A liquid density measurement device and measurement method based on side hole optical fiber

An edge-hole optical fiber and liquid density technology, which is used in measuring devices, specific gravity measurement, instruments, etc., can solve the problems of strict and complicated manufacturing process of ultrasonic probes, poor anti-interference ability, and inability to measure the density of trace liquids. Detection, effect of small liquid volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

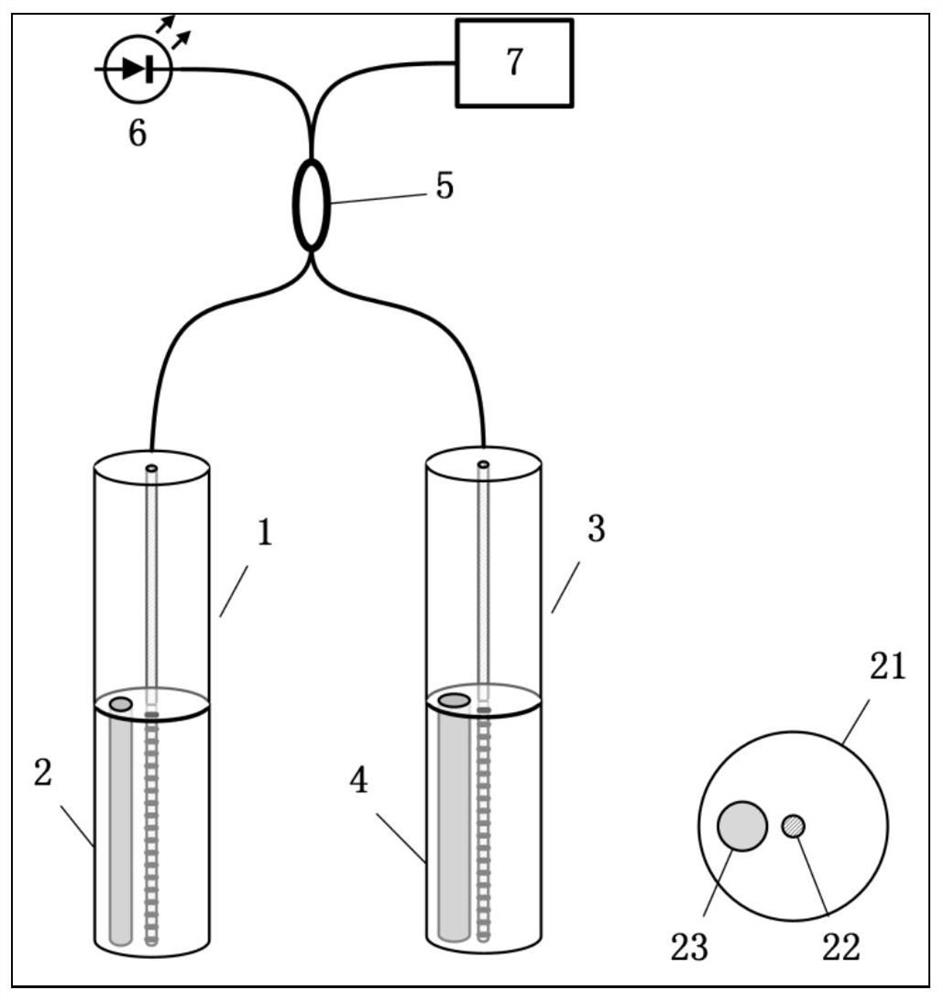

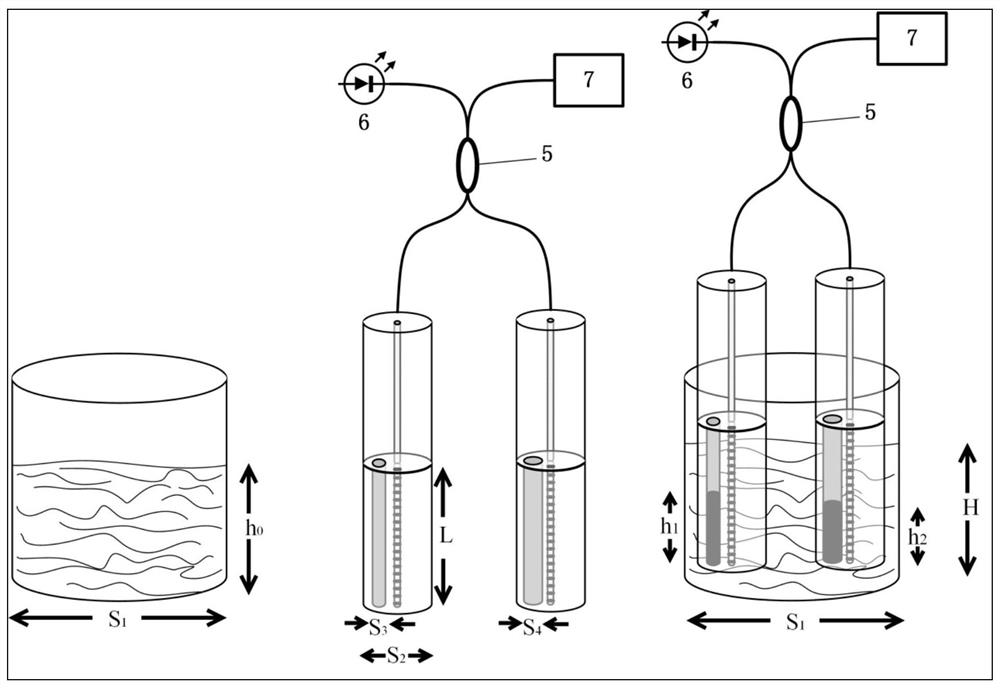

[0019] With the gradual maturity of fiber drawing technology, especially the side hole fiber drawing process of various parameters is becoming more and more perfect, the consistency of side hole fiber distribution along the axial direction is getting closer to the ideal parameter state, so for the devices that need to be used Side hole fiber (such as figure 1 2 and 4) in , can be regarded as an ideal cylinder whose air hole is, such as figure 1 23 in , and its cross-sectional diameter size is known, the cross-sectional area is S 3 and S 4 ,Such as figure 2 shown. The diameter of the outermost layer of the side hole fiber cladding (such as figure 1 21 in) and single-mode fiber (such as figure 1 1) in the same, the cross-sectional area is S 2 , the same size of the two is convenient for fusion splicing and optical signal transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com