Vacuum intermittent excrement collecting system for locomotive, working method thereof and locomotive toilet

An intermittent, vacuum technology, applied in the field of locomotive toilets, can solve problems such as adverse effects on service life, poor airtightness, and backward technology, and achieve a good pressure guarantee effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

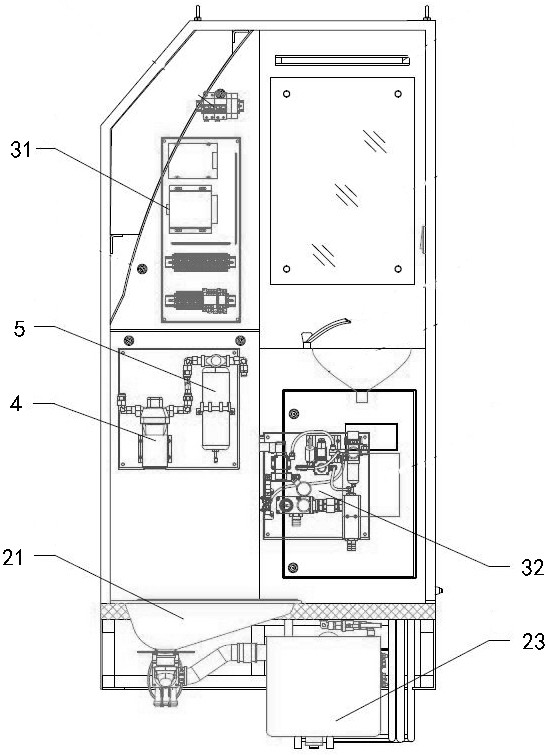

[0037] Such as figure 1 and figure 2 As shown, a locomotive toilet is provided, including a toilet shell 11, a door assembly 12, a display panel 13, a vacuum intermittent defecation system, a sewage pipeline under the vehicle, a wash basin, a mirror, a lighting lamp, a faucet, an armrest, and a toilet paper holder , trash can, electric heater, exhaust fan, triangular lock, triple switch, water supply pipeline and water supply pipeline, etc., wherein the vacuum intermittent toilet collection system includes a bedpan 21, a clean water tank 22 that can deliver flushing water to the bedpan, and In the dirt tank 23 for receiving flushing materials in the bedpan, there are a plurality of flushing water inlets (not shown) evenly distributed at the mouth of the potty, and nozzles are arranged in the flushing water inlets, and the toilet flushing water outlet and the dirt tank 23 pass through The drain valve 24 is connected, a vacuum generator 25 is provided on the dirt tank 23, and ...

Embodiment 2

[0046] This embodiment provides a working method of the vacuum intermittent feces collection system in Embodiment 1. The entire working process of the feces collection system includes five continuous actions, which are standby state, vacuum pumping action, bedpan flushing action, and bedpan emptying action And the second flushing action of the bedpan, the steps for these states are analyzed as follows:

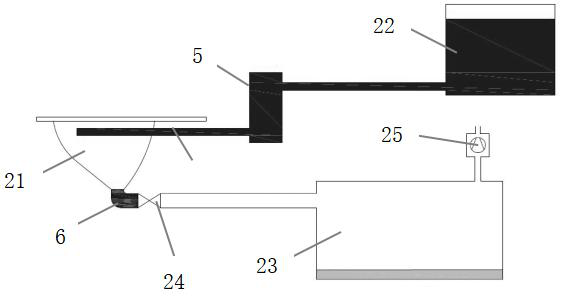

[0047] In the standby state, such as image 3 Shown, the L-shaped pipeline 6 at the bottom of the energy storage tank 5 and the bedpan is all in the state of being full of water, and the dirt tank 23 is in a normal pressure state.

[0048] S1. The user presses the flushing button 26. Generally, the duration of pressing the button is about 0.5s. The control module sends a signal to drive the vacuum generator to generate a vacuum between the discharge valve 24 and the dirt box 23, such as Figure 4 As shown, this is the vacuuming action.

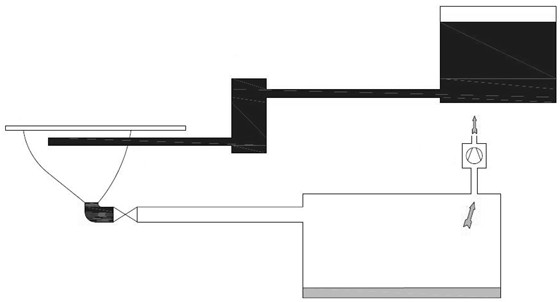

[0049] S2. The control module synchro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com