Method for producing magnetic hollow silicon dioxide particle

A technology of hollow silica and silica, applied in the direction of microsphere preparation, microcapsule preparation, etc., can solve the problem of affecting the stability of the emulsion, the size of the dispersed phase, the type of emulsion, the magnetic properties of the product that affects the stability of the emulsion, and it is not suitable for magnetic hollow Particles and other problems, it is not easy to achieve magnetic properties, low cost, and avoid changes in magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

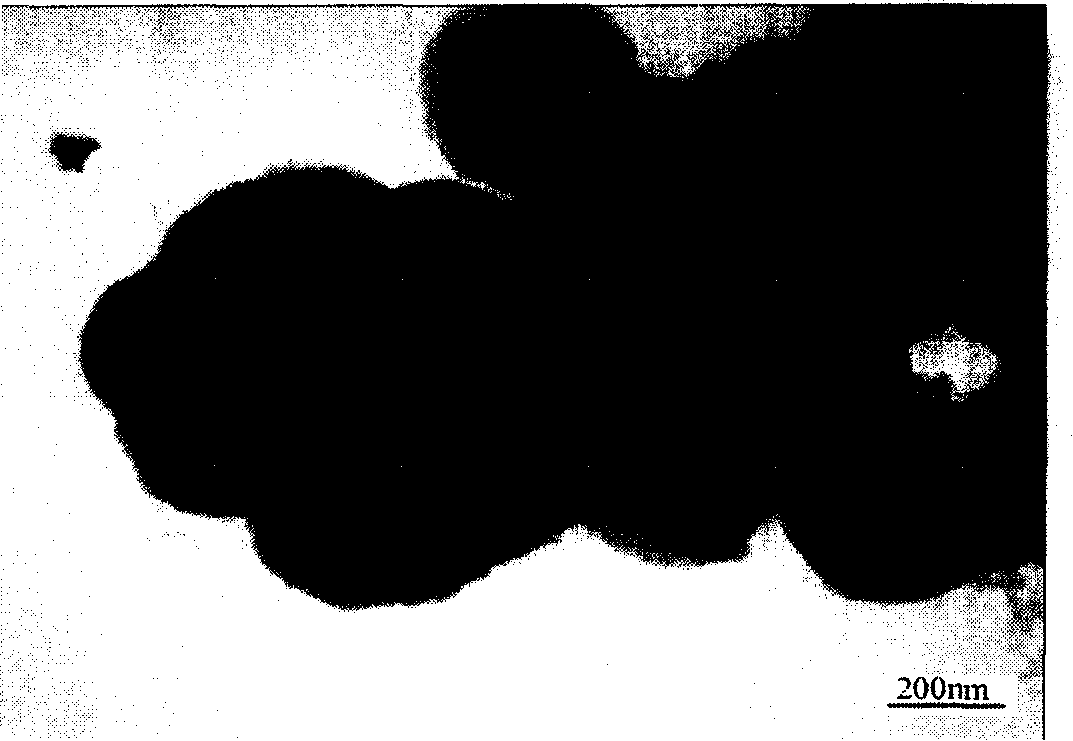

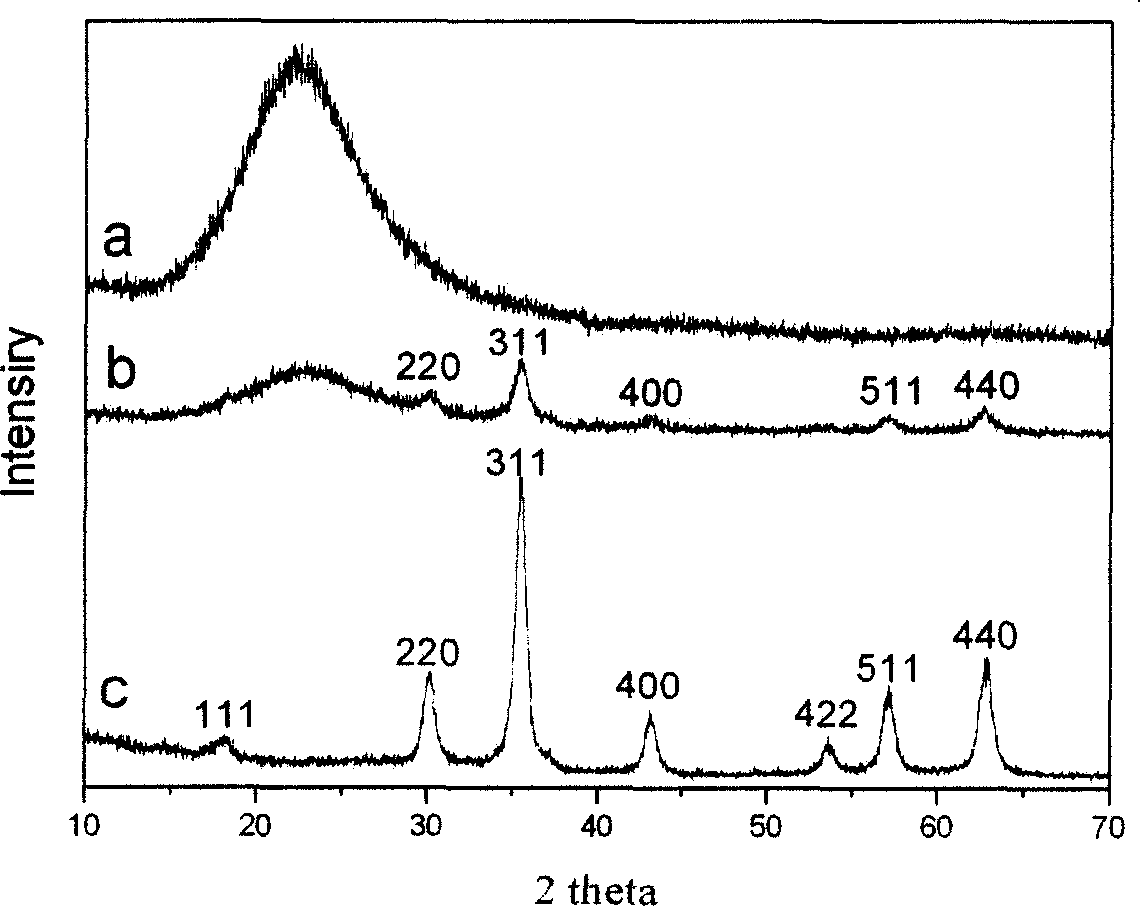

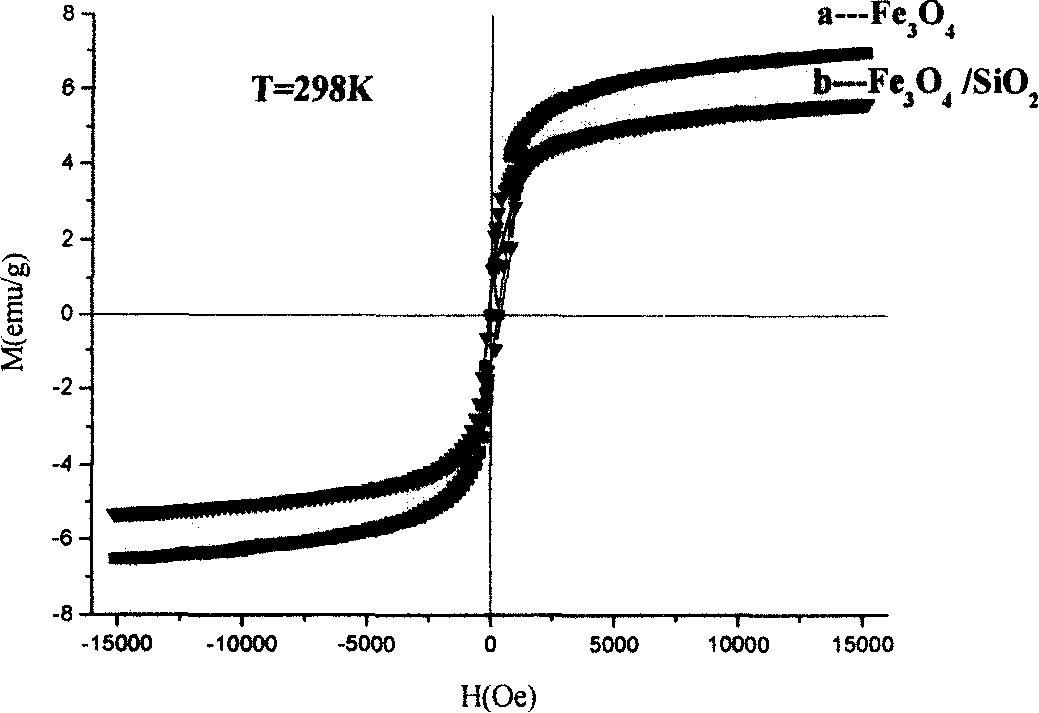

[0021] 1) Slowly add 80 mL of NaOH solution with a concentration of 0.5 mol / L to 50 mL of FeCl containing 0.1 mol / L 2 and 0.2mol / L FeCl 3 In the mixed aqueous solution, stir vigorously, and the pH is controlled between 10-11 to obtain superparamagnetic nano-Fe 3 o 4 The suspension was stirred at 30°C for 30min. Observation of Fe by TEM 3 o 4 The particle size is 8-10nm, and the dispersion is good. The test results of