Radial extruder gas supply device, gas source adapter, radial extruder and machining method

A technology of air supply device and adapter, which is applied in the field of concrete pipeline processing equipment, can solve the problems of high energy consumption, excessive dust, and inaccurate docking of cylinders, so as to improve the accuracy of air supply, ensure work efficiency, and prevent deviation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] Explanation of some terms in the present invention:

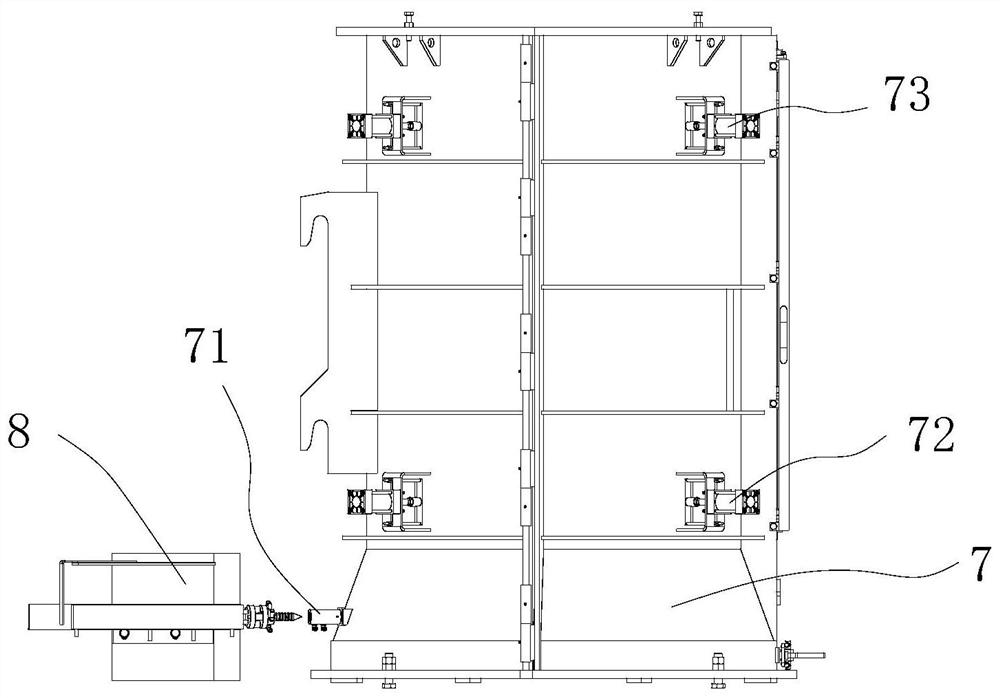

[0077] Work into: drive the upper / lower fixed cage plate (731, 721) of the mold to do the insertion action;

[0078] Retirement from work: drive the upper / lower fixed cage inserts (731, 721) of the mold to perform the withdrawal action.

[0079] Among all the technical features of the present invention, the "A hole" and "B hole" are respectively an airway in the same direction;

[0080] Further describe the present invention below in conjunction with accompanying drawing,

