Method for preparing single crystal NCMA precursor material

A precursor and single crystal technology, which is applied in the field of preparing single crystal NCMA precursor materials, can solve the problems of performance degradation of positive electrode materials, enrichment of aluminum ion content, etc., and achieves improved tap density, improved electrochemical performance, and good market application. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

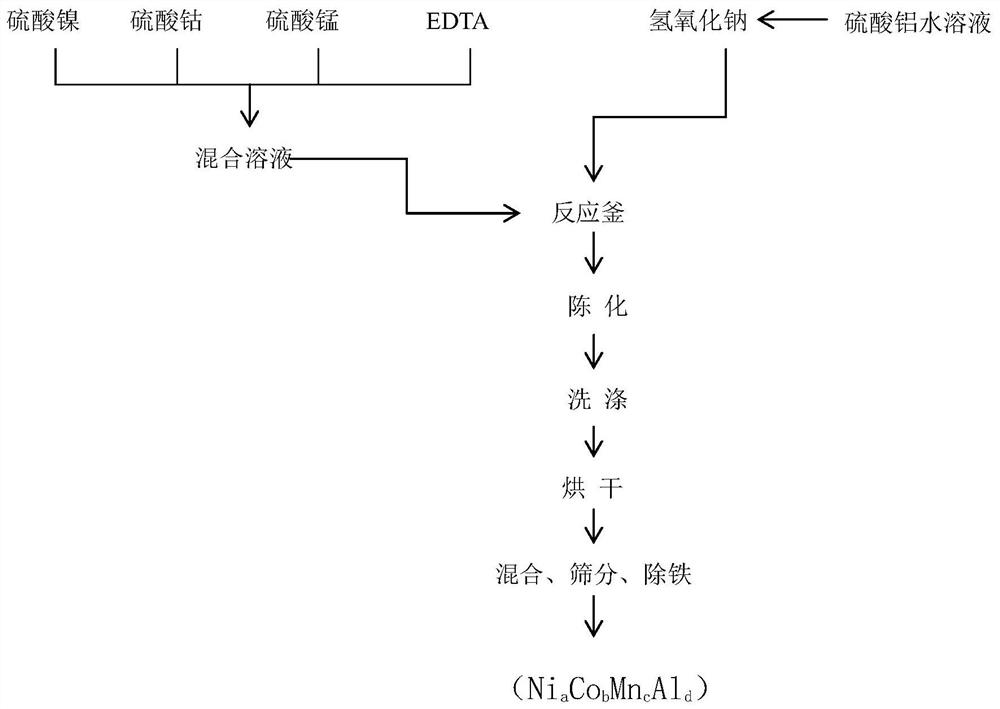

Method used

Image

Examples

Embodiment 1

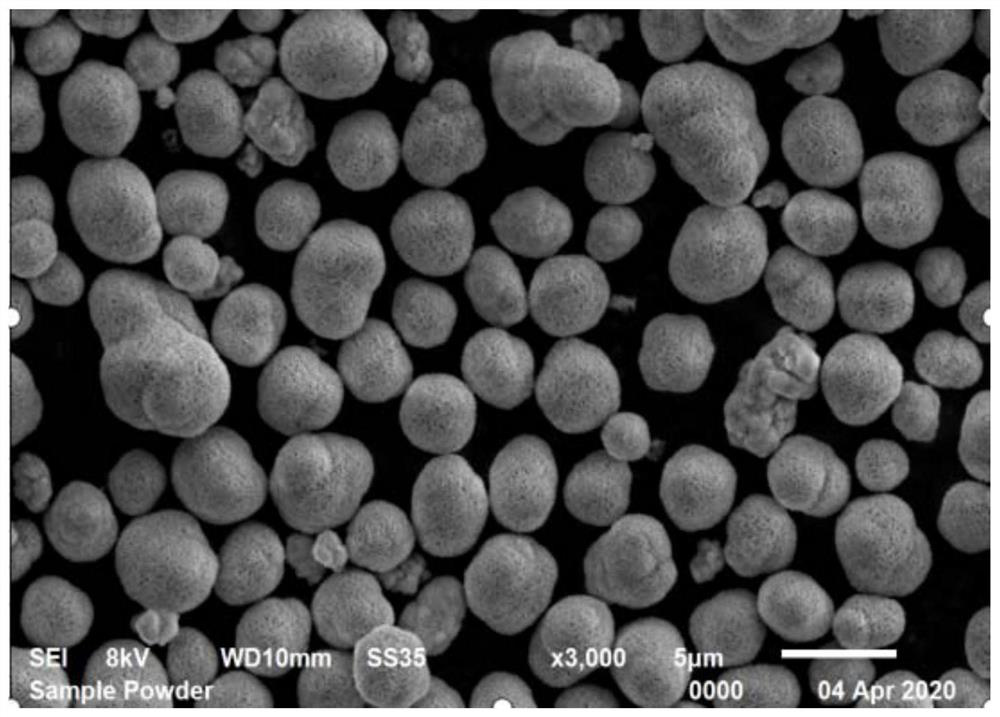

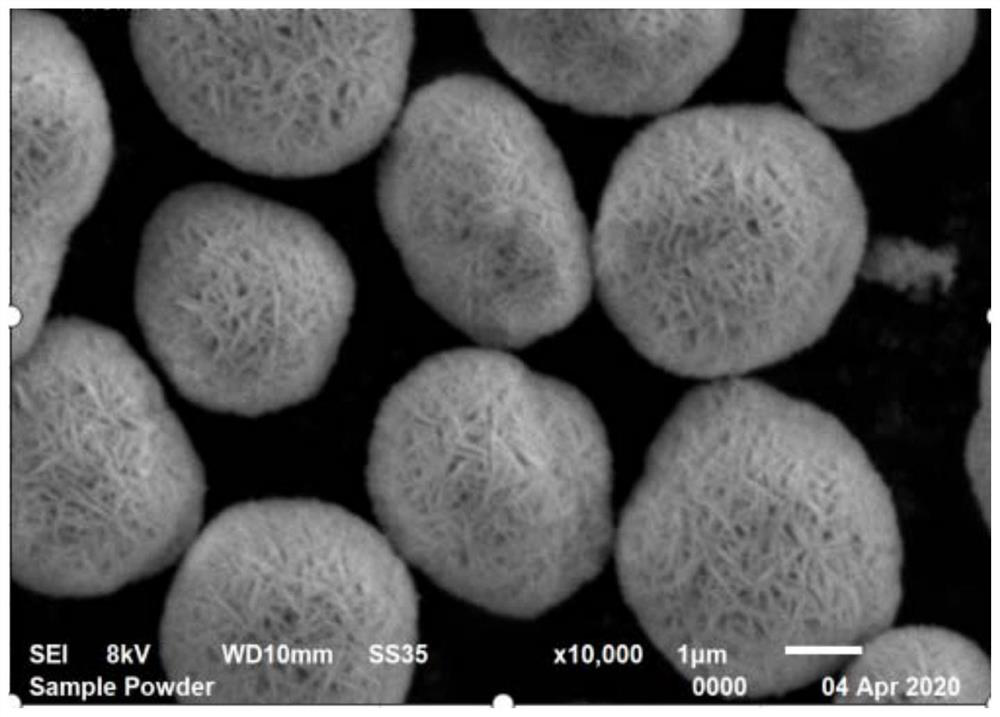

[0033] Step 1, prepare solution B: Weigh 1.5Kg of aluminum sulfate and slowly add it to 5L of pure water; Step 2, prepare solution C: use a peristaltic pump to pump solution B into 45L of 5mol / L hydrogen hydroxide at a rate of 5L / h In the sodium solution, prepare solution C; Step 3, prepare solution A: NiSO with a concentration of 1.5mol / L 4 、CoSO 4 , MnSO 4 The three solutions were prepared according to the volume ratio of 85:5:5, with a concentration of 1.5mol / L NiSO 4 、CoSO 4 , MnSO 4 Mixed solution, and add EDTA to be mixed with the mixed solution A that EDTA molar concentration is 0.1mol / L. Use a peristaltic pump to pump solution C and solution A into a 50L reactor, and use the main and auxiliary bases to control the pH of the reactor; solution C is the main base with a fixed flow rate of 2L / h; the auxiliary base is hydrogen with a concentration of 5mol / L Sodium oxide solution controls the pH of the reactor, and the solution A flow rate is 3L / h. Control the temperat...

Embodiment 2

