Preparation method of novel polymerized triazine derivative desulfurizing agent

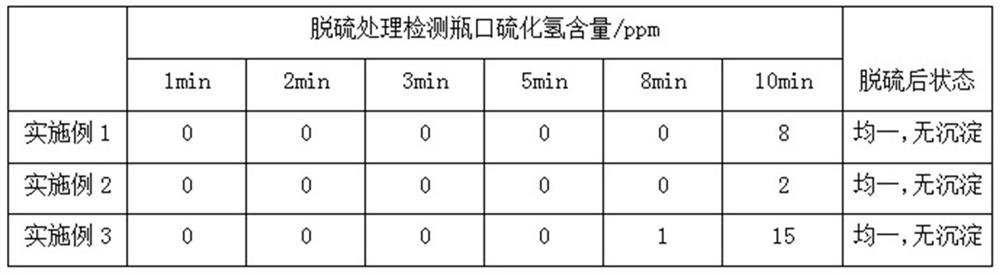

A technology of triazine derivatives and desulfurizers, which is applied in the chemical industry, can solve problems such as scaling, sedimentation and pipe plugging, and achieve the effects of increasing desulfurization rate, increasing desulfurization efficiency, and enhancing desulfurization temperature adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

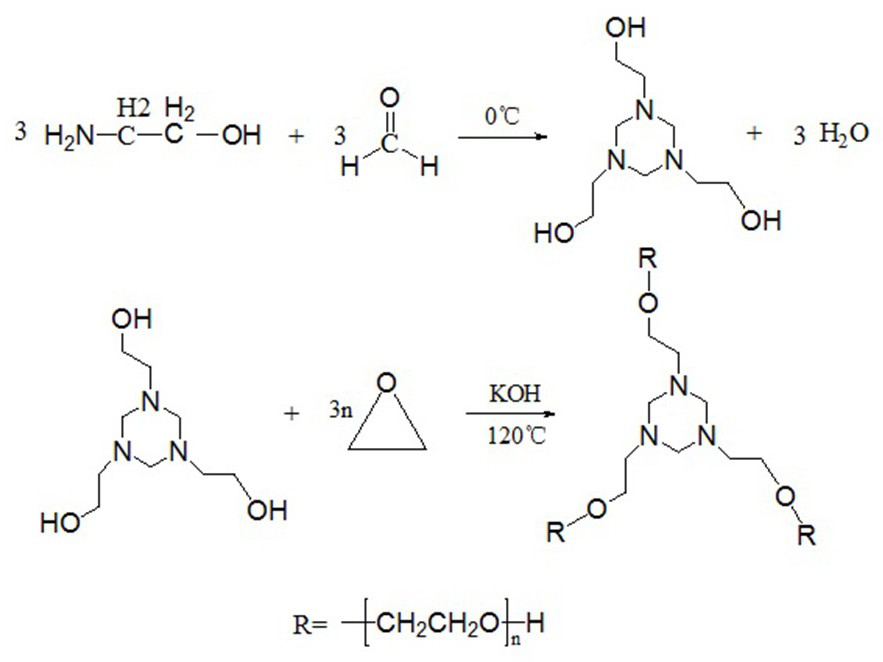

[0018] Such as figure 1 Shown, a kind of preparation method of new polymerization triazine derivative desulfurizer comprises the following steps:

[0019] S1: Add a certain amount of ethanol, formaldehyde and 2-aminoethanol to the reaction kettle, and react at 0°C for a period of time to synthesize hydroxyethylhexahydro-s-triazine;

[0020] S2: Add a certain amount of ethanol, ethylene oxide, hydroxyethylhexahydro-s-triazine and potassium hydroxide prepared in step S1 to another reaction kettle, raise the temperature to 120°C, and continue under the catalytic action of potassium hydroxide After reacting for a period of time, the target desulfurizer can be obtained.

[0021] Preparation of hydroxyethylhexahydro-s-triazine:

[0022] Add 5mol of formaldehyde, 5mol of 2-aminoethanol and 200ml of ethanol into the reaction kettle, stir, react at 0°C for 2h, keep warm for 1h, separate and purify to obtain hydroxyethylhexahydro-s-triazine.

Embodiment 1

[0024] Add 100ml of ethanol to the reaction kettle as a solvent, add 1mol of prepared hydroxyethylhexahydro-s-triazine, 0.1mol of ethylene oxide and 0.5mol of potassium hydroxide, stir, raise the temperature to 120°C, and react for 3 hours to obtain the target desulfurizer .

Embodiment 2

[0026] Add 100ml of ethanol into the reaction kettle as a solvent, add 1mol of prepared hydroxyethylhexahydro-s-triazine, 0.3mol of ethylene oxide and 1mol of potassium hydroxide, stir, raise the temperature to 120°C, and react for 3 hours to obtain the target desulfurizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com