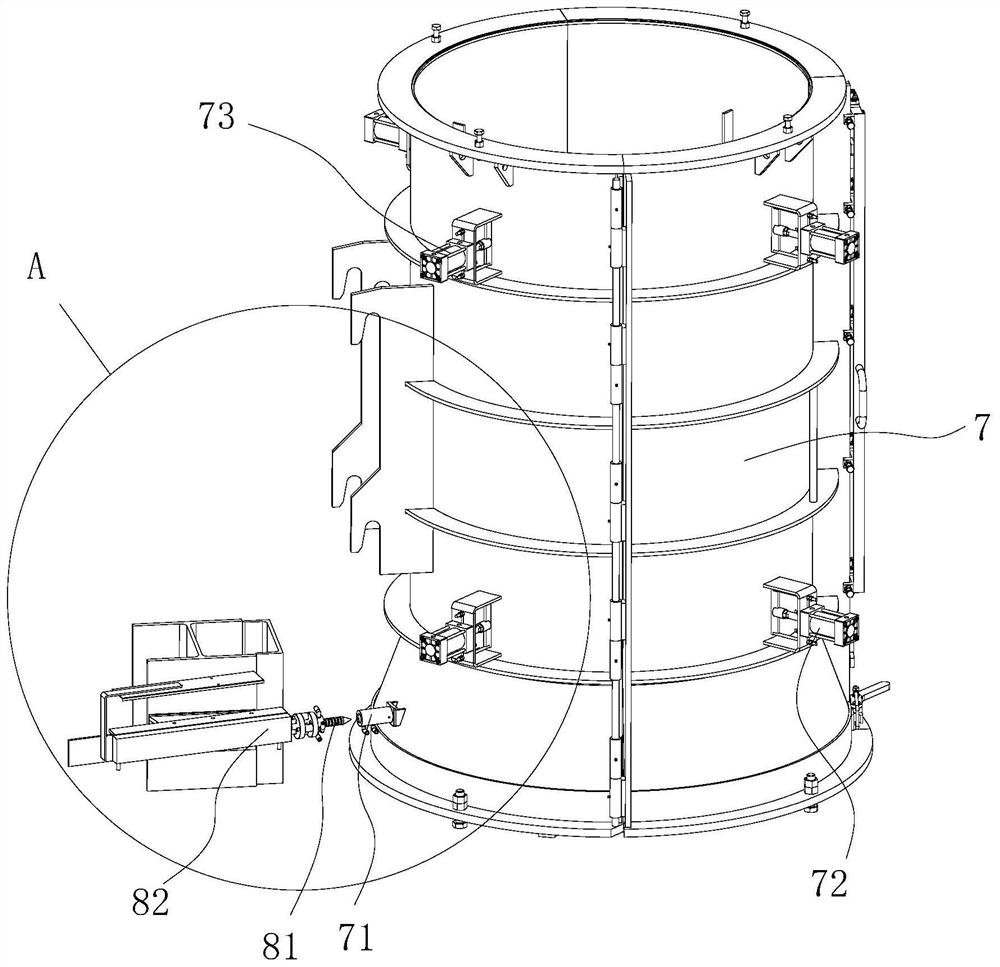

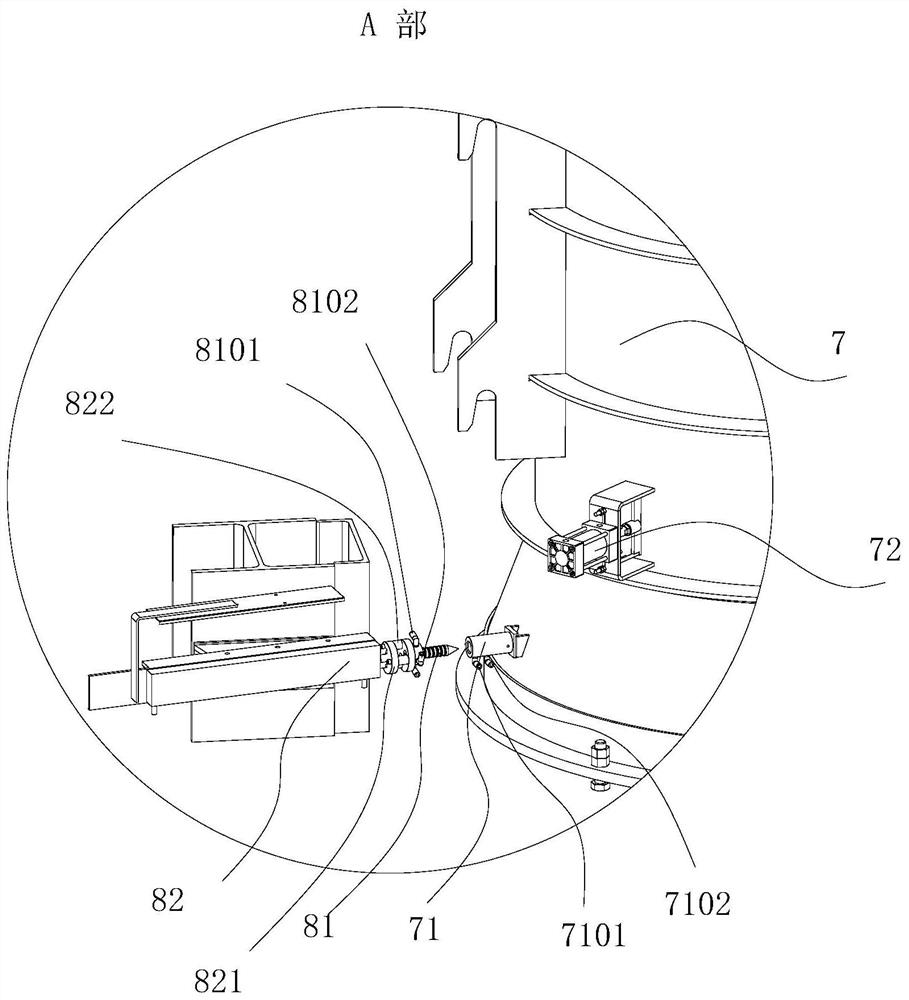

[0081] Such as Figure 1-8 As shown, the air supply device 8 includes an air source, a base, an air supply head driving cylinder 82 and an air supply head 81, the air supply head 81 is connected to the piston rod end of the air supply head driving cylinder 82, and the air supply head 81 includes a supply Air head base 811, air supply head working section 812 and conical head end 813; The connection hole 8113 of the base realizes the connection...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap