Probe for measuring thermal conductivity and preparation method thereof

A technology of thermal conductivity and nickel strip, which is applied in the field of thermal conductivity test probes, can solve problems such as poor repeatability of measurement results, influence on experimental progress, shorten service life, etc., and achieve the effect of avoiding line sequence errors, firm service life and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

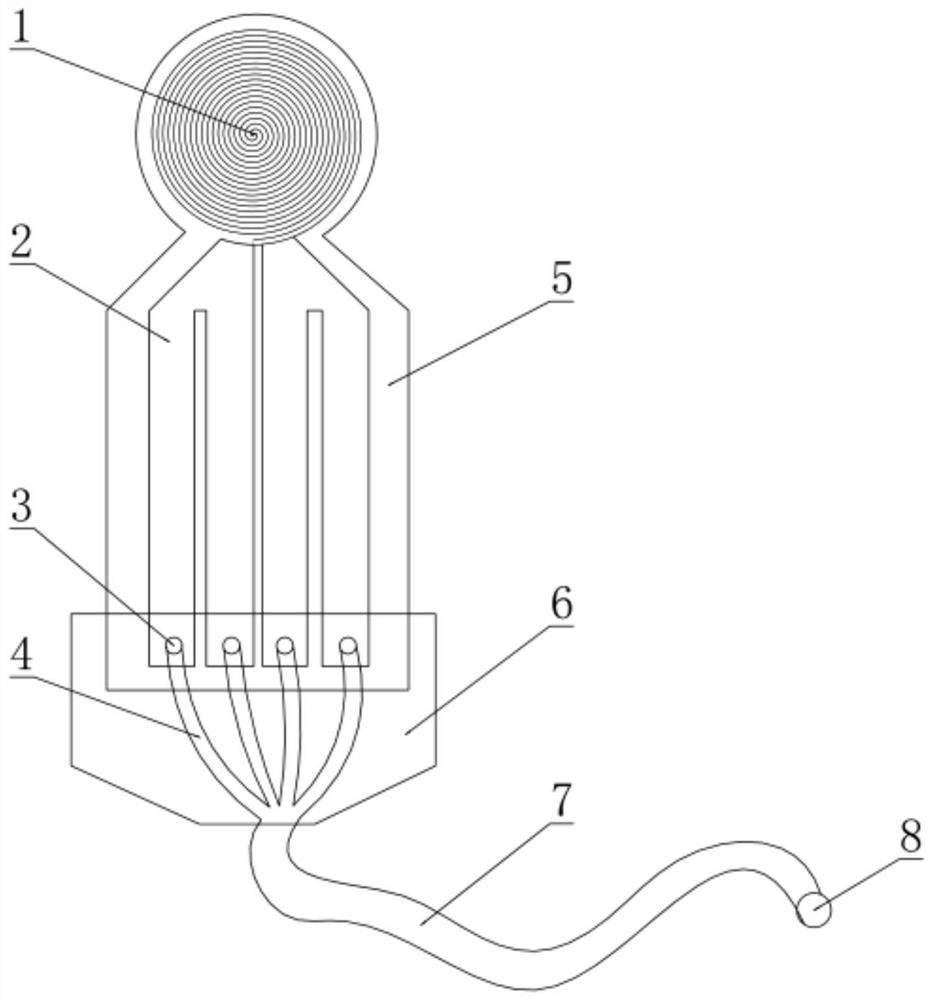

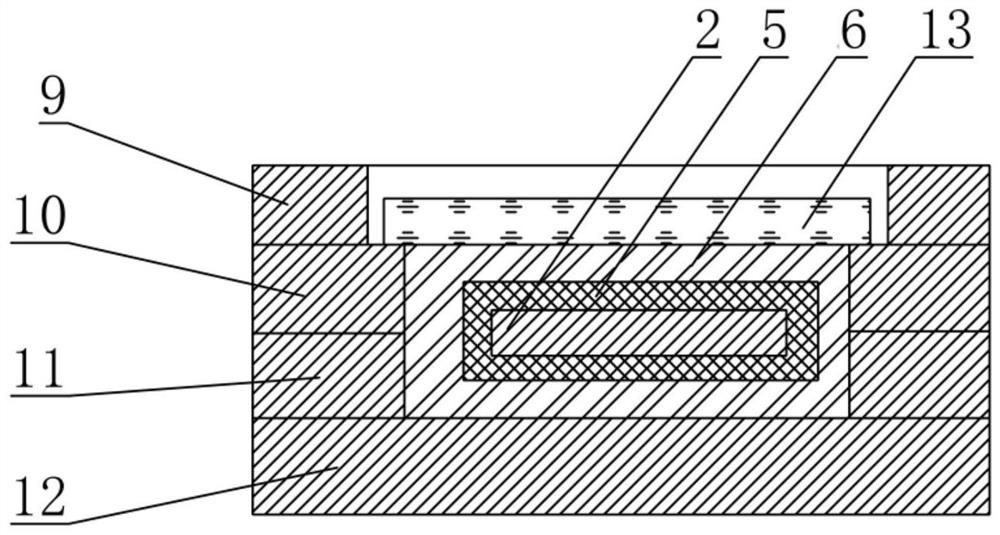

[0046] Such as figure 1As shown, a probe for measuring thermal conductivity includes: a probe body, a cable 7, an insulating layer 6 and a plug 8, the probe body is a sandwich structure, and the sandwich structure is composed of a metal layer and 2 insulating layers 5, 2 pieces A metal layer is sandwiched between the insulating layers 5, and the insulating layer 5 plays the role of insulation and increasing mechanical strength. The head of the metal layer is a planar double helix structure 1, and a metal nickel strip forms a planar double helix structure 1 from the inside to the periphery, and the two ends of the metal nickel strip extend from the tail of the plane double helix structure 1 towards the tail of the metal layer and Each end of the metal nickel strip forms 2 nickel strips 2, and 4 nickel strips 2 form the tail of the metal layer. A lead wire 4 is welded on each nickel strip 2, and a welding point 3 is formed at the welding place. One end of the cable 7 is connecte...

