Integrated sewage treatment and anaerobic ammonia oxidation strain retention system and method

A technology for anaerobic ammonium oxidation and sewage treatment, applied in the field of integrated sewage treatment and anammox bacteria retention system, can solve the problems of low growth rate, simplify the process flow, maintain the abundance of bacteria, save Effect of anaerobic stirring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

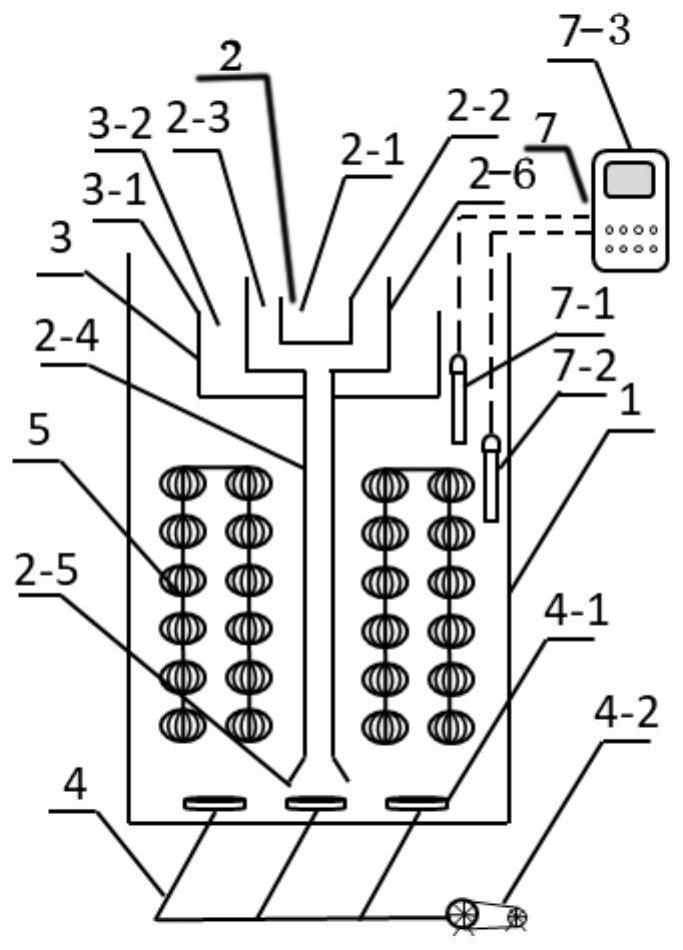

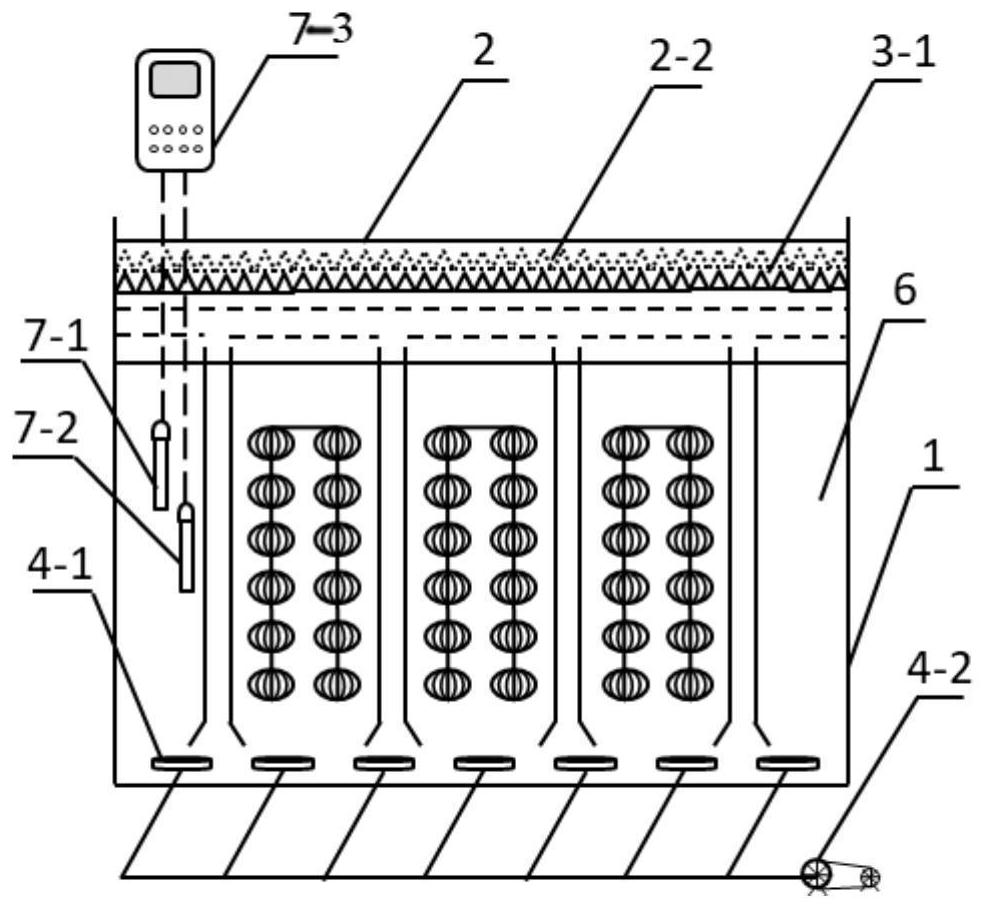

[0058] This embodiment provides an integrated sewage treatment and anammox strain retention system, such as figure 1 , 2 As shown, the system includes a reactor tank body 1, water inlet subsystem 2, water outlet subsystem 3, aeration subsystem 4, biological filler area 5, short-range nitrification sludge 6 and online monitoring subsystem 7;

[0059] The water inlet subsystem 2 is arranged on the upper part of the reactor pool body 1, and the water inlet subsystem 2 includes the water inlet inner channel 2-1, the first water inlet weir 2-2, the water inlet outer channel 2- 3. The second water inlet weir 2-6, a plurality of water inlet vertical pipes 2-4 and a plurality of water distribution horns 2-5; In the middle of the outer canal 2-3;

[0060] The water outlet subsystem 3 includes an outlet weir 3-1 and an outlet channel 3-2; the outlet channel 3-2 is arranged between the outlet weir 3-1 and the second inlet weir 2-6, the A plurality of water inlet vertical pipes 2-4 are...

Embodiment 2

[0066] This example provides a method for integrated treatment of sewage and retention of anammox strains. The sewage to be treated in this example is the effluent from the primary sedimentation tank of Beijing Gaobeidian Recycled Water Plant. The water quality of the effluent from the primary sedimentation tank: COD 106.1-182.4mg / L, NH 4 + -N is 40.24-64.97mg / L, NO 2 - -N is 0.00-1.12mg / L, NO 3 - -N is 0.11-1.19mg / L; SS is 60-138mg / L; TP is 3.13-8.31mg / L; alkalinity is 247-405mg / L; pH is 7.02-7.58.

[0067] The method adopts the integrated sewage treatment and anammox strain retention system described in embodiment 1, comprising the steps of:

[0068] S1: Let the sewage flow into the water inlet channel 2-1, and flow to the bottom of the reactor pool body 1 through the multiple water distribution horns 2-5; control the rising flow rate to 1.0m / h.

[0069] S2: After the water inflow in step S1 is completed, use the aeration subsystem 4 to aerate the sewage, and use the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com