Sample treatment method in industrial production of oral solid preparation medicines

A sample processing and solid preparation technology, which is applied in the field of pharmaceutical preparations and quality control, can solve the problems of affecting quality, not accurately reflecting the actual mixing degree of intermediate products, and not paying attention, so as to achieve the effect of avoiding changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

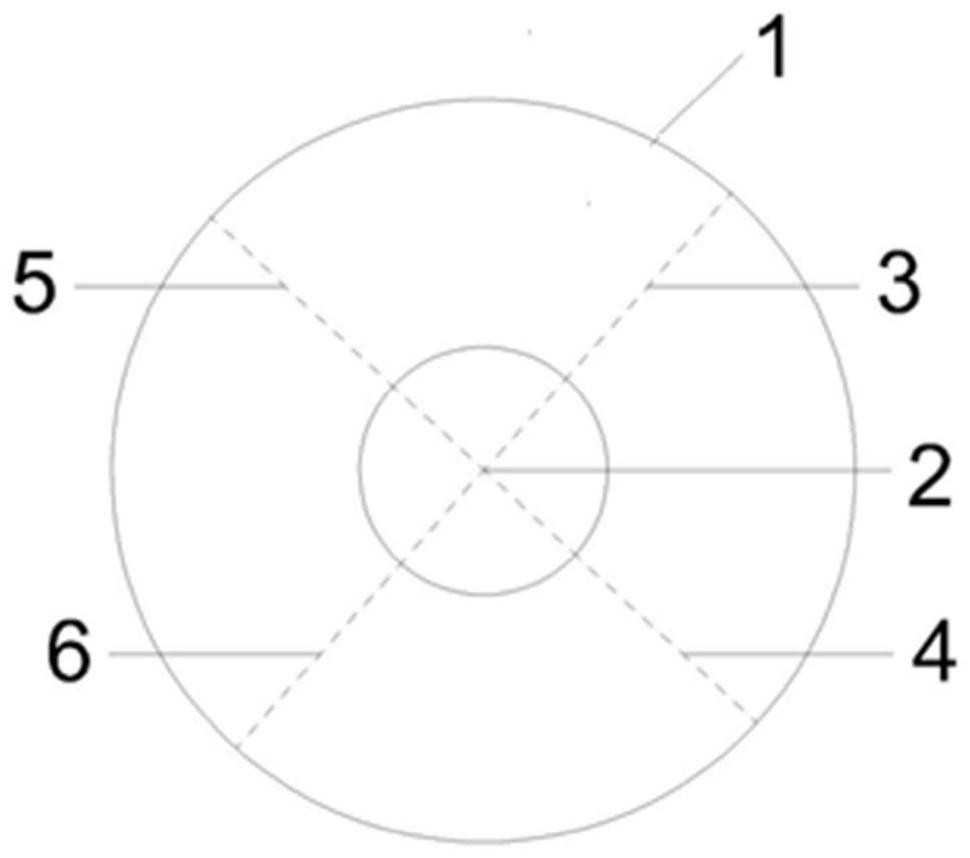

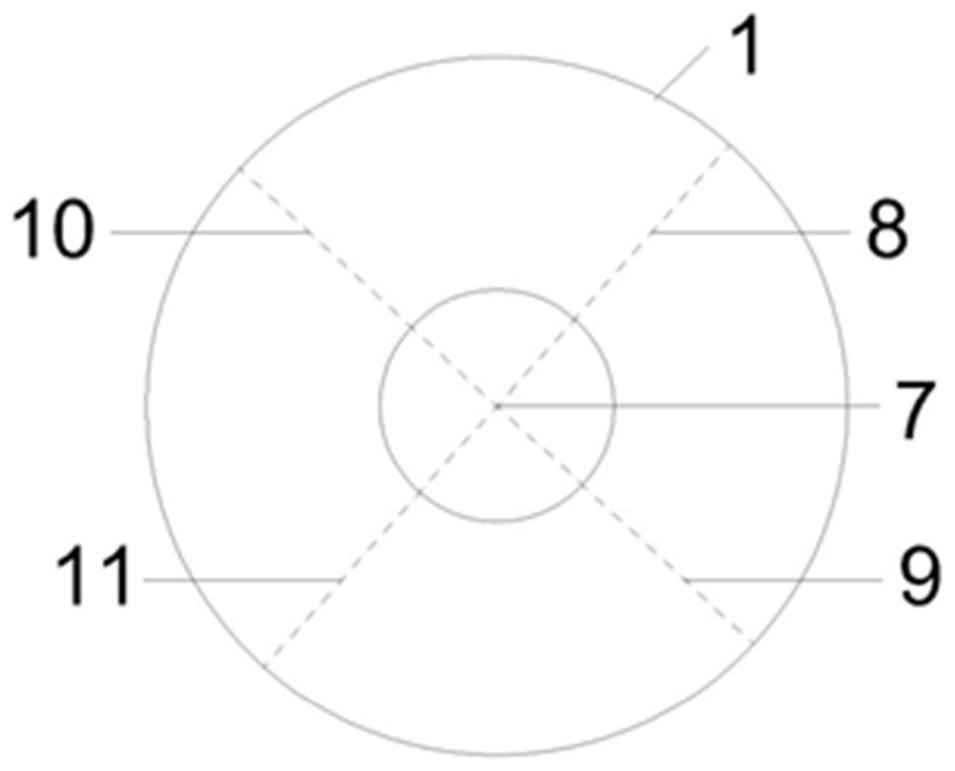

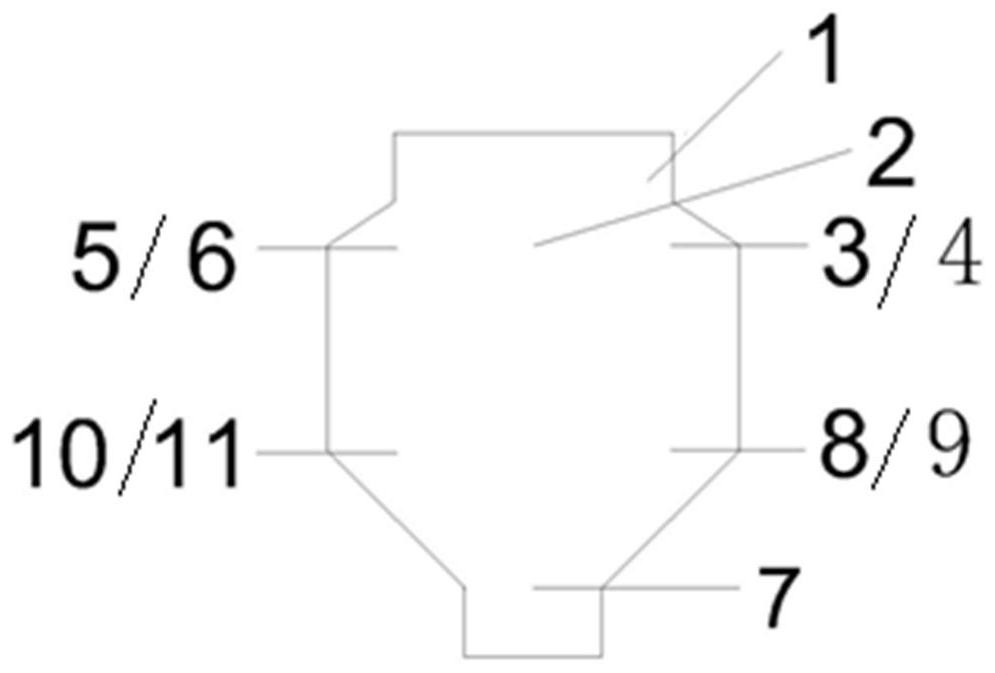

Image

Examples

Embodiment 1

[0069] Example 1 Selection of sampling bags

[0070] Take PE bags with a length of 200 mm, a width of 150 mm, and a single film thickness of 70, 80, 90, 100, 110, 20, 130, and 140 microns, respectively. The length is 200 mm, and the width is 150 mm. 110, 20, 130, 140 micron PVC bags, 200mm long, 150mm wide, PP bags with single film thickness of 70, 80, 90, 100, 110, 20, 130, 140 micron, add 50g starch to each bag. After adding the starch, place it in a vacuum packaging machine for vacuuming to -0.08MPa (displayed by the vacuum packaging machine), observe whether there is a rupture, and make a record. Then heat seal at 120°C for 5 seconds, observe the sealing condition of the bag immediately after the heat sealing is completed, and make a record. The results are shown in Table 1.

[0071] Table 1 Integrity and sealing of different sampling bags

[0072]

[0073]

[0074] The above results show that the PE material bag shows good thermoplasticity and strength, and the...

Embodiment 2

[0075] Example 2 A sample processing method in the industrial production of compound polyethylene glycol electrolyte powder

