Composite wave-absorbing material and preparation method thereof

A technology of composite wave-absorbing material and wave-absorbing layer, which is applied in the field of wave-absorbing materials, can solve the problem that wave-absorbing materials cannot have a wide frequency band at the same time, and achieve the effect of good compatibility and good elongation and stretching performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

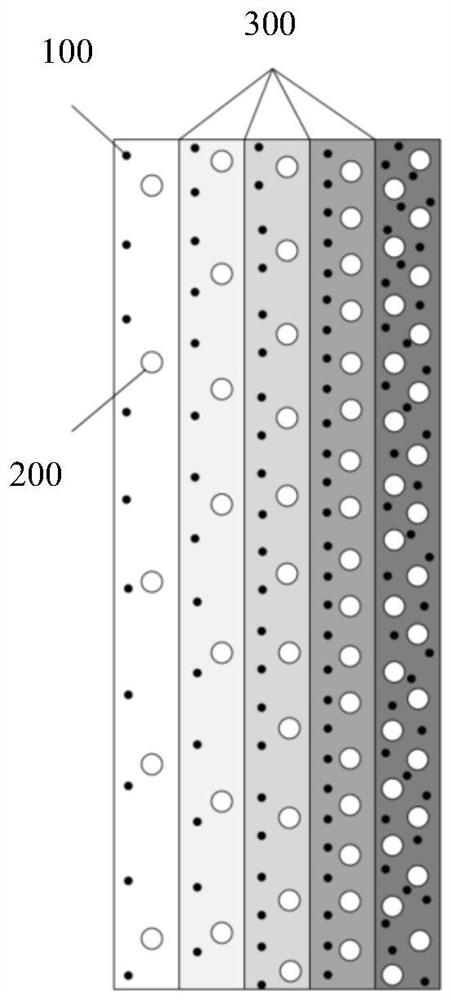

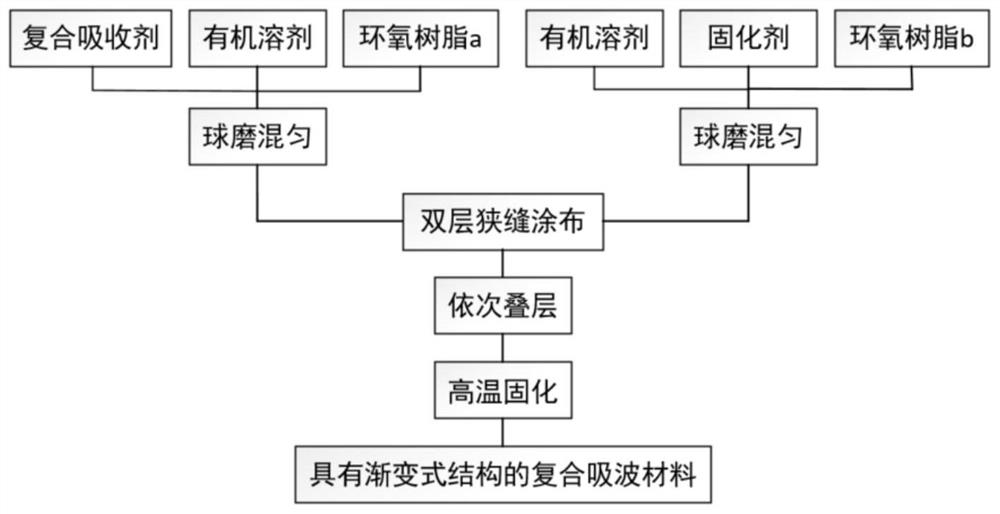

[0035] The absorbing agent used in this example is hydroxyl iron powder and hollow glass microspheres. The curing temperature of epoxy resin a is 130-180°C, and the viscosity at 50°C is 4500-5800mPa·s. The curing temperature of epoxy resin b is The viscosity at 170-200°C and 50°C is 35000-42000mPa·s. The structure diagram of the prepared composite absorbing material is as follows figure 1 As shown, 100 is hydroxyl iron powder, 200 is hollow glass microspheres, and 300 is epoxy resin layer. The preparation process refers to figure 2 , specifically prepared according to the following steps:

[0036] 5 grams of hydroxyl iron powder, 3 grams of hollow glass microspheres, 100 grams of epoxy resin a, and 16 milliliters of organic solvent (by mixing ethyl acetate and N,N-dimethylformamide at 1:1) were added to the In the tank body of the planetary ball mill, ball mill for 3 hours at a speed of 350r / min, and the filtered slurry is sealed for subsequent use. The above slurry is deno...

Embodiment 2

[0047] The absorbing agent used in this example is iron nitride and activated carbon fiber, the mass ratio of iron nitride and activated carbon fiber is 10:1, the curing temperature of epoxy resin a is 130-180°C, and the viscosity at 50°C is 2000- 8000mPa·s, the curing temperature of epoxy resin b is 170-200°C, and the viscosity at 50°C is 20000-70000mPa·s. It is prepared according to the preparation steps of Example 1, and the proportions of wave-absorbing agents in different wave-absorbing layers are respectively 10%, 25%, 40%, 55%, 70%, 85%, the thickness of a single double-layer raw tape is 150 μm, and the thickness of the multilayer composite absorbing material obtained after lamination and curing is about 700 μm, and It can be flexibly adjusted according to actual needs.

Embodiment 3

[0049] The wave absorbing agent used in this example is sendust powder and carbon nanotubes, the ratio of sendust powder to carbon nanotubes is 15:1, the curing temperature of epoxy resin a is 130-180°C, and the viscosity is 50°C is 2000-8000mPa·s, the curing temperature of epoxy resin b is 170-200°C, and the viscosity at 50°C is 20000-70000mPa·s. It is prepared according to the preparation steps of Example 1, wherein the proportions of wave-absorbing agents in different wave-absorbing layers The ratios are 5%, 20%, 35%, 50%, 65%, and 80%, respectively. The thickness of a single double-layer raw tape is 150 μm, and the thickness of the multilayer composite absorbing material obtained after lamination and curing is about 1100μm, and can be flexibly adjusted according to actual needs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com