A kind of catalyst preparation method

A catalyst and catalyst carrier technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of competitive adsorption of catalytic liquid, waste of catalytic liquid, and inability to spray uniformly of catalytic liquid, etc. To achieve the effect of improving the catalytic effect, increasing the contact time and increasing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

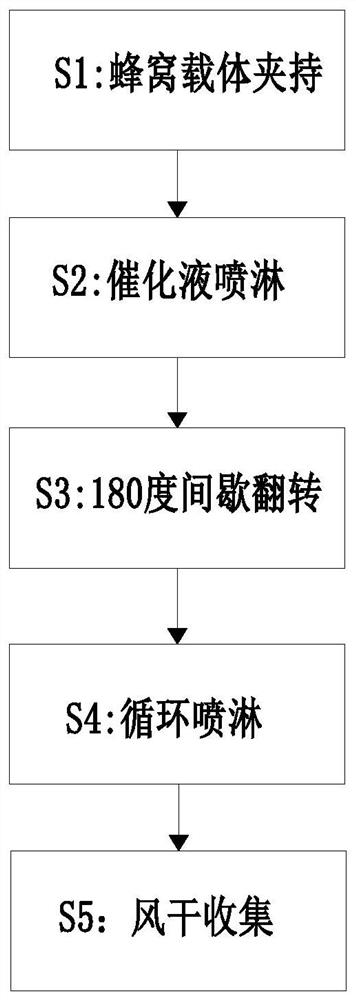

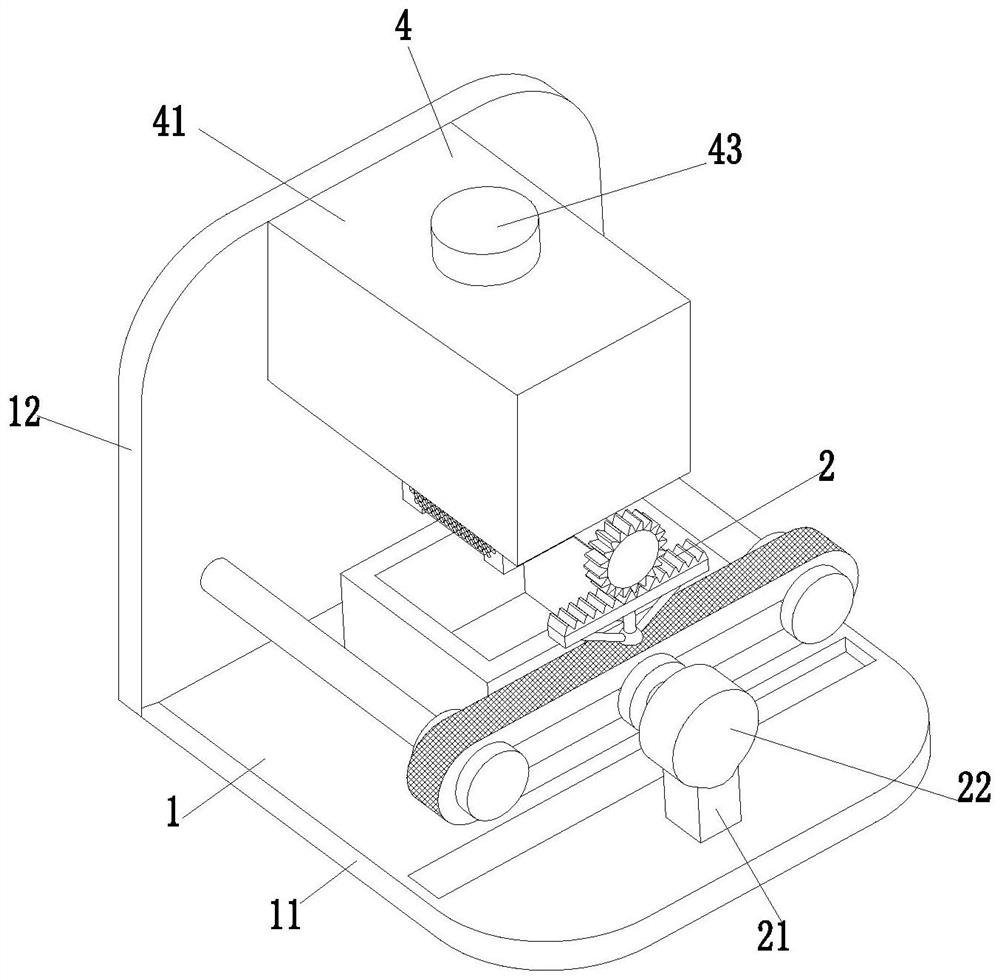

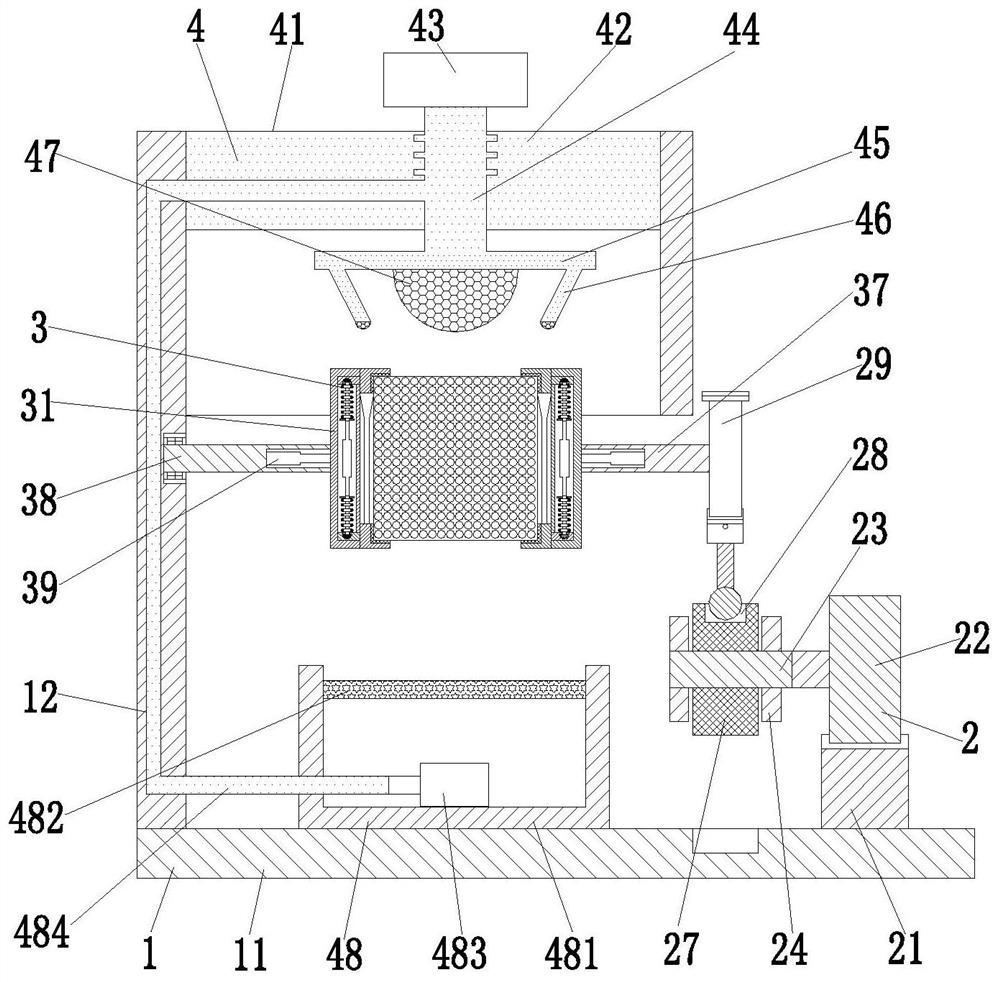

[0034] Such as Figure 1 to Figure 6As shown, a catalyst preparation method, which uses a catalyst preparation device, the catalyst preparation device includes a support plate 1, a turning mechanism 2, a clamping mechanism 3 and a spray mechanism 4, and the support plate 1 includes a support horizontal Plate 11 and supporting vertical plate 12, the middle part of the upper end surface of supporting horizontal plate 11 is equipped with an overturning mechanism 2, the clamping mechanism 3 is installed on the overturning mechanism 2, and the spraying mechanism 4 is installed on the supporting vertical plate 12, and the spraying mechanism 4 is located in the clip above the holding mechanism 3.

[0035] The clamping mechanism 3 includes a clamping plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com