Heavy metal polluted bottom mud efficient curing material prepared based on coal-based solid waste

A technology for polluting sediment and solidifying materials, applied in cement production, etc., can solve problems such as secondary pollution, inability to use agricultural production, and heavy metal pollution, and achieve the effects of low price, reduced activity of heavy metals, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

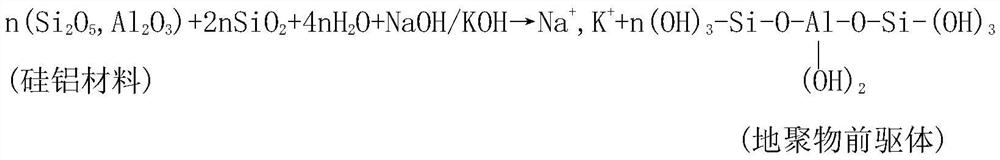

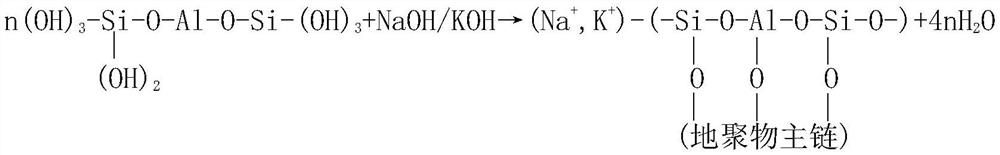

Method used

Image

Examples

Embodiment 1

[0019] This embodiment discloses a method for solidifying heavy metal-contaminated sediment with high-efficiency solidification material prepared based on coal-based solid waste and using it to solidify the sediment.

[0020] Solidification materials include: coal-based solid waste powder, calcium oxide, composite activator and water. Wherein, the composite activator is water glass and potassium hydroxide, the modulus of water glass is 1.03, and the mass of water glass and potassium hydroxide is 4:1.

[0021] The method for curing material curing cement comprises the steps of:

[0022] S1. Calcining coal gangue at 800°C for 2 hours;

[0023] S2. cooling, crushing and pulverizing the calcined coal gangue to 300 mesh to obtain coal gangue powder;

[0024] S3. Take by weighing 172.8g of water glass and 43.2g of potassium hydroxide, and mix it into a composite activator;

[0025] S4. 400g of bottom mud with a water content of 50%, 100g of coal gangue powder, 24g of calcium oxid...

Embodiment 2

[0035] This embodiment discloses a method for solidifying heavy metal-contaminated sediment with high-efficiency solidification material prepared based on coal-based solid waste and using it to solidify the sediment.

[0036] Solidification materials include: coal-based solid waste powder, calcium oxide, composite activator and water. Wherein, the composite activator is water glass and potassium hydroxide, the modulus of water glass is 1.03, and the mass of water glass and potassium hydroxide is 4:1.

[0037] The method for curing material curing cement comprises the steps of:

[0038] S1. Calcining coal gangue at 800°C for 2 hours;

[0039] S2. cooling, crushing and pulverizing the calcined coal gangue to 300 mesh to obtain coal gangue powder;

[0040] S3. Take by weighing 172.8g of water glass and 43.2g of potassium hydroxide, and mix it into a composite activator;

[0041] S4. 500g of bottom mud with a water content of 60%, 100g of coal gangue powder, 24g of calcium oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com