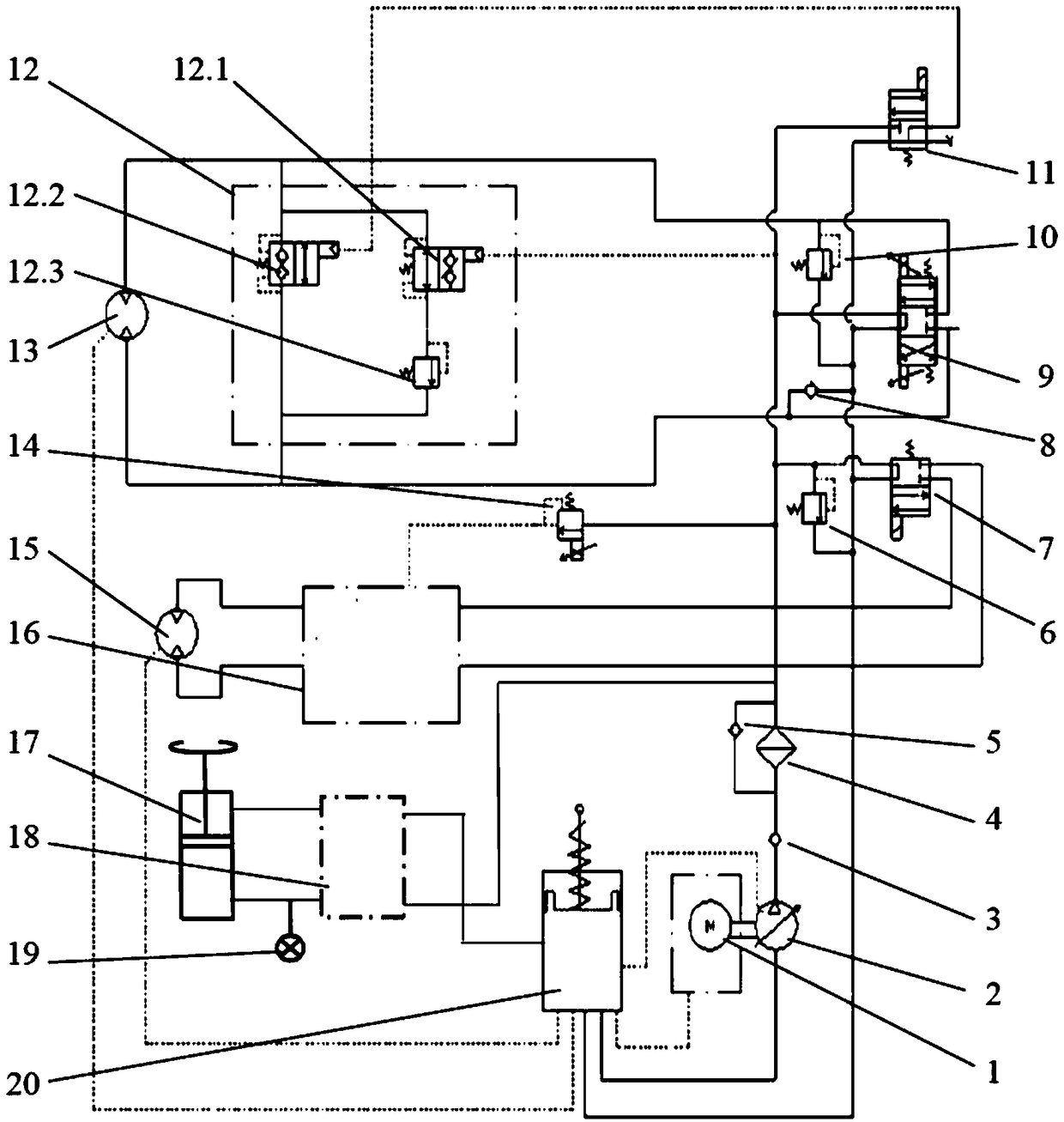

Deep sea cable winding and unwinding hydraulic system

A hydraulic control system and cable technology, applied in the field of deep sea hydraulics, can solve the problems of accelerated reel rotation speed, system heating, no anti-overspeed, etc., and achieve the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical solutions and advantages of the present invention clearer, the exemplary embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Apparently, the described embodiments are only a part of the embodiments of the present invention, and are not exhaustive of all the embodiments. And in the case of no conflict, the embodiments and the features in the embodiments of the present invention can be combined with each other.

[0043] In the course of the invention, the inventor proposed a technical method using electro-hydraulic control in view of the deficiencies of the mooring cable retracting and releasing equipment used in the deep sea environment and the mechanical transmission mode currently used in the deep sea, but it was found through experiments that the existing Land and marine deck hydraulic winches are directly transplanted underwater, especially the deep sea environment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com