[0076] Weigh 60kg of polyethylene glycol 4000, 10kg of anhydrous sodium sulfate, 2.5kg of sodium chloride, 1.5kg of potassium chloride, 2.7kg of sodium bicarbonate and 0.1kg of sodium saccharin. Pass all materials through a 60-mesh sieve, add the sieved polyethylene glycol 4000, sodium chloride, potassium chloride, sodium bicarbonate, anhydrous sodium sulfate and sodium saccharin into the lifting mixer, and turn on the mixer at a speed of 10rpm / min, the forward mixing time is 20min, and the reverse mixing time is 20min, the intermediate product to be tested is obtained, and the content uniformity is tested by sampling.

[0077] Each sampling is about 100g, the bulk density of the sample is 0.7g / ml, and the calculated volume of 100g sample is about 143ml. Based on the calculation that the filling volume is 1 / 3 to 2 / 3 of the volume of the PE ziplock b...

Embodiment 3

[0085] Example 3 A sample processing method in the industrial production of Qianggan Capsules:

[0086]Sample 1: Weigh 250g capillary, 125g isatidis, 125g angelica, 125g white peony root, 250g salvia miltiorrhiza, 125g turmeric, 250g astragalus, 125g codonopsis, 125g alisma, 125g sealwort, 125g rehmannia, 125g yam, 100g hawthorn, Liushenqu 100g, Gentiana 100g and Licorice 100g. The above sixteen flavors are decocted three times with water, 1.5 hours for the first time, 1.0 hours for the second and third times, combined decoction, filtered, and the filtrate is added with ammonia test solution to adjust the pH value to 8, filtered, and the filtrate is concentrated under reduced pressure to Thick paste with a relative density of 1.15-1.25 (75°C), dried below 75°C, crushed, added appropriate amount of starch, placed in a mixer, the mixing speed is 6rpm / min, the forward mixing time is 15min, and the reverse mixing time is 15min. (total mixing 30min).

[0087] Sample 2: Weigh 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com