the vibrating sample magnetometer show that the nano-Fe 3 o 4 The particles are superparamagnetic. Add 10ml of cyclohexane to the suspension, and emulsify with a high-speed mixer for 10 minutes to obtain a black oil-in-water emulsion. Take a drop of the emulsion and drop it on a slide, and observe it with an optical microscope. The size of the emulsion droplet is 0.6-2 μm.

[0022] 2) Mix 18.6g TEOS, 3.45g ethanol and 1.8g deionized water, and stir magnetically at 30°C for 21h to obtain SiO 2 Water sol, adding the water sol to the emulsion prepared in step...

Embodiment 2

[0024] 1) Slowly add 80 mL of NaOH solution with a concentration of 0.5 mol / L to 50 mL of FeCl containing 0.1 mol / L 2 and 0.2mol / LFeCl3 In the mixed aqueous solution, stir vigorously, and the pH is controlled between 10-11 to obtain superparamagnetic nano-Fe 3 o 4 The suspension was stirred at 30°C for 30min. Add 10ml of cyclohexane to the suspension, and emulsify with an ultrasonic cell pulverizer for 5 minutes to obtain a black oil-in-water emulsion. Take a drop of the emulsion and drop it on a slide, and observe it with an optical microscope. The droplet size is 0.3-1.2 μm, and the liquid There is a layer of nano-Fe on the surface of the droplet 3 o 4 Particles form a solid film.

[0025] 2) Same as step 2 of Example 1. Finally, a superparamagnetic Fe with a diameter of 580 nm and a shell thickness of 41 nm was obtained 3 o 4 / SiO 2 Composite hollow microspheres.

Embodiment 3

[0027] 1) Slowly add 80 mL of NaOH solution with a concentration of 0.5 mol / L to 50 mL of FeCl containing 0.1 mol / L 2 and 0.2mol / LFeCl 3 In the mixed aqueous solution, stir vigorously, and the pH is controlled between 10-11 to obtain superparamagnetic nano-Fe 3 o 4 The suspension was stirred at 30°C for 30min. Add 10ml of cyclohexane to the suspension, and emulsify for 5 minutes with a high-gravity rotating bed to obtain a black oil-in-water emulsion. Take a drop of the emulsion and drop it on a slide, and observe it with an optical microscope. The droplet size is 0.1-0.5nm.

[0028] 2) Same as step 2 of Example 1. Finally, a superparamagnetic Fe with a diameter of 380 nm and a shell thickness of 40 nm was obtained 3 o 4 / SiO 2 Composite hollow microsphere particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com