Industrial robot with automatic feeding and discharging functions and method

An industrial robot and material technology, applied in the stacking of objects, de-stacking of objects, conveyor objects, etc., can solve the problems of increasing the risk of material slipping, overlapping lines, and not using it, so as to reduce the risk of material scattering , the effect of improving production efficiency and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention.

[0031] According to an embodiment of the present invention, an industrial robot with automatic loading and unloading of materials and a method thereof are provided for a drilling device and a production method for producing automobile gearbox gears.

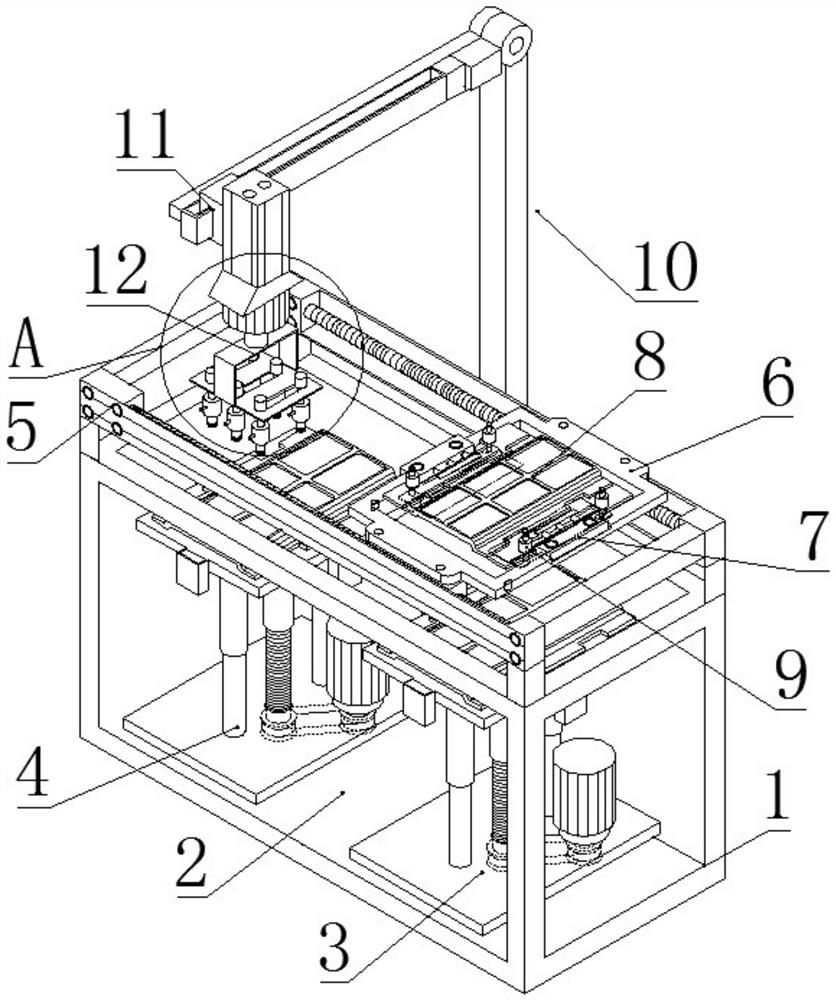

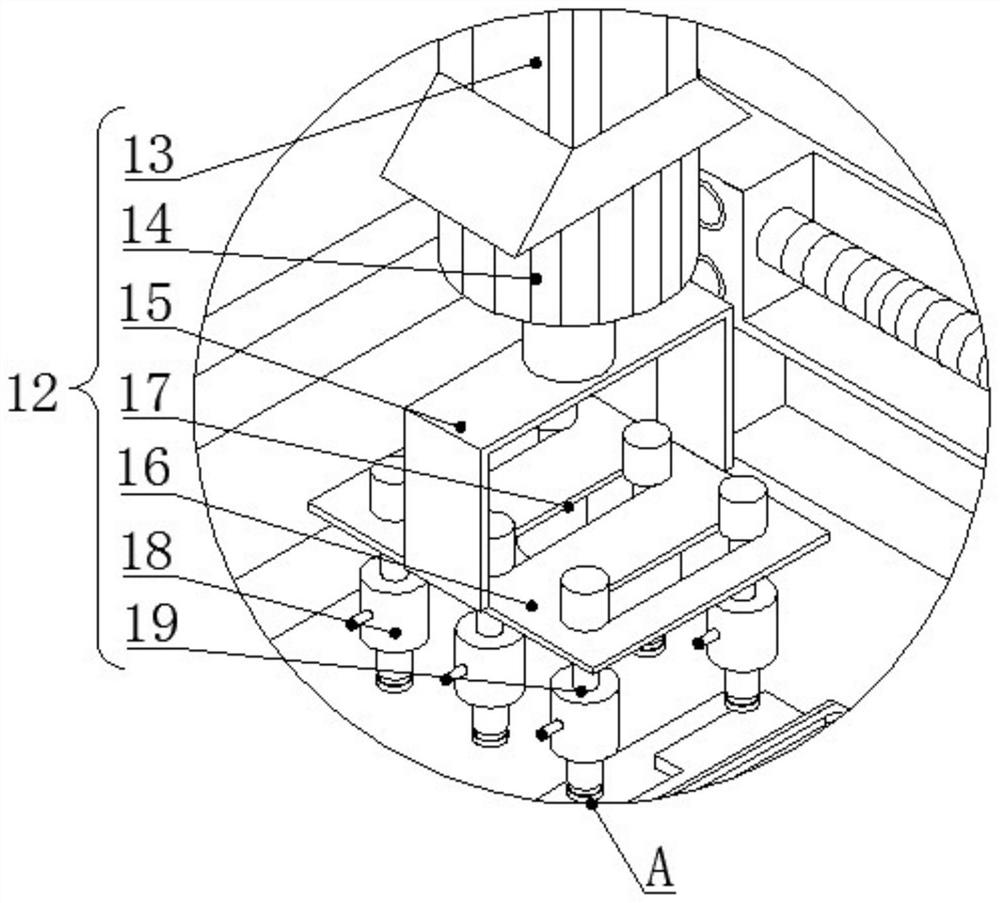

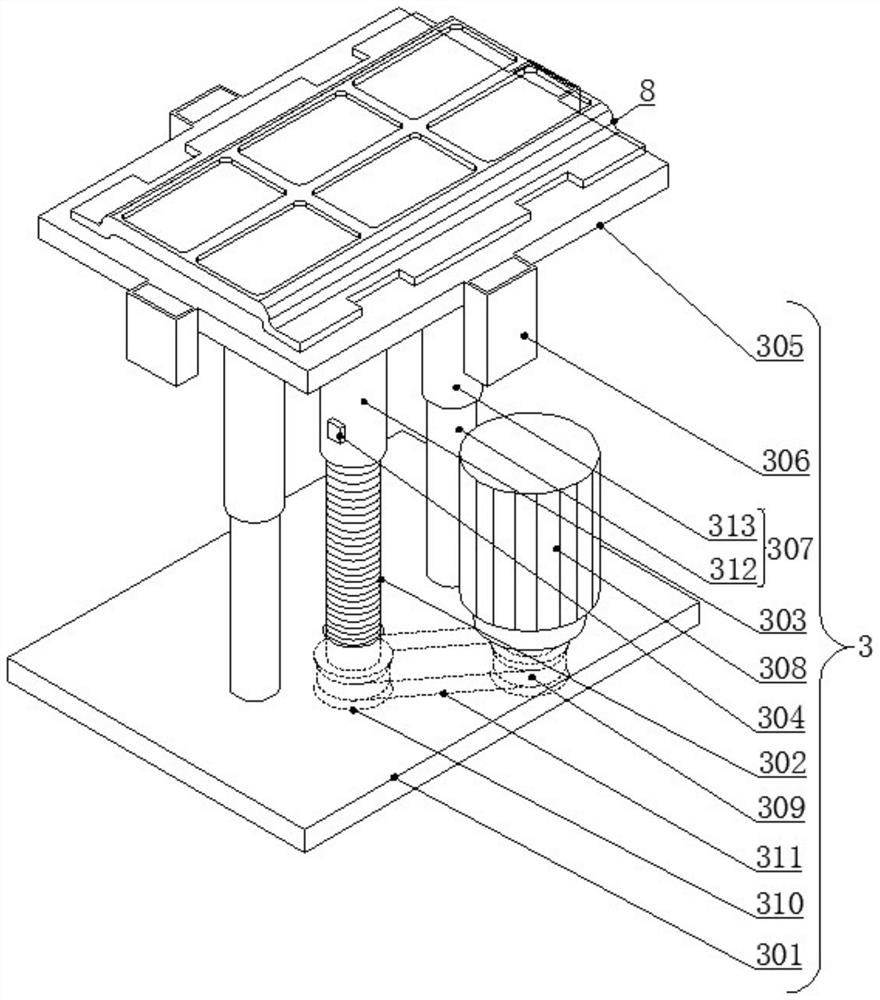

[0032] Such as Figure 1-7 As shown, according to the embodiment of the present invention, a frame 1 is included, and a silo 2 is arranged inside the frame 1, and a feeding assembly 3 and a feeding assembly 4 are symmetrically arranged in the hopper 2, and screw rods are symmetrically arranged on the top of the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com