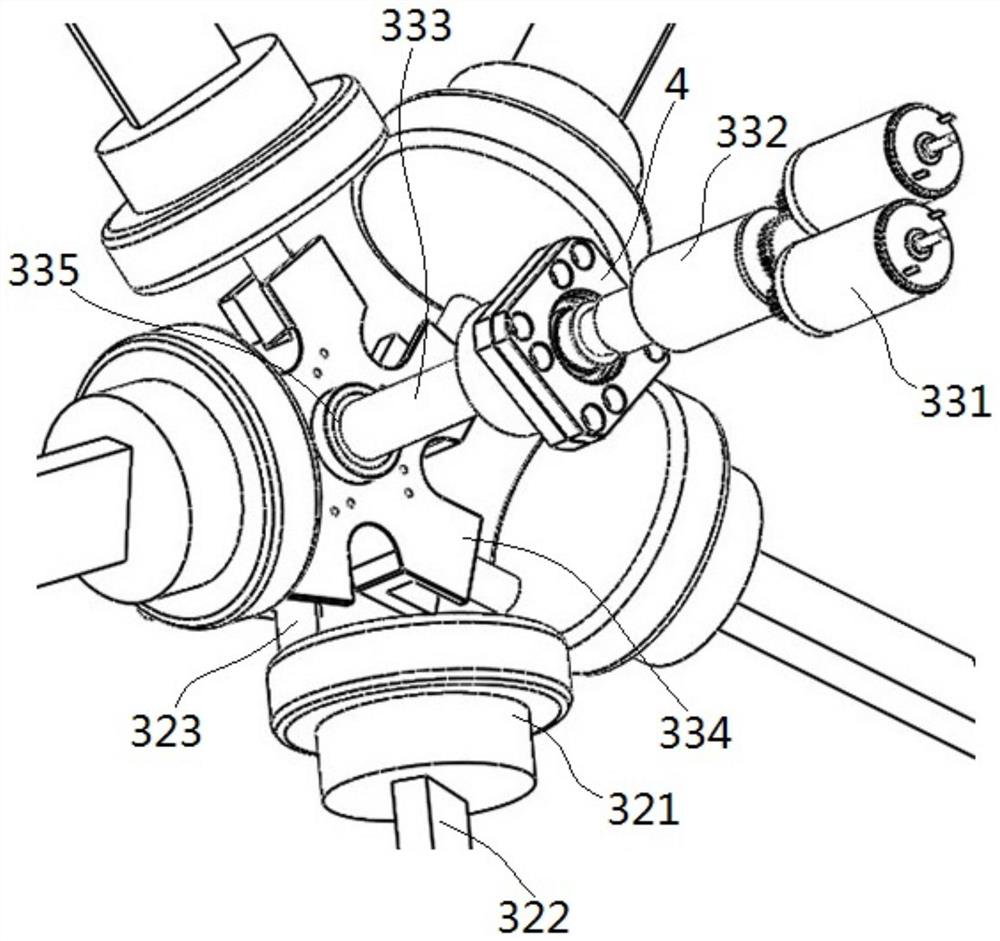

[0048] Specific embodiments of the electric pitch variable turboprop engine of the present invention: the electric pitch variable turboprop engine comprises a gas turbine engine, a speed reduction device and a propeller, and the basic principle of the turboprop engine is an existing mature technology, its working principle, structure, etc. It is easy to find on the browser, and this part of the structure has nothing to do with the improvement of the present invention. It is only necessary to know that the gas turbine engine can drive the propeller to rotate through the deceleration device, so that a pulling force is generated at the propeller to drive the body to move. Here is to save space , no more details. figure 1 Shown is the connection state diagram of the propeller 3 and the main shaft 2 in the prior art, as can be seen from the figure, one end of the propeller 3 is connected with the main shaft 2, and the other end is connected with the pitch-changing mechanism 33, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com