Cabinet door plate machining system and material distributing and drilling line arrangement method thereof

A technology of processing system and layout method, which is applied in the direction of wood processing equipment, manufacturing tools, fixed drilling machines, etc., can solve the problems of not being able to supply cabinet door panels well, affecting the processing efficiency of cabinet door panels, and low processing and production efficiency. Improve drilling efficiency, ensure drilling quality, and ensure the effect of drilling operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

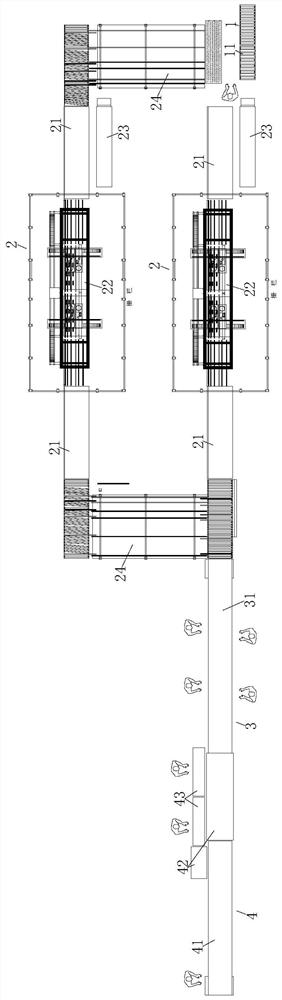

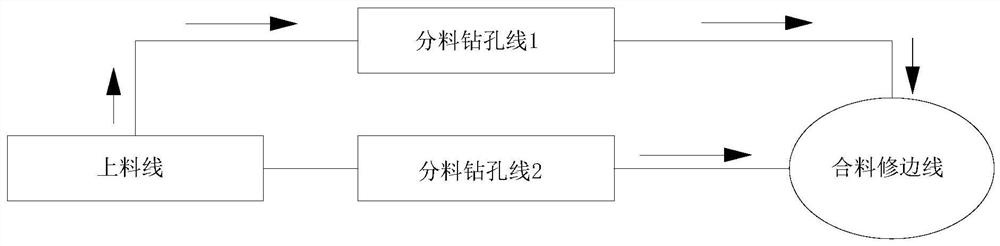

[0065] see figure 2 , when there are two even-numbered material-distributing drilling lines, the two material-distributing drilling lines are arranged semi-symmetrically.

[0066] In the specific layout, the length of the assembly line of one of the sub-drilling lines is lengthened by adding a roller transfer table, etc., and the output distance between the two adjacent plates to be processed on the two sub-drilling lines is staggered to ensure that the two The plate to be processed on the strip material drilling line can be smoothly transported to the next process.

[0067] For example, when two material-distributing drilling lines are arranged parallel to each other, a roller transfer platform can be set at both the feeding end and the discharging end of one of the material-distributing drilling lines. The roller transmission table set at the material end can change the conveying direction of the plate to be processed, so that the plate to be processed on each material dis...

specific Embodiment 2

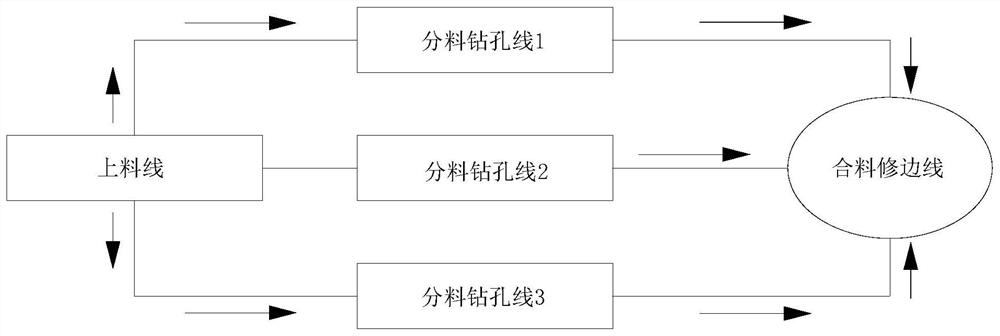

[0069] see image 3 , when the distribution drilling lines are an odd number of three, the three distribution drilling lines are symmetrically arranged.

[0070] In the specific layout, the three material distribution drilling lines are arranged parallel to each other and at equal intervals. The output spacing between two adjacent plates to be processed is staggered to ensure that the plates to be processed on the three distribution drilling lines can be smoothly conveyed to the next process.

[0071] For example, when three sub-material drilling lines are arranged parallel to each other, the middle sub-material drilling line is on the same line as the feeding line, and the other two sub-material drilling lines are symmetrical about the middle sub-material drilling line Arrangement, the roller transmission table is set at the feed end and the discharge end of the two-part material drilling line located on both sides of the middle material distribution drilling line, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com