Fragrance slow-release type damp-proof aluminum foil lining paper and preparation method thereof

An aluminum foil lining paper, slow-release technology, applied in the field of papermaking, can solve the problems of slow and stable release of flavoring agents, and achieve the effects of reducing water content, inhibiting mold growth, enhancing flavoring and preventing moisture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

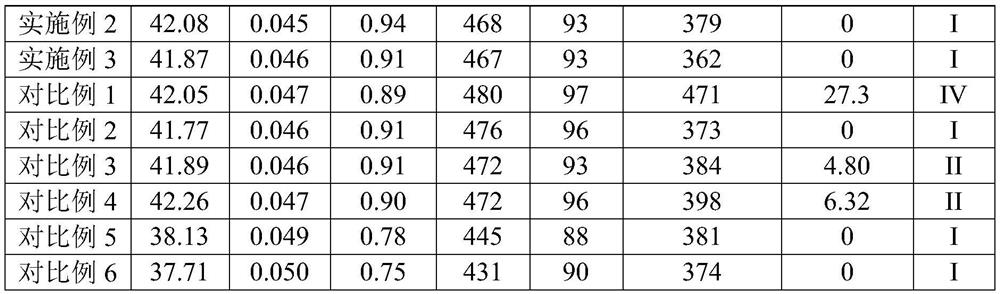

Examples

Embodiment 1

[0059] A flavor slow-release moisture-proof aluminum foil backing paper, comprising the following raw materials: coniferous wood pulp, hardwood pulp, talcum powder, cationic starch, moisture-proof and flavor-enhancing microcapsules, and alkenyl succinic anhydride. The mass ratio of the softwood pulp and the hardwood pulp is 1:2.5; the quality of the talcum powder is 15% of the total dry weight of the softwood pulp and the hardwood pulp; 1% of the total dry weight of leaf wood pulp; the consumption of the moisture-proof and flavor-enhancing microcapsules is 0.3% of the total dry weight of softwood pulp and hardwood pulp; the consumption of described alkenyl succinic anhydride is the total dry weight of softwood pulp and hardwood pulp. 1.5% of dry weight.

[0060] The moisture-proof and flavor-enhancing microcapsules include the following three layers from the inside to the outside: the core of the flavor enhancer, the sodium alginate / nano mineral crystal composite wall layer, a...

Embodiment 2

[0075] A flavor slow-release moisture-proof aluminum foil backing paper, comprising the following raw materials: coniferous wood pulp, hardwood pulp, talcum powder, cationic starch, moisture-proof and flavor-enhancing microcapsules, and alkenyl succinic anhydride. The mass ratio of the softwood pulp and the hardwood pulp is 1:2; the quality of the talcum powder is 20% of the total dry weight of the softwood pulp and the hardwood pulp; 1.2% of the total dry weight of leaf wood pulp; the consumption of the moisture-proof and flavor-enhancing microcapsules is 0.5% of the total dry weight of softwood pulp and hardwood pulp; the consumption of described alkenyl succinic anhydride is the total dry weight of softwood pulp and hardwood pulp. 1.8% of dry weight.

[0076] The moisture-proof and flavor-enhancing microcapsules include the following three layers from the inside to the outside: the core of the flavor enhancer, the sodium alginate / nano mineral crystal composite wall layer, a...

Embodiment 3

[0091] A flavor slow-release moisture-proof aluminum foil backing paper, comprising the following raw materials: coniferous wood pulp, hardwood pulp, talcum powder, cationic starch, moisture-proof and flavor-enhancing microcapsules, and alkenyl succinic anhydride. The mass ratio of the softwood pulp and the hardwood pulp is 1:1.5; the quality of the talcum powder is 25% of the total dry weight of the softwood pulp and the hardwood pulp; The total dry weight of leaf wood pulp is 1.5%; the consumption of the moisture-proof and flavor-enhancing microcapsules is 0.8% of the total dry weight of softwood pulp and hardwood pulp; the consumption of the alkenyl succinic anhydride is the total dry weight of softwood pulp and hardwood pulp. 2% of the weight.

[0092] The moisture-proof and flavor-enhancing microcapsules include the following three layers from the inside to the outside: the core of the flavor enhancer, the sodium alginate / nano mineral crystal composite wall layer, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| gas permeability | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap