Preparation method of cerium oxide with specific mixed valence state

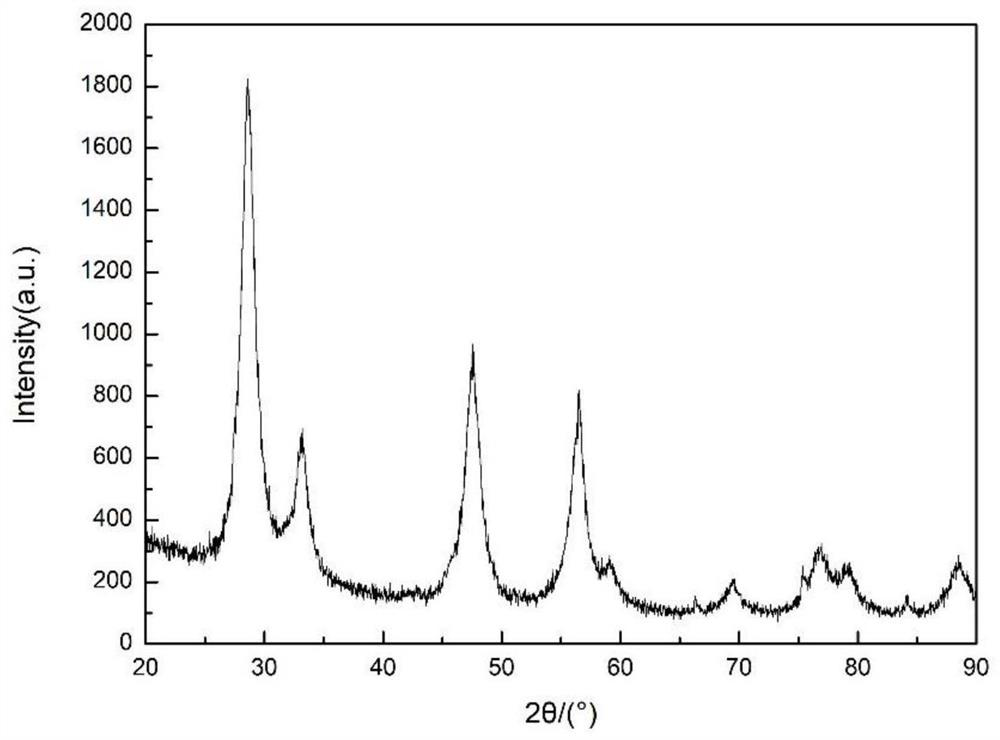

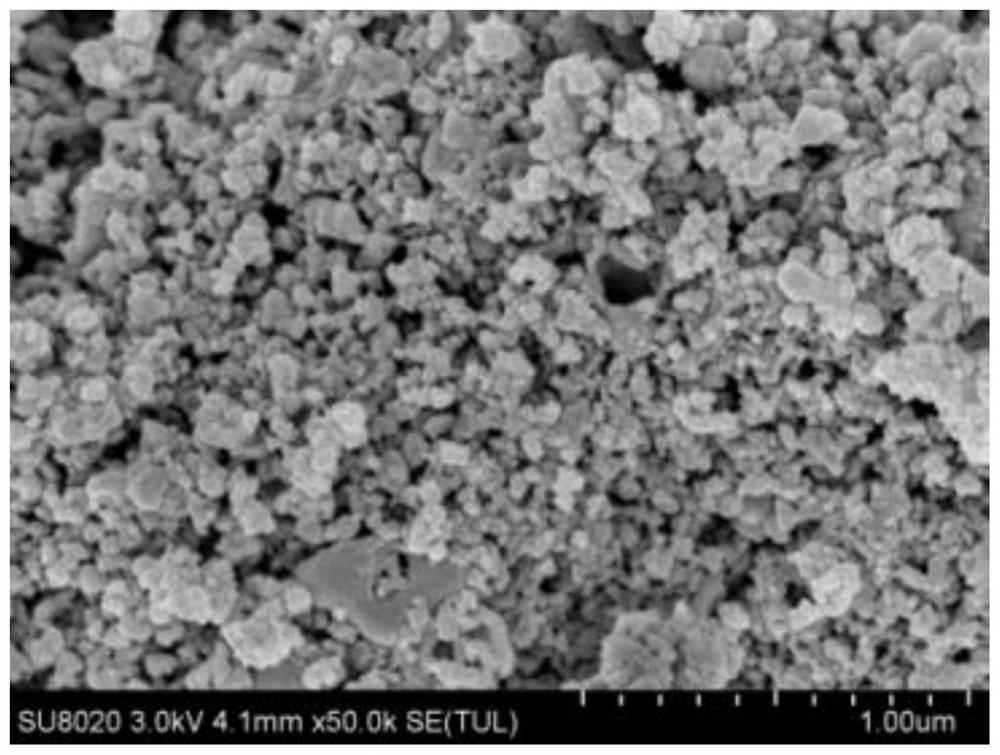

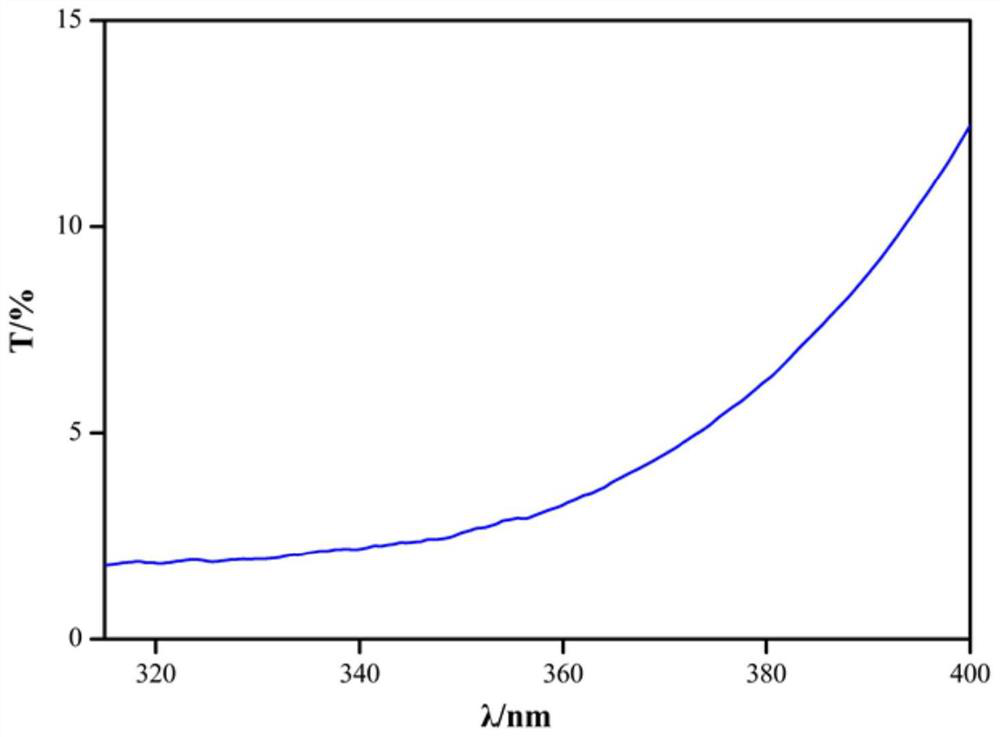

A mixed valence state, cerium oxide technology, applied in the preparation/treatment of rare earth metal compounds, cerium oxide/cerium hydroxide, rare earth metal oxide/hydroxide, etc., can solve the problem of narrow width and achieve grain size Small, good UV shielding effect, wide wavelength UV shielding effect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a method for preparing cerium oxide in a specific mixed valence state, comprising the following steps:

[0034] (1) Under the condition that the temperature of the aqueous solution of trivalent cerium salt is 20-50°C and stirring continuously, the complexing agent and the templating agent are successively added into the aqueous solution of trivalent cerium salt with a peristaltic pump to obtain a mixed solution; The pump adds a pH regulator to the mixed solution until the pH of the mixed solution is 2 to 6; among them, the complexing agent and Ce 3+ The molar ratio of the template agent to Ce is 0.3 to 3:1. 3+ The molar ratio is 0.01~1:1;

[0035] (2) After the mixed solution is adjusted to the specified pH, continue stirring for 10-60 minutes, filter and dry to obtain the precursor of cerium oxide powder;

[0036] (3) Roast the precursor of cerium oxide powder in a spray roaster at 200-500° C. in a spray roaster, and cool the roasted product to...

Embodiment 1

