Freeze-drying device for aminated graphene production

A technique of aminated graphene and freeze-drying, which is applied in drying, drying machines, and drying solid materials, etc., can solve the problem that aminated graphene cannot be uniformly freeze-dried, takes a long time to completely freeze-dry, and cannot condense water Dealing with other problems, to achieve the effect of shortening the required time, improving the cooling effect and improving the practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

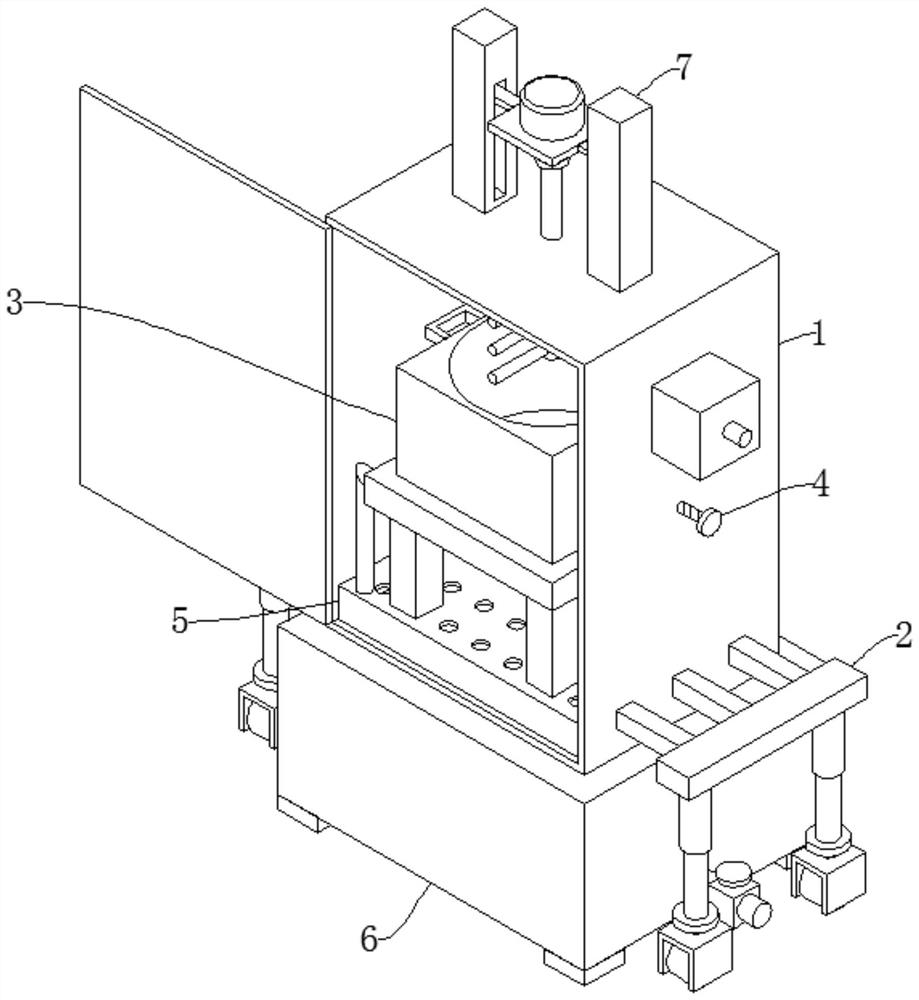

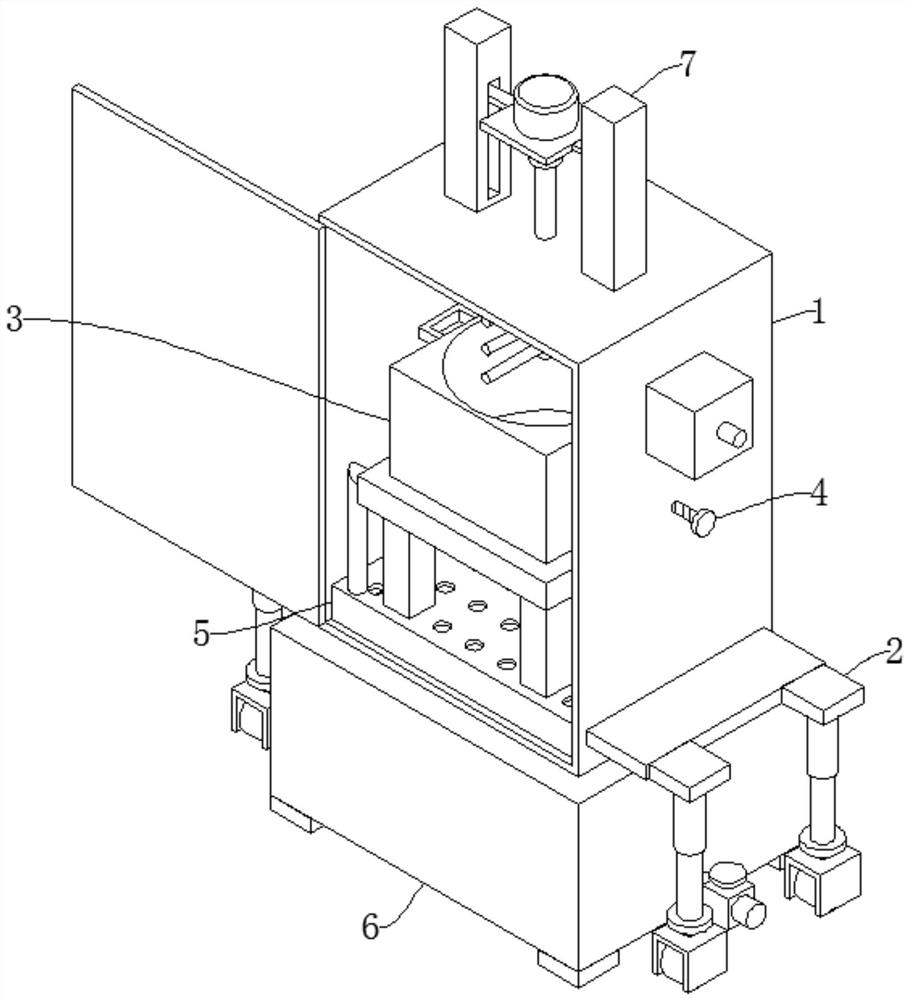

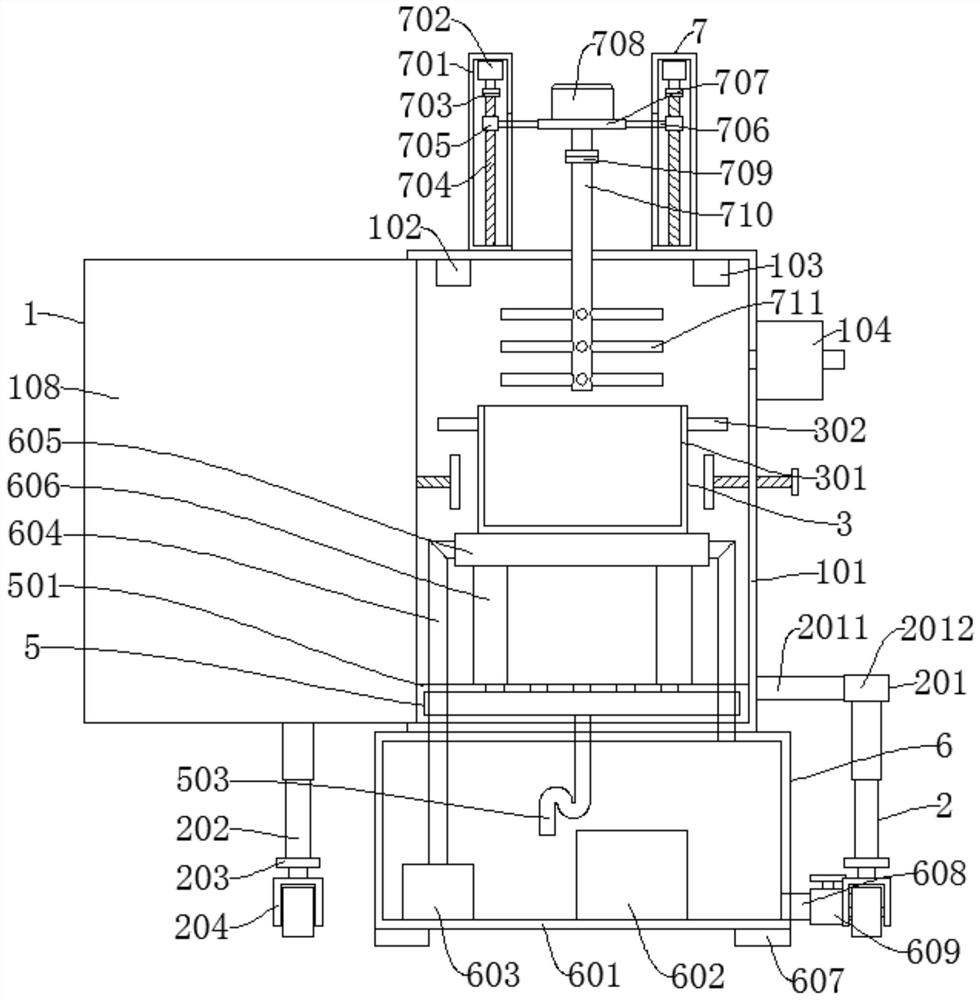

[0045] Such as figure 1 , image 3 , Figure 5 , Figure 7 , Figure 8 As shown, a freeze-drying device for the production of aminated graphene includes a closing mechanism 1, a moving mechanism 2 for driving the device to move, a storage mechanism 3, and a fixing mechanism 4, and a moving mechanism 2 is installed on both sides of the closing mechanism 1 , the inside of the closing mechanism 1 is provided with a storage mechanism 3, and both sides of the storage mechanism 3 are provided with a fixing mechanism 4, which also includes a recovery mechanism 5, a cooling mechanism 6, and a stirring mechanism 7. The recovery mechanism 5 is fixed on the closure mechanism 1, and the cooling mechanism 6 is installed Below the closing mechanism 1, the stirring mechanism 7 is fixed above the closing mechanism 1;

[0046] Closing mechanism 1 comprises closed case 101, temperature and humidity sensor 102, air pressure sensor 103, vacuum pump 104, curved rod 105, mounting plate 106, ads...

Embodiment 2

[0056] Such as figure 2 , Figure 4 , Figure 6 , Figure 7 , Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that the fixed rod 2011 and the fixed bar 2012 are replaced by the fixed plate 2013 and the fixed block 2014. The moving wheel 204 is lowered to touch the ground to push the device to move, and the fixed plate 2013 and the fixed block 2014 work together to support and fix the electric push rod 202 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com