[0036] Step 1, prepare solution B: Weigh 1.5Kg of aluminum sulfate and slowly add it to 5L of pure water; Step 2, prepare solution C: use a peristaltic pump to pump solution B into 45L of 5mol / L hydrogen hydroxide at a rate of 5L / h In the sodium solution, be prepared into solution C; Step 3, prepare solution A: the NiSO with concentration all 1.8mol / L 4 、CoSO 4 , MnSO 4 The three solutions were prepared according to the volume ratio of 88:6:3, with a concentration of 1.8mol / L NiSO 4 、CoSO 4 , MnSO 4 Mixed solution, and add EDTA to be mixed with the mixed solution A that EDTA molar concentration is 0.1mol / L. Use a peristaltic pump to pump solution C and solution A into a 50L reactor, and use the main and auxiliary bases to control the pH of the reactor; solution C is the main base with a fixed flow rate of 1.5L / h; the auxiliary base is 5mol / L Sodium hydroxide solution controls the pH of the reactor, and the solution A flow rate is 3L / h. Control the temperature of the reac...

Embodiment 3

[0039] Step 1, prepare solution B: Weigh 1.5Kg of aluminum sulfate and slowly add it to 5L of pure water; Step 2, prepare solution C: use a peristaltic pump to pump solution B into 45L of 5mol / L hydrogen hydroxide at a rate of 5L / h In the sodium solution, prepare solution C; Step 3, prepare solution A: the concentration is 2mol / L NiSO 4 、CoSO 4 , MnSO 4 The three solutions were prepared according to the ratio of 90:8:1, with a concentration of 2.0mol / L NiSO 4 、CoSO 4 , MnSO 4 Mixed solution, and add EDTA to be mixed with the mixed solution A that EDTA molar concentration is 0.1mol / L. Use a peristaltic pump to pump solution C and solution A into a 50L reactor, and use the main and auxiliary base to control the pH of the reactor; solution C is the main base with a fixed flow rate of 1L / h; the auxiliary base is hydrogen with a concentration of 5mol / L Sodium oxide solution controls the pH of the reactor, and the solution A flow rate is 3L / h. Control the temperature of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com