C/TiN coated lithium tritium orthosilicate breeding agent and preparation method and preparation device system thereof

A technology of a tritium multiplication agent and a coating device, which is applied in the field of nuclear fusion and can solve the problems of difficult mass production, direct contact, low heat transfer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

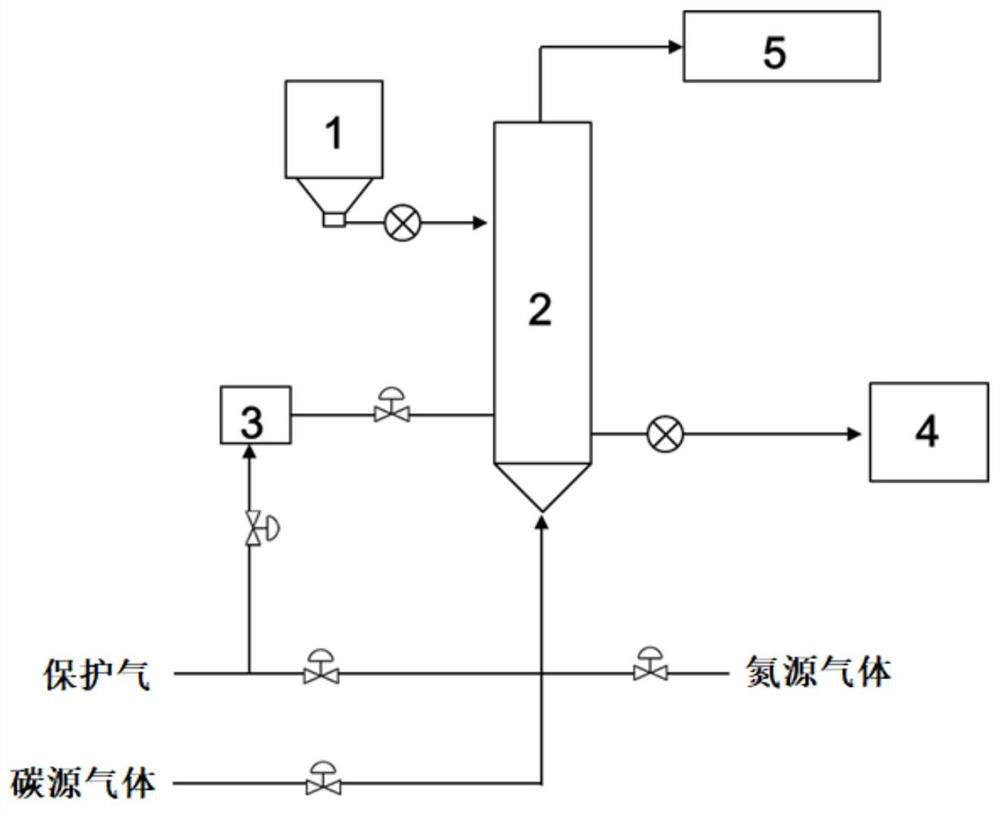

[0064] This embodiment provides a C / TiN coated Li 4 SiO 4 The preparation method of tritium multiplying agent, described preparation method provided in the present invention such as figure 1 Carry out in the shown device system, described preparation method comprises the following steps:

[0065] (1) Spherical Li with a particle size of 0.6mm 4 SiO 4 The particles are in a fluidized state in the protective atmosphere of argon;

[0066] (2) On the basis of continuing the step (1), the titanium source gas and the nitrogen source gas are independently fed into the Li 4 SiO 4 In the protective atmosphere where the particles are located, TiN-coated Li 4 SiO 4 Particles; the mixing temperature is 700°C, and the mixing time is 30 minutes; the titanium source gas is a gas formed after titanium dichloride is vaporized at a high temperature of 600°C, the carrier gas is argon, and the gas velocity is 125mL / min; Described nitrogen source gas is nitrogen, and gas velocity is 125mL / ...

Embodiment 2

[0072] This embodiment provides a C / TiN coated Li 4 SiO 4 The preparation method of tritium multiplying agent, described preparation method provided in the present invention such as figure 1 Carry out in the shown device system, described preparation method comprises the following steps:

[0073] (1) Make spherical Li with an average particle size of 0.9mm 4 SiO 4 Particles are in a fluidized state in a protective atmosphere of helium;

[0074] (2) On the basis of continuing the step (1), the titanium source gas and the nitrogen source gas are independently fed into the Li 4 SiO 4 In the protective atmosphere where the particles are located, TiN-coated Li 4 SiO 4 Particles; the mixing temperature is 800°C, and the mixing time is 45min; the titanium source gas is a gas formed after titanium dichloride is vaporized at a high temperature of 700°C, the carrier gas is helium, and the gas velocity is 160mL / min; Described nitrogen source gas is nitrogen, and gas velocity is 1...

Embodiment 3

[0079] This embodiment provides a C / TiN coated Li 4 SiO 4 The preparation method of tritium multiplying agent, described preparation method provided in the present invention such as figure 1 Carry out in the shown device system, described preparation method comprises the following steps:

[0080] (1) Spherical Li with a particle size of 0.3mm 4 SiO 4 The particles are in a fluidized state in a protective atmosphere of neon;

[0081] (2) On the basis of continuing the step (1), the titanium source gas and the nitrogen source gas are independently fed into the Li 4 SiO 4 In the protective atmosphere where the particles are located, TiN-coated Li 4 SiO 4 Particles; the mixing temperature is 600°C, and the mixing time is 15 minutes; the titanium source gas is the gas formed after titanium dichloride is vaporized at a high temperature of 500°C, the carrier gas is neon gas, and the gas velocity is 85mL / min; The nitrogen source gas is nitrogen, and the gas velocity is 85mL / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Equivalent diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com