Embodiment 2

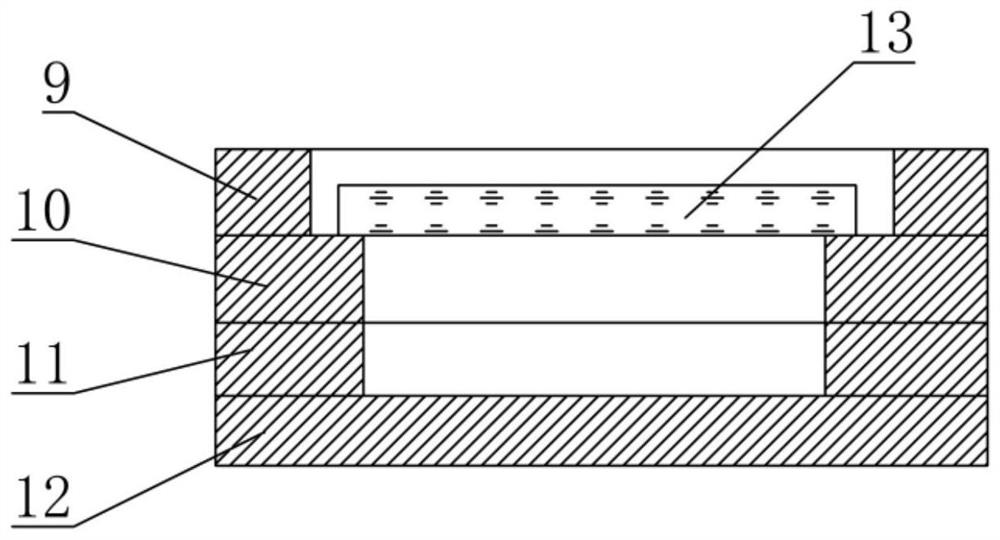

[0048] On the basis of Embodiment 1, the edge of the insulating layer 5 protrudes from the side edge of the metal layer by a distance of 1-5 mm, for example, 2 mm. The material of the insulating layer 5 can be polyimide. When the material of the insulating layer 5 is polyimide, according to the heat resistance of the material selected for the insulating layer 5 , the normal working temperature range of the probe is -50-230°C. When the material of the insulating layer 5 is mica, the normal working temperature range of the probe is -50~1000℃

[0049] The thickness of the insulating layer 5 is 7-100 μm, for example, 50 μm.

[0050] The outer diameter of the double helix structure is related to the width of the metal nickel ribbon and the number of double helix turns, specifically, the outer diameter of the double helix structure=the width of the metal nickel ribbon*the number of turns*4. The outer diameter of the double helix structure is 4-100 mm, for example, 4.8 mm.

[0051...

Embodiment 3

[0059] On the basis of Embodiment 2, the connection method between the lead wire 4 and the nickel strip 2 is: one end of the lead wire 4 penetrates through the insulating layer 5 and is welded to the nickel strip 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com