[0043] Under the condition that the temperature of cerium chloride aqueous solution is 20°C and stirring continuously, the citric acid solution with a concentration of 3 mol / L and the glucose solution with a concentration of 3 mol / L are successively added chlorine with a concentration of 0.5 mol / L cerium ion by a peristaltic pump. cerium oxide aqueous solution to obtain a mixed solution; then, a peristaltic pump was used to add a sodium hydroxide solution with a concentration of 10 mol / L to the above mixed solution until the pH value of the mixed solution was 6. Among them, citric acid and Ce 3+ The molar ratio of glucose to Ce is 0.3:1 3+ The molar ratio is 0.01:1.

[0044] After the mixed solution was adjusted to a pH of 6, the stirring was continued for 10 minutes, filtered and then dried to obtain a precursor of cerium oxide powder.

[0045] The precursor of cerium oxide powder is roasted at 500°C by spray roasting in a spray roaster, and the roasted product is cooled to...

Embodiment 2

[0048] Under the condition that the temperature of cerium nitrate aqueous solution is 50°C and it is constantly stirred, EDTA solution with a concentration of 0.05 mol / L and a solution of polyethylene glycol with a concentration of 0.05 mol / L are successively added to the cerium ion concentration of 0.5 mol with a peristaltic pump. / L of cerium nitrate aqueous solution to obtain a mixed solution; Among them, EDTA and Ce 3+ The molar ratio of polyethylene glycol to Ce is 3:1. 3+ The molar ratio is 1:1.

[0049] After the mixed solution was adjusted to a pH of 2, the stirring was continued for 60 minutes, filtered and then dried to obtain a precursor of cerium oxide powder.

[0050] The precursor of cerium oxide powder is roasted at 200°C by spray roasting in a spray roaster, and the roasted product is cooled to room temperature with inert gas at the product collection point of the spray roaster to obtain trivalent cerium quality The cerium oxide powder with a content of 60% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com