Automatic inspection system and automatic inspection method for equipment beside the ground rail

A technology of automatic inspection and trackside equipment, which is applied in office automation, closed-circuit television systems, neural learning methods, etc., can solve the problems of difficult to guarantee the accuracy of image contrast, reduce manual workload, and low degree of intelligence, and achieve Good flexibility and scalability, reduce the labor intensity of employees, and reduce the effect of detection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

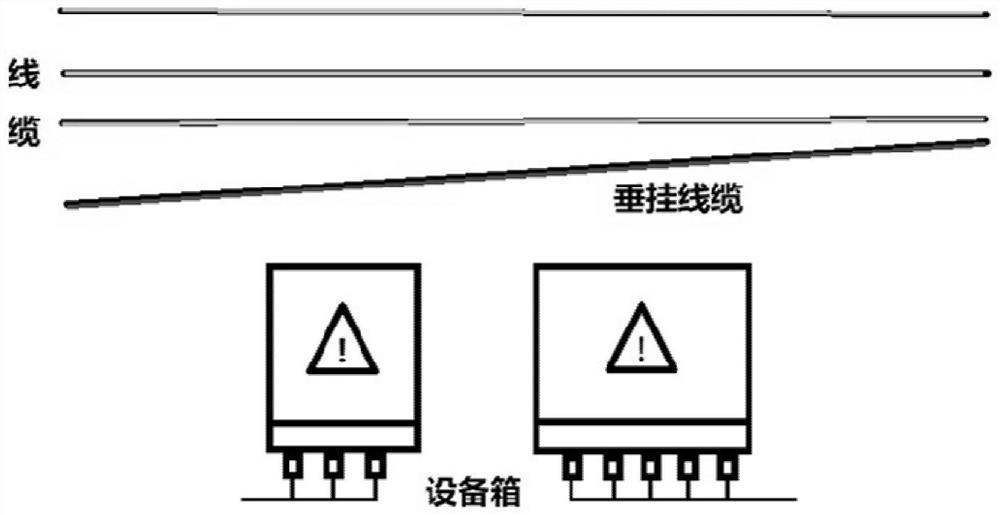

[0077] Check whether the cables in the section are hanging:

[0078] Step S1, the angle of view of the camera on the inspection machine is perpendicular to the wall to shoot the cables on the wall of the subway tunnel;

[0079] Step S2, using the Hough transform in the OpenCV library to detect the straight line in the image, that is, the suspension cable;

[0080] Step S3, calculating the slope of the straight line, if the slope exceeds the set threshold, it is abnormal;

[0081] Such as image 3 As shown in the figure, the cables are marked on the image according to the straight line detection algorithm. The horizontal cables in the normal state are marked in green, and the cables with abnormal slopes are marked in red.

Embodiment 2

[0083] Detect if the equipment box door is open:

[0084] Step S1, mark the side gap of the equipment box with a specific color in advance, and when the equipment box door is opened, the marks will be staggered to present an abnormal state;

[0085] Step S2. The angle of view of the camera on the inspection machine is at a certain angle to the wall of the subway tunnel to shoot the side of the equipment box; under normal circumstances, the angle of view of the center of the camera and the direction of the train is at an angle of 60 degrees to the tunnel wall. Properly adjust the shooting angle;

[0086] Step S3, realize the precise positioning of the equipment box through deep learning training on the appearance of the equipment box, and narrow the detection area;

[0087] Step S4, constructing a color mask corresponding to the mark color through HSV color space segmentation to realize mark form extraction;

[0088] Step S5: Carry out binary classification training on the ma...

Embodiment 3

[0090] Detect whether the terminal of the equipment is disconnected:

[0091] Step S1, the camera angle of view on the inspection machine is perpendicular to the subway tunnel wall to shoot the equipment on the wall;

[0092] Step S2, using the original yellow label at the end of the terminal, through HSV color space segmentation, constructing a yellow mask to filter out the yellow label, eliminating the interference of complex backgrounds;

[0093] Step S3, calling the cv2.findContours() algorithm to mark the connected regions in the image (labeled regions are regarded as independent connected regions) and counting;

[0094] Step S4, comparing with the number of terminals recorded in the database, if they are inconsistent, it is abnormal;

[0095] Such as Figure 4 As shown, the system counts the terminals on the device, the labels below the terminals are marked and the total is displayed on the screen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com