Metal catalyst and its mass production preparation method and fuel cell

A technology of metal catalysts and fuel cells, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of unsatisfactory metal catalytic activity, appropriate particle size, difficulty in mass production and high dispersion, and achieve catalytic performance and structure Stability, improved electrochemical performance, and uniform morphology and particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

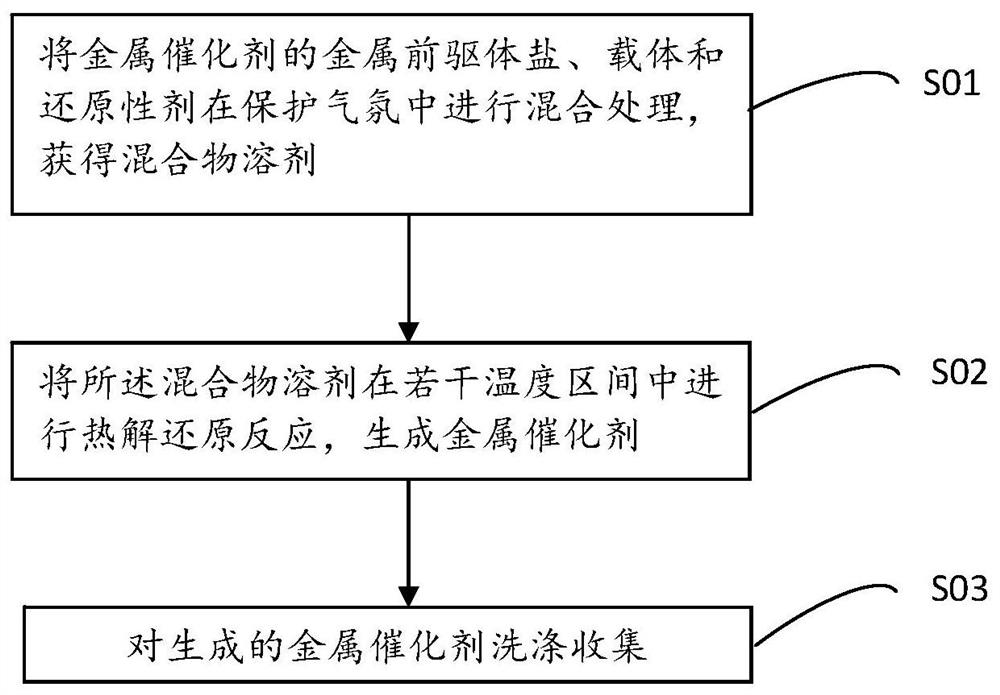

[0024] On the one hand, the embodiment of the present invention provides a mass production preparation method of a metal catalyst. The process flow of the mass production preparation method of the metal catalyst is as follows: figure 1 shown, including the following steps:

[0025] S01. Mixing the metal precursor salt of the metal catalyst, the carrier and the reducing solvent in a protective atmosphere to obtain a mixture solvent;

[0026] S02. The mixture solvent is subjected to a pyrolysis reduction reaction in several temperature intervals to generate a metal catalyst; wherein, the temperature in the several temperature intervals increases from a low to high gradient, and the mixture solvent increases from a low temperature interval to a The pyrolysis reduction reaction is carried out under dynamic heating in the high temperature range.

[0027] In this way, the method for preparing the mass production of the metal catalyst is to dynamically heat the mixture solvent of t...

Embodiment 1

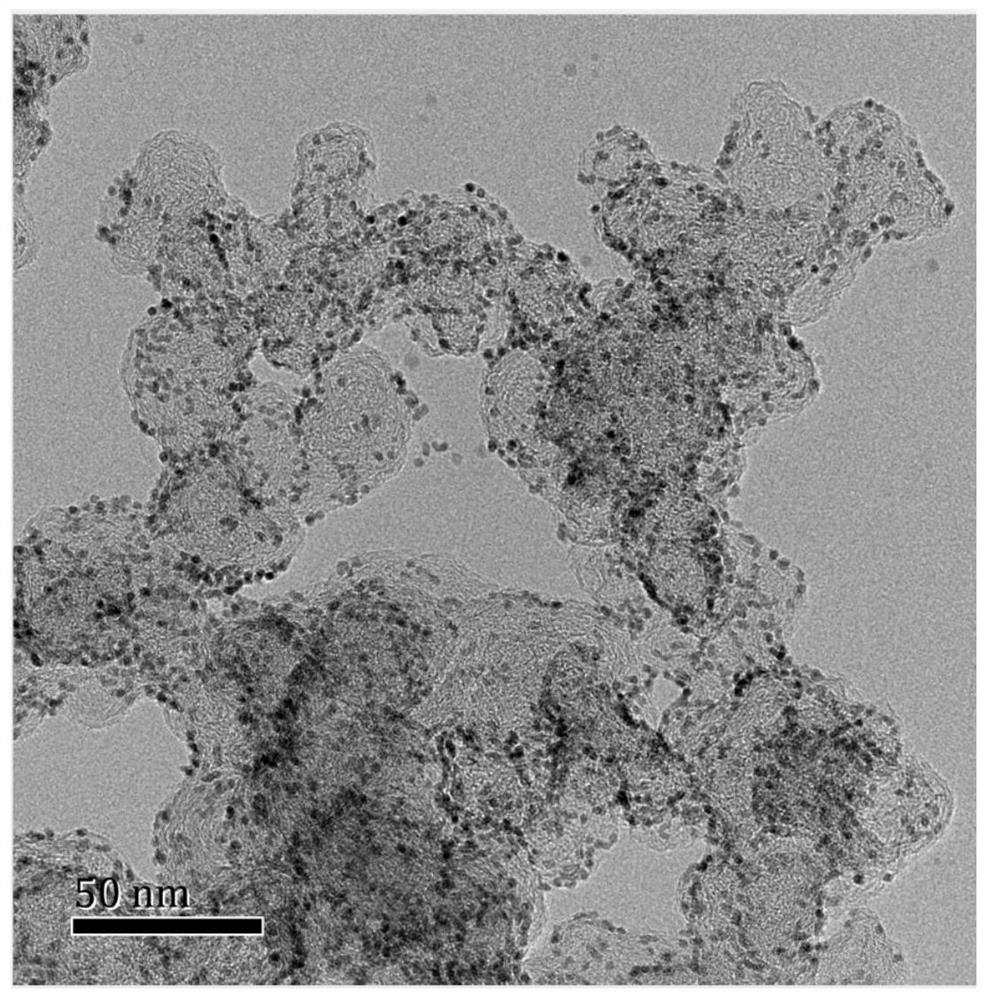

[0048] This embodiment provides a Pt / C catalyst metal catalyst and its preparation method for mass production. The mass production preparation method of the metal catalyst comprises the following specific steps:

[0049] S1: Take 1.05g Pt(acac) 2 Add 2g of carbon black powder to 600 ml of mixed liquid solution of oleylamine and oleic acid, and ultrasonically disperse for about 1 hour to prepare a black mixed solution;

[0050] S2: Add the prepared black mixed solution into container A, 2 After stirring for 15 minutes under protection, heat the mixed solution to 100°C;

[0051] S3: Pass the mixed solution in container A through different reaction temperature zones B-E at a flow rate of 3ml / min. The temperatures of reaction temperature zones B-E are respectively set as: 110°C, 130°C, 160°C, 220°C;

[0052] S4: washing the catalyst in the drying container F to obtain Pt / C catalyst powder.

Embodiment 2

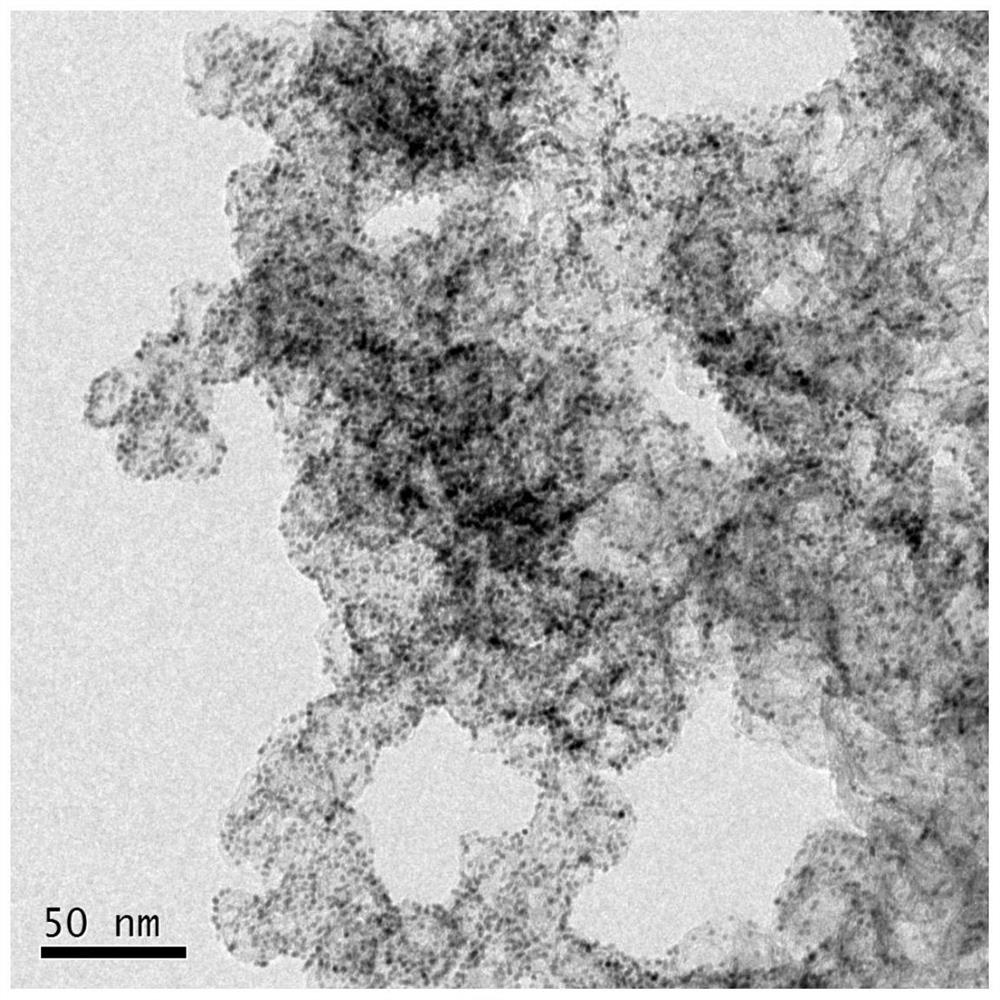

[0054] This embodiment provides a Pt 3 Ni / C metal catalyst and its preparation method for mass production. The mass production preparation method of the metal catalyst comprises the following specific steps:

[0055] S1: take 0.53g Pt(acac)2, 0.12g Ni(acac) 2 Add 1g of carbon black powder to 400 ml of mixed liquid solution of oleylamine and oleic acid, and ultrasonically disperse for about 1 hour to prepare a black mixed solution;

[0056] S2: Add the prepared black solution into container A, under N 2 After stirring for 10 minutes under protection, heat the mixed solution to 110°C;

[0057] S3: Pass the mixed solution in container A through different reaction temperature zones B-E at a flow rate of 500ml / min, and set the temperatures of reaction temperature zones B-E as: 130°C, 160°C, 190°C, 260°C;

[0058] S4: washing the catalyst in the drying vessel C to obtain Pt 3 Ni / C catalyst powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com