Method for preparing microporous aluminum-silicon-calcium thermal insulation material by autoclaved activation of Bayer process red mud

A technology of Bayer process red mud and thermal insulation material, which is applied in the field of autoclaving activated Bayer process red mud to prepare microporous aluminum-silicon-calcium thermal insulation materials, and achieves the effects of reducing product damage, indicating strength and ensuring stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

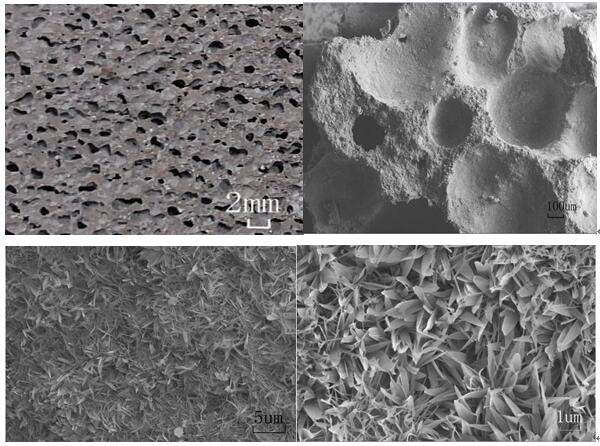

Image

Examples

Embodiment 1

[0027] Powder material raw material composition: red mud 8kg, fly ash 45kg, cement 10kg, lime 8kg, gypsum 2kg; the amount of water added is 45% of the total weight of the powder material.

[0028] The method for preparing microporous aluminum-silicon-calcium thermal insulation material by autoclaving activated Bayer process red mud comprises the following steps:

[0029] Add the powder material into water and stir, and after stirring evenly to form a slurry, foam at 40°C for 8 hours under normal pressure, and then steam for 6 hours under 0.8MPa pressure, and the steam temperature is 170°C.

[0030] The microporous aluminum-silicon-calcium thermal insulation material was prepared with the formula and preparation method of Example 1, and the prepared microporous aluminum-silicon-calcium thermal insulation material was tested and found to have a density of 555kg / m 3 , the strength is 4.2MPa, and the thermal conductivity is 0.1080W / mK.

Embodiment 2

[0032] Raw material composition of powder material: 20kg of red mud, 70kg of fly ash, 25kg of cement, 12kg of lime, 5kg of gypsum; the amount of water added is 70% of the total weight of the powder material.

[0033] The method for preparing microporous aluminum-silicon-calcium thermal insulation material by autoclaving activated Bayer process red mud comprises the following steps:

[0034] Add the powder material into water and stir, and at the same time add a water reducer equivalent to 0.5% of the weight of the powder material, stir evenly to form a slurry, foam at 60°C under normal pressure for 16 hours, and then steam-cure under 1.4MPa pressure 12h, the water vapor temperature is 195°C.

[0035] The microporous aluminum-silicon-calcium thermal insulation material was prepared with the formula and preparation method of Example 2, and the prepared microporous aluminum-silicon-calcium thermal insulation material was tested and found to have a density of 620kg / m 3 , the stre...

Embodiment 3

[0037] Raw material composition of the powder material: red mud 12kg, fly ash 60kg, cement 16kg, lime 10kg, gypsum 3kg; the amount of water added is 60% of the total weight of the powder material.

[0038] The method for preparing microporous aluminum-silicon-calcium thermal insulation material by autoclaving activated Bayer process red mud comprises the following steps:

[0039] Add the powder material into water and stir, and add a water reducing agent equivalent to 0.3% of the weight of the powder material at the same time, after stirring evenly to form a slurry, foam at 50°C under normal pressure for 12 hours, and then steam curing under 1.1MPa pressure 8h, the water vapor temperature is 184°C.

[0040] The water reducer is polycarboxylate water reducer.

[0041] The microporous aluminum-silicon-calcium thermal insulation material was prepared with the formula and preparation method of Example 3, and the prepared microporous aluminum-silicon-calcium thermal